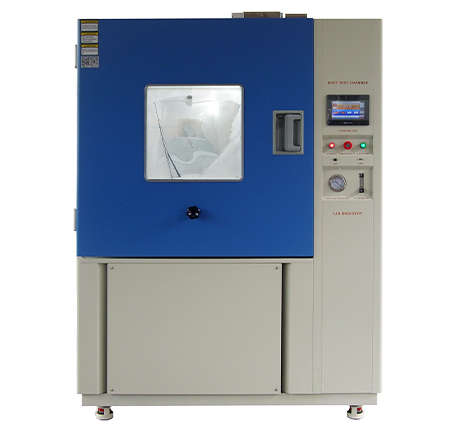

Electronic devices, automotive components, and industrial equipment are constantly exposed to dust and sand particles in real-world environments. The IP5X 6X dust test chamber from LIB Industry simulates these conditions to ensure product reliability and compliance with international protection standards.

Using a high-precision settling dust chamber can help engineers detect vulnerabilities before products reach the market, reducing failures, warranty costs, and maintenance requirements. Regular dust testing also aids in product development by providing actionable data to refine materials, enclosures, and design tolerances.

|

|

IP ratings indicate the level of ingress protection. IP5X (dust protected) allows limited dust ingress but prevents harmful accumulation, whereas IP6X (dust tight) ensures no dust enters the device under test.

Typically, particle size for testing is ≤75 µm, and testing evaluates critical components exposed to harsh environments. Understanding the differences between these ratings allows engineers to select appropriate testing levels based on intended operating conditions, environmental exposure, and product criticality.

The operation of IP5X 6X dust test chambers aligns with international standards such as IEC 60529, ISO 20653. LIB Industry chambers are engineered to meet these regulations, making them suitable for testing automotive sensors, electrical enclosures, military equipment, and consumer electronics.

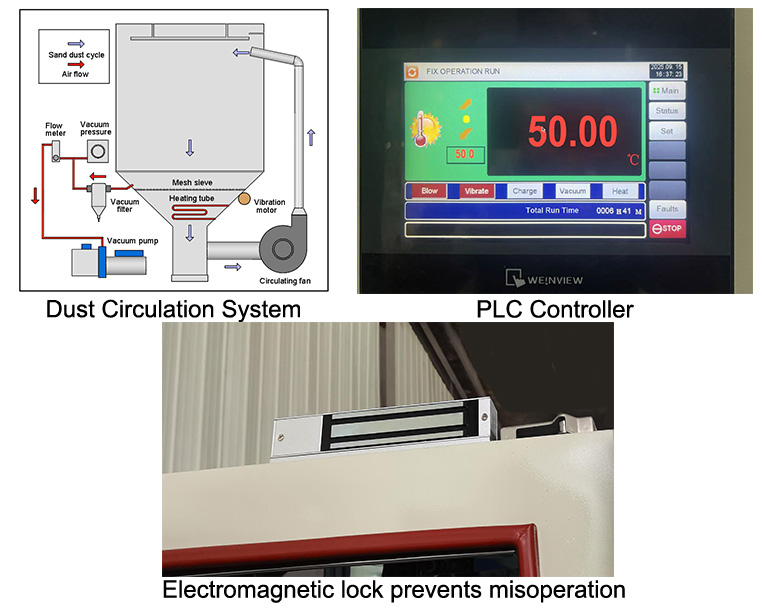

O-type vertical dust circulation system ensures uniform exposure for repeatable results across multiple test samples. The system maintains a consistent wind speed of 1.5–2.5 m/s, allowing particles to settle evenly on all surfaces within the chamber.

Full programmability for multiple cycles and remote monitoring. Users can set up to 50 different test programs, with real-time data logging for airflow, particle density, and test duration.

Prevents dust leakage, maintains controlled particle concentration, and ensures repeatable test conditions. Leakage is typically below 0.5% during standard IP6X tests.

