A Xenon Arc Chamber is more than a light exposure device. It is a complex system that integrates light spectrum simulation, temperature and humidity control, water spray, and real-time monitoring to reproduce years of outdoor aging within weeks or months.

In many laboratories, maintenance is treated as a necessary afterthought—lamp replacement, filter cleaning, sensor calibration.

At LIB industry, maintenance is viewed very differently: it is a direct reflection of how well a Xenon Arc Chamber was designed in the first place.

This article explains how routine maintenance points reveal the deeper engineering logic behind LIB industry’s Xenon Arc Chamber—and why that logic leads to more stable, repeatable, and trustworthy test data over long operating cycles.

|

|

| |

What users maintain is the lamp. What LIB industry designs is the entire light system.

At the heart of every Xenon Light Fastness Test Chamber is a high-intensity xenon arc lamp capable of reproducing UV, visible, and infrared portions of natural sunlight. This full-spectrum output is essential for accurately evaluating fading, cracking, embrittlement, or surface degradation of materials.

From a maintenance perspective, lamp replacement is inevitable. From an engineering perspective, however, LIB industry focuses on a deeper question:

How does lamp aging affect irradiance stability and spectral consistency?

To address this, LIB industry designs the Xenon Arc Chamber light system as a coordinated whole:

Stable ignition and discharge behavior reduce stress during frequent start–stop cycles

Controlled thermal management prevents localized overheating that can alter spectral output

Intelligent power regulation compensates for gradual lamp degradation

As a result, during maintenance inspections, users often find that even as lamps approach the later stages of their service life, irradiance levels remain controlled and predictable, reducing the need for frequent manual adjustments.

This is where maintenance confirms design quality—not the other way around.

Model | XL-S-750 |

Internal Dimension (mm) | 950*950*850 mm |

Overall Dimension (mm) | 1400*1400*1950 mm |

Specimen Holder Size(mm) | 95*200 |

Specimen Capacity | 42pcs |

Chamber Type | Rotating Holder |

Irradiation Source | 1 piece of 4500w water-cooled xenon arc lamp |

Irradiance Range | 35~150 W/㎡ |

Bandwidth Measurement | 300nm~400nm (340nm or 420nm) |

Full-spectrum water-cooled xenon arc lamp |

|

Spectral control is not achieved by filters alone—it depends on how they are integrated.

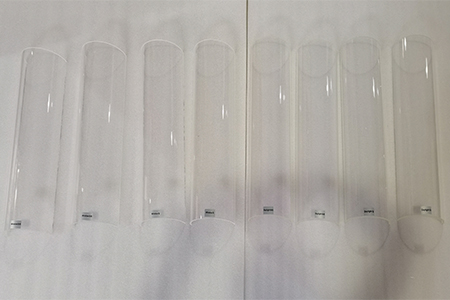

In a Xenon Arc Chamber, optical filters shape the emitted spectrum to match specific testing standards, whether focused on UV weathering, daylight simulation, or material-specific exposure conditions. Over time, filter cleanliness and condition naturally become part of routine maintenance.

LIB industry approaches this from a system perspective:

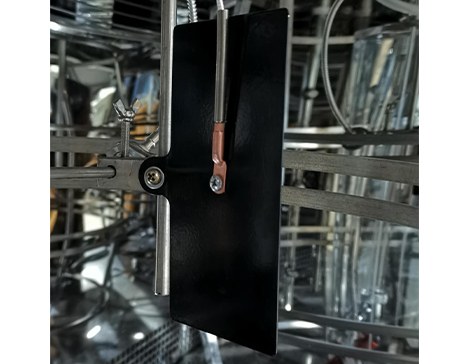

Filters are positioned to maintain consistent optical paths

Structural design minimizes repeated handling and misalignment

Replacement or cleaning is fast, controlled, and repeatable

When users service the filter system on a Xenon Light Fastness Test Chamber, they experience a process designed to remove uncertainty rather than introduce it. The result is long-term spectral stability that remains within controlled tolerances even after extended operation.

For LIB industry, filter maintenance is not about convenience—it is about protecting data integrity.

|

| Daylight, Window, and Extended UV filters |

Accelerated aging is only meaningful when environmental variables remain synchronized.

