In today's era of rapid development of science and technology, battery packs are used in a variety of industrial fields such as automobiles, computers, communications, national defense, and new energy markets, especially in the new energy car industry. As a key energy storage unit in these fields, its performance and reliability are crucial. The wide application of batteries requires more reliable quality assurance and safety in use.

Taking lithium batteries as an example, its important role as a new energy power battery energy storage has been successfully verified, and it is a representative of modern high-performance batteries. The continuous expansion of battery capacity and gradually increasing frequency of use are of great concern to battery manufacturers and end users because of their possible failure and potential abnormal hazards. In order to ensure the safe, stable and efficient operation of the battery pack under various environmental conditions, the importance of using the environmental test chamber to test the battery is self-evident.

An environmental chamber is a type of test equipment specially designed to simulate various extreme environmental conditions. It can accurately control temperature, humidity, air pressure and other parameters, and provide a test environment similar to the actual application scenario for the battery pack, which is used to simulate different ambient temperatures and humidity that meet the relevant specifications and standards of IEC62133, UL1642, UN38.3, GB31241, etc. Through the program design, it can carry out tests such as wet heat aging and temperature cycling. A wide range of test parts such as single batteries, battery modules and battery components can be tested in the environmental test chamber; Test its charging, discharging, storage and use performance.

When the environmental chamber is used to test the battery, it mainly accesses the following aspects:

First of all, environmental chamber can perform thermal shock immersion test complying with LV 124. There are two workroom in this chamber, the heat chamber temperature range from ambient to +150℃, the general test requirement is +70℃.the another cool room is filled with 0℃ salt water. The battery goes through cold and heat shocks between the hot room and cold room. A thermal shock immersion test involves quickly moving the battery from a high temperature environment to a low temperature environment, vice versa. And the length of immersion time can be determined according to specific test requirements and standards. During the immersion test, observe whether the battery has abnormal phenomena such as leakage, smoke, fire or explosion. At the same time, record the temperature, time and other relevant data during the test.

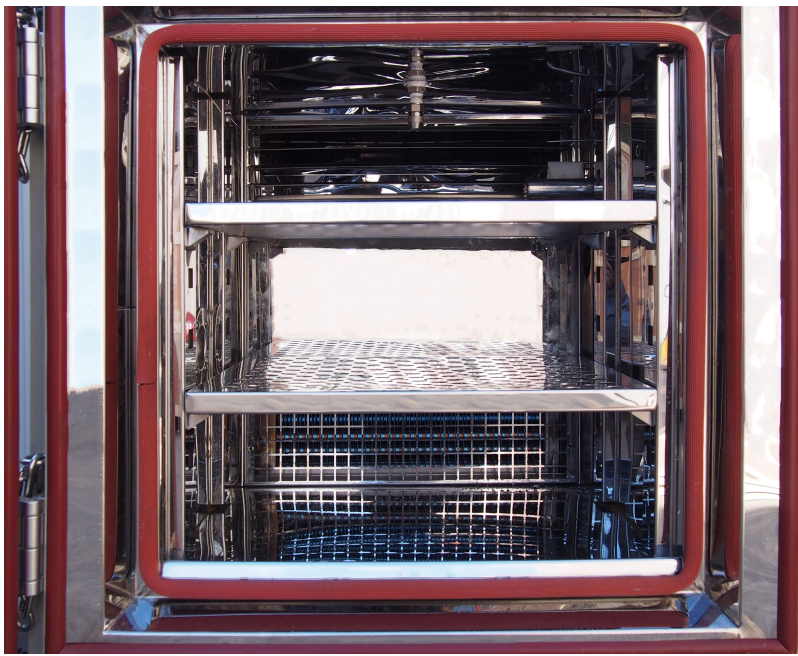

Except thermal shock immersion test, the environmental chamber can carry out temperature humidity test, thermal test, temperature cycling according different test standards. This environmental chamber uses resistance heating, accurate temperature control, good internal temperature uniformity, and small temperature fluctuation. The interior of the test chamber is usually insulated and the control system is precise to ensure that the environmental parameters in the test chamber can be accurately controlled and stable.

Humidity is also a key factor. In a humid environment, the battery pack may face risks such as corrosion and short circuit. The environmental test chamber can be set to different humidity levels to test the moisture resistance and long-term stability of the battery pack.

The environmental chamber can also simulate other environmental factors such as pressure changes, vibration and shock. For example, at high altitudes, low air pressure can have an impact on the battery pack, and potential problems can be identified and addressed in advance by conducting the corresponding air pressure test in the environmental test chamber. Simulate the vibration and turbulence during actual use and transportation to evaluate the integrity of the battery structure and the stability of the electrical performance.

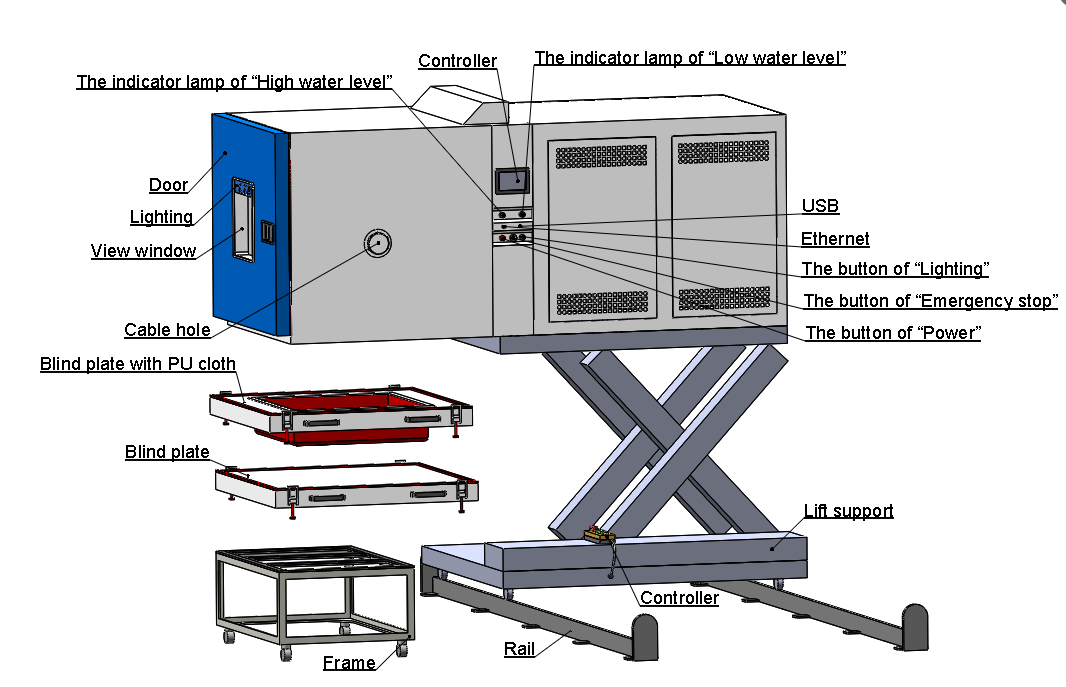

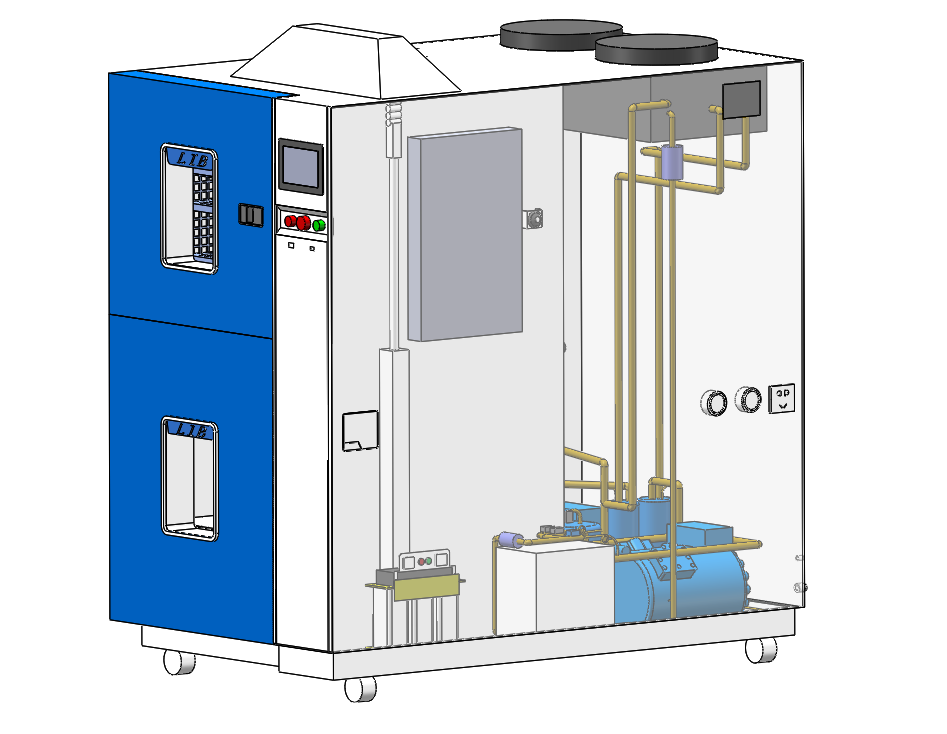

The test chamber is composed of freezing system, heating system, control system, internal circulation system, explosion-proof system, exhaust system and other parts. The chamber is designed in one chamber. The functions of high temperature, humidity and low temperature can be completed in the test chamber at one time.

One thing to note is that the battery may explode during temperature tests or other tests, and the environmental test chamber has a complete safety design to avoid secondary damage. We strengthen the chamber structure to ensure that the test box itself has sufficient strength and tightness to withstand possible explosion, Plus pressure relief design to avoid more serious damage caused by pressure accumulation. In the workroom,it is equipped smog monitoring sensors and take ventilation and other measures.There are spray nozzles at the top of the workroom, so as to quickly extinguish fires in emergency situations. The operator can observe the battery detection through the observation window.

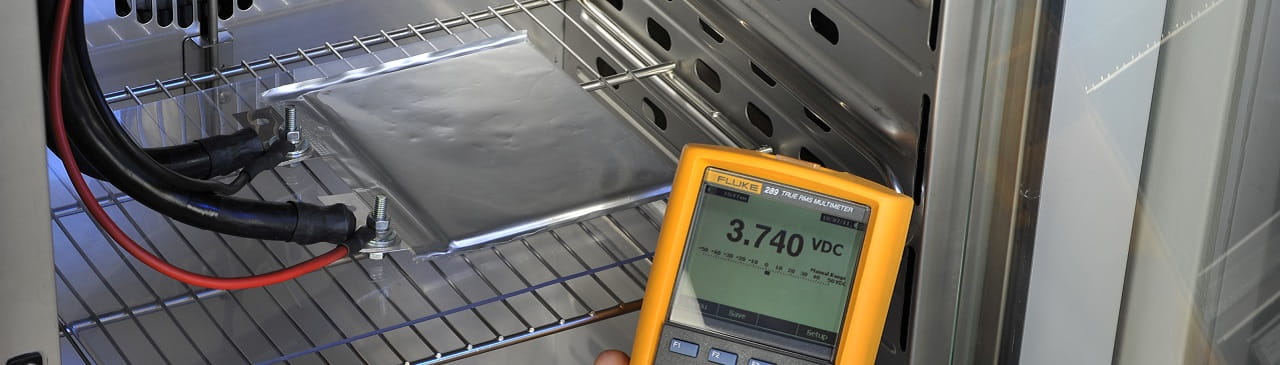

The test chamber is equipped with cable holes, which can power the battery, test the performance of the battery under power, and obtain the most real experimental data.

If you need to carry out special tests on the battery, such as water immersion oil test, etc., you can also customize the environmental test chamber to meet the test requirements.

In short, the environmental test chamber for testing the battery pack is an important tool to ensure the quality and reliability of the battery pack. It provides us with a reliable means to evaluate the performance of battery packs in a variety of complex environments, and lays a solid foundation for promoting the progress of battery technology and application expansion. With the continuous development of battery technology and the continuous expansion of application fields, environmental test chambers will continue to play a key role in ensuring the safe and efficient operation of battery packs.

The interior of the test chamber is usually insulated and a sophisticated control system is used to ensure that the environmental parameters in the test chamber can be accurately controlled and stable. At the same time, the test chamber is also equipped with a variety of sensors and measuring instruments for monitoring and recording battery performance data.

The above is about the environmental chamber for battery testing some of the introduction, if you are interested, need more information and specifications, please leave your contact information and test requirements, our team will soon contact you and give professional solutions. You can also click https://www.libtest.com/products/temperature-and-humidity-chamber/ to know the product information of different models.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia