In environmental reliability testing, temperature and humidity test chambers are widely used to simulate climate conditions such as high temperature, low temperature, high humidity and dryness, and to verify the performance changes of electronic, electrical, material, automotive parts and other products under extreme climate conditions.

To ensure the scientificity and repeatability of the test, the uniformity and fluctuation of temperature and humidity inside the temperature and humidity test chamber are of vital importance.

Temperature/humidity uniformity refers to the maximum difference in temperature and humidity between different positions under the stable operation of the test chamber. That is to say, at the same point in time, whether the environmental conditions among different detection points inside the chamber are consistent.

For example: If the set temperature is 85℃, the measured lowest point is 83℃ and the highest point is 87℃, then the temperature uniformity is ±2℃.

Temperature/humidity fluctuation refers to the range of temperature and humidity fluctuations at the same point within a certain period of time during the stable operation stage of the test chamber. It reflects the ability of environmental stability.

For example: During continuous operation for 30 minutes, the temperature at a certain point fluctuated from 84.8℃ to 85.3℃, with a fluctuation of ±0.5℃.

If the uniformity of temperature and humidity is poor, it indicates that the environmental conditions in which different test samples are located are significantly different, which may easily lead to inconsistent performance evaluations of the products. This is particularly evident for batch testing. Samples from the same batch may perform differently at different aging rates, affecting the judgment.

Some components (such as electrolytic capacitors and photoelectric sensors) are extremely sensitive to temperature and humidity. If the temperature or humidity fluctuates greatly, it may cause abnormal thermal expansion/moisture absorption behavior of the material, misleading the assessment of aging trends.

International/national standards such as IEC 60068-2-78 and GB/T 2423.3 all put forward clear requirements for the uniformity and volatility of temperature and humidity.

When conducting high-temperature and high-humidity coupling tests (such as 85℃/85%RH), any instability in the environment may lead to premature failure of internal components or coatings, making it impossible to accurately assess the actual service life or failure mode.

As a professional brand in the manufacturing of environmental test equipment, LIB has been deeply engaged in temperature and humidity control technology for many years and is committed to providing customers with a test environment of higher precision and higher consistency.