A Xenon Arc Chamber is expected to regulate multiple parameters simultaneously:

Chamber temperature under intense light load

Relative humidity across a wide operating range

Water spray cycles that simulate rain, condensation, or moisture shock

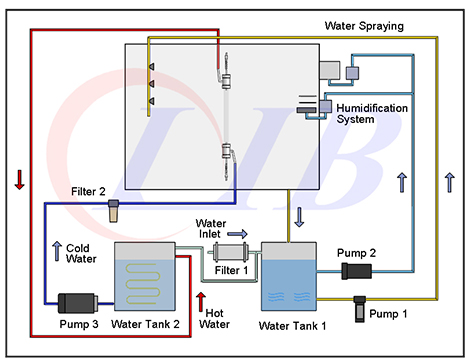

From a maintenance standpoint, this means regular attention to water quality, filtration, and heat exchange efficiency.

From LIB industry’s engineering standpoint, it means designing systems that remain stable under continuous stress.

Water circulation is treated as a core subsystem, supporting:

Lamp cooling

Humidity generation

Spray system operation

By minimizing dead zones and simplifying flow paths, LIB industry reduces the buildup of scale or biological contamination. When users replace filters or clean components, they are maintaining a system that was already optimized for long-term reliability.

The outcome is consistent environmental control—even during high-temperature, high-irradiance test cycles typical of demanding Xenon Light Fastness Test Chamber applications.

Chamber Temperature Range | Ambient ~ 100 ℃ ±2℃ |

Black Panel Temperature | BPT 35 ~ 85 ℃ ±2℃ |

Humidity Range | 50% ~ 98% RH |

Humidity Deviation | ± 5% RH |

Water Spray Cycle | 1~9999H59M (Adjustable) |

Water supply system | Automatic water supply, Water purification system |

Cooling System | Mechanical compression refrigeration system,Environmental-friendly refrigerant |

|  |

Calibration does not fix accuracy—it proves it.

Regular calibration of irradiance and temperature sensors is a standard requirement for any Xenon Arc Chamber. At LIB industry, calibration is not treated as a correction mechanism, but as a verification of system stability.

Multi-point sensors continuously monitor key parameters, while digital control systems log operational and calibration data. During maintenance, this allows users to:

Confirm consistency across different measurement points

Track long-term trends rather than isolated values

Ensure test results remain traceable and auditable

This approach supports compliance with international testing standards and reinforces confidence in long-term test comparability.

Reliable data is not created during calibration—it is revealed by it.

|

|

| High-Accuracy Irradiance Control Sensor | Black Panel Temperature Control System |

A:

The standard xenon lamp lifespan is 1,600 hours. Beyond this, irradiance gradually decreases and may affect test accuracy.

LIB industry recommends timely replacement to ensure reliable results. Proper current control, stable cooling, and clean operating conditions can help optimize usable lamp life, which is already considered in our system design.

A:

Irradiance is controlled by adjusting the lamp operating current, not by changing the lamp itself.

Radiometers monitor specific wavelength bands and feed data back to the controller, allowing closed-loop irradiance regulation.

LIB industry integrates precision sensors and power control to maintain stable, repeatable light exposure.

A:

The lamp generates light, the ignitor provides high-voltage ignition, and the power supply maintains stable operation.

LIB industry designs these components as a fully matched system, ensuring smooth ignition, constant irradiance, and long-term reliability.

A:

Light blackening may be cleaned carefully to extend use, and LIB industry provides maintenance guidance.

However, for accuracy and safety, lamp replacement is recommended once aging becomes significant.

A:

With enhanced configuration, the chamber can reach –70 °C, requiring:

Low-temperature resistant lamp design

Higher refrigeration capacity

Specialized irradiance sensor and black panel system

LIB industry offers customized solutions for extreme temperature light testing.

A:

Black panel temperature is calibrated by qualified third-party labs using ASTM-compliant probes.

Temperature and humidity are verified using a 9-point uniformity method.

Irradiance is calibrated before shipment, ready for immediate use.

Contact LIB industry today to receive a technical proposal tailored to your xenon arc and light fastness testing requirements.

Each solution includes professional pre-sales consultation, on-site installation and commissioning, operator training, a 3-year warranty, and lifelong technical support. With responsive English-speaking service and global spare parts availability, LIB industry ensures reliable operation throughout the entire equipment lifecycle.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia

.jpg)