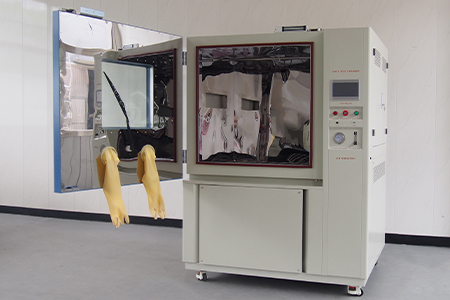

o Door Gloves: Allow adjustment of test samples without opening the chamber, reducing contamination.

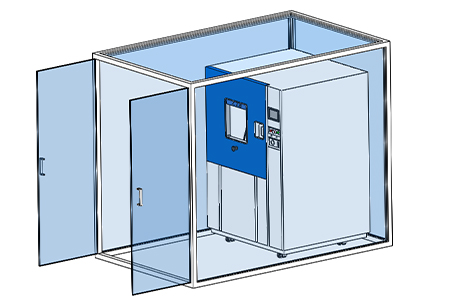

o External Protective Casing: Keeps laboratory clean during testing and provides additional environmental isolation, preventing up to 99% of dust escape.

o Adjustable Dimensions: Accommodates small electronics to large assemblies, from 800L to walk-in types,suitable for automotive lighting, sensor arrays, and industrial enclosures.

|

|

Model | DI-800 | DI-1000 | DI-1500 | DI-2000 |

Useful Volume (L) | 800 | 1000 | 1500 | 2000 |

Temperature Range | Ambient ~ +50℃ | |||

Humidity Range | < 30% RH | |||

Normal Wire Diameter | 50um | |||

Nominal Width of a Gap Between wires | 75um | |||

Fight Time | 0 ~ 99H59M | |||

Blowing Time | 0 ~ 99H59M | |||

Specimen Power Outlet | Dust-proof socket 16A | |||

Controller | Programmable color LCD touch screen controller, Ethernet connection | |||

1. Preparation: Clean the chamber and test samples, ensuring proper sealing and positioning.

2. Dust Loading: Introduce standardized dust particles and evenly distribute via automated circulation (wind speed 1.5–2.5 m/s). Ensure uniform distribution throughout the chamber volume.

3. Testing: Run the test for 2–8 hours, monitoring airflow and dust concentration continuously. Sensors inside the chamber confirm particle density and movement.

4. Observation: Inspect test samples for dust ingress at multiple checkpoints, including connectors, vents, and seams.

5. Data Recording: Capture test parameters, airflow, dust distribution, and results via touchscreen interface, which can generate reports automatically.

IP5X: Allows limited dust ingress; testing uses standard airflow and dust loading.

IP6X: Fully dust tight; includes a vacuum phase (evacuate chamber to -20 kPa ± 2 kPa for 10–15 minutes) to enhance dust penetration simulation. Other steps such as dust loading, testing duration, observation, and data recording remain similar to IP5X.

Q1: What is the difference between IP5X and IP6X tests?

A: IP5X permits limited dust ingress; IP6X is fully dust tight, often requiring a vacuum step to simulate extreme environments.

Q2: How long does each test typically take?

A: Standard test durations range from 2–8 hours, depending on product size, dust type, and complexity.

Q3: What types of dust are used?

A: Fine powders ≤75 µm, including silica sand, talcum powder, or other standardized materials, are used according to IEC and ISO standards.

Q4: Does LIB industry provide calibration and on-site installation?

A: Yes. All chambers are calibrated per ISO 17025, and professional installation, training, and service guidance are provided worldwide.

IP5X 6X dust tests, conducted using LIB Industry’s advanced Sand and Dust Chamber , provide critical insight into a product’s durability against dust ingress.

Call to Action: Contact LIB Industry inquiry@libtestchamber.com today to explore how our IP5X 6X dust test chambers, LIB team will respond with 1~3 hours.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia

_Compliance_Guide_How_LIB_Industry_Stability_Chambers_Accelerate_Pharmaceutical_Registration2_20251230154049.webp)