Model | TH-100 | TH-225 | TH-500 | TH-1000 |

Heat load | 1000W | |||

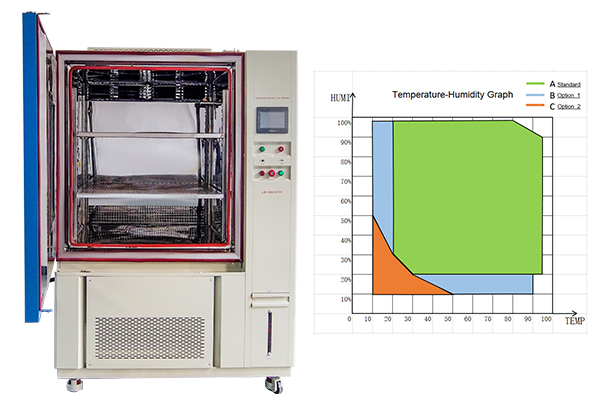

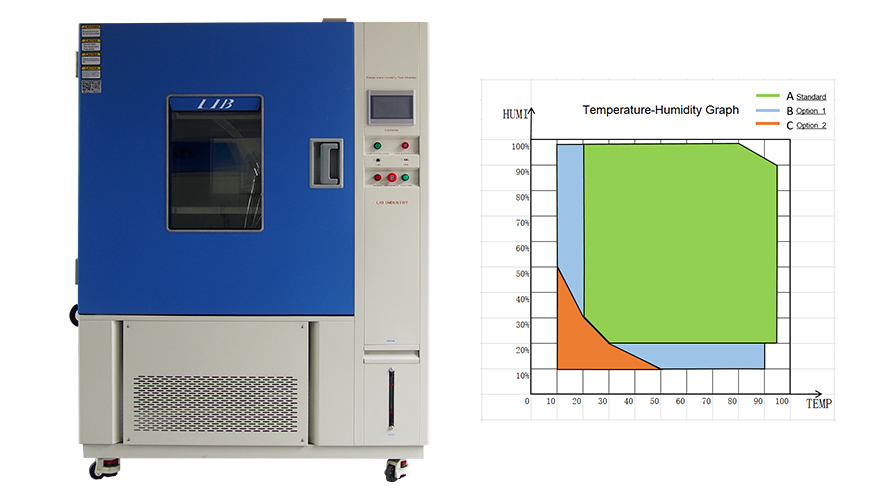

Temperature Range | A : -20℃ ~ +150 ℃ B : -40℃ ~ +150 ℃ C: -70℃ ~ +150 ℃ | |||

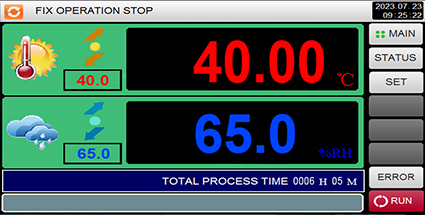

Temperature Fluctuation | ± 0.5 ℃ | |||

Temperature Deviation | ± 2.0 ℃ | |||

Humidity Range | 20% ~ 98% RH | |||

Humidity Deviation | ± 2.5% RH | |||

Cooling Rate | 1 ℃ / min | |||

Heating Rate | 3 ℃ / min | |||

| ||||

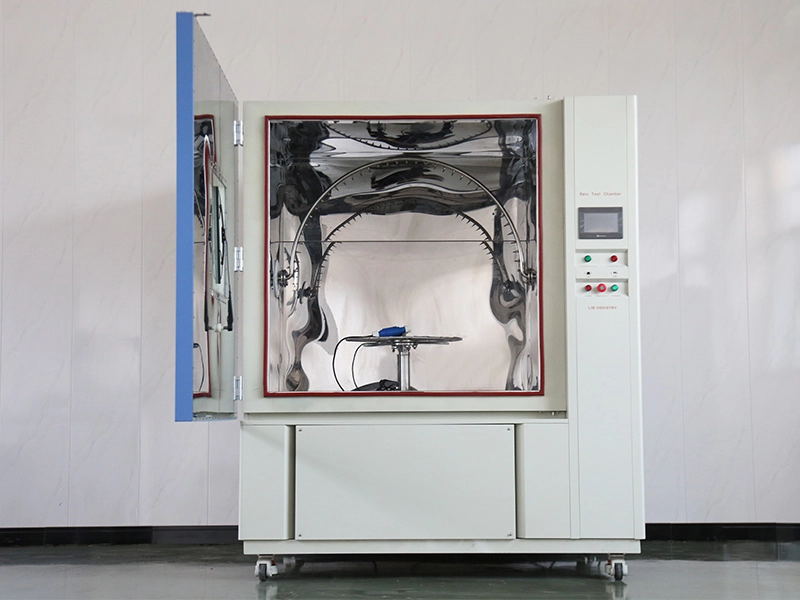

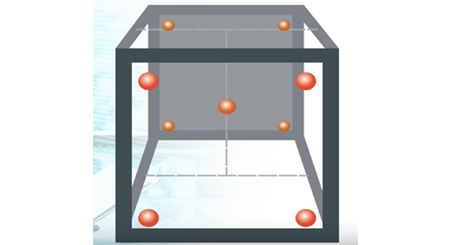

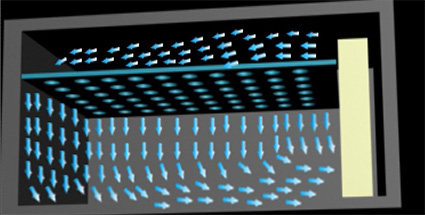

Air circulation system optimization: An automatic wind speed adjustment system is adopted, with horizontal circulation air outlet to achieve rapid and balanced temperature field.

Full enclosure structure insulation design: 100mm polyester ammonia foam reduces heat conduction interference, improves temperature retention and fluctuation control accuracy.

Intelligent control algorithm: PID control system, which can automatically fine-tune the heating/humidification power according to environmental changes to avoid overcharge.

Uniformity reflects spatial consistency, while volatility represents temporal stability. If the two do not meet the standards, even the most perfect testing process will lose its reference value.

The LIB thermal humidity chamber, with its precise control system, balanced airflow structure and intelligent design, is widely used in universities, research institutes, military laboratories and various manufacturing enterprises. Whether you are conducting component aging tests, accelerating life verification of automotive parts, or evaluating the weather resistance of materials, LIB can provide you with high-precision and high-stability temperature and humidity test chamber solutions.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia