The accelerated weather tester, through the combined effect of multiple environmental factors such as ultraviolet light irradiation, temperature and humidity cycling, and rain exposure, can assess the weather resistance and service life of materials in a short period of time.

To ensure the scientific accuracy of the test results, relevant test standards are widely adopted in the industry for guidance and regulation.The following are some common standards for accelerated weather tester .

Using xenon arc lamps to simulate the natural solar spectrum has a wider range of applications.

Spectral range: 300nm to 400nm

Light intensity: 550 W/m²

Blackboard temperature: adjustable from 40°C to 65°C

Humidity control: Simulation of wet heat cycle and rain spray

Cycle scheme: Typically 102 minutes of light exposure + 18 minutes of spraying or condensation

Light source: Xenon arc lamp or fluorescent lamp

Blackboard temperature: 45°C to 65°C

Humidity: In combination with condensation moistening or spraying water

Cycle: Different light and moisture cycles can be set according to the material properties

For plastic parts in the automotive industry, the standard requirements are relatively strict:

Xenon arc light spectra simulate the climate throughout the day

Blackboard temperature: 55°C

Rain simulation: Spray angle 45°, nozzle diameter approximately 0.5mm

Cycle time: Typical 48-hour cycle

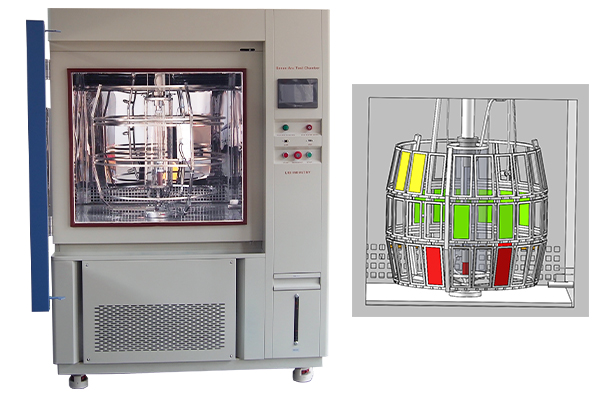

LIB xenon accelerated weather tester launched is widely used in multiple industries such as automobiles, plastics, coatings, and building materials, and fully complies with international test standards such as ASTM G155, ISO 4892-2, and SAE J2527.

Model | XL-S-750 |

Internal Dimension (mm) | 950*950*850 mm |

Overall Dimension (mm) | 1400*1400*1950 mm |

Specimen Holder Size(mm) | 95*200 |

Specimen Capacity | 42pcs |

Chamber Type | Rotating Holder |

Irradiation Source | 1 piece of 4500w water-cooled xenon arc lamp |

Irradiance Range | 35~150 W/㎡ |

Bandwidth Measurement | 300nm~400nm (340nm or 420nm) |

Chamber Temperature Range | Ambient ~ 100 ℃ ±2℃ |

Black Panel Temperature | BPT 35 ~ 85 ℃ ±2℃ |

Humidity Range | 50% ~ 98% RH |

Humidity Deviation | ± 5% RH |

Water Spray Cycle | 1~9999H59M (Adjustable) |

| |

High-performance xenon lamp light source: 4.5kW water-cooled xenon lamps, with a spectral range covering 300nm -400nm, the energy of the light source remains stable for a long time and its lifespan can reach 1,600 hours.Equipped with a variety of filters,adjustable range is 35~150 W/m², with automatic irradiance monitoring.

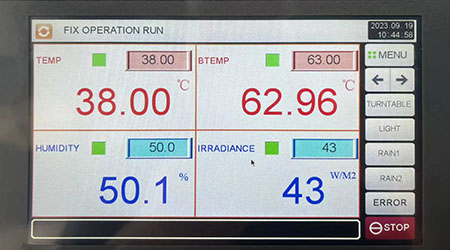

Temperature and humidity control : The blackboard temperature (BPT) can be adjusted from 35℃to 85°C, and the humidity can be controlled within 50% to 95%RH.

Intelligent control: Equipped with a PLC touchable controller, users can customize the test program, and it also has the functions of historical data query and USB export.

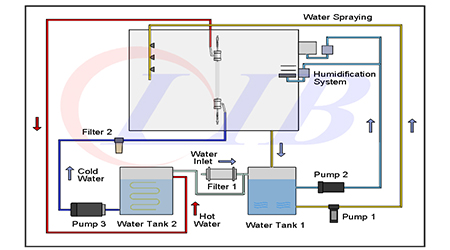

Water spray system: There are nozzles on each rotating frame, and there are return water outlets inside the working chamber. The water is reused after passing through an automatic filtration system.

The accelerated climate test instrument not only relies on the guidance of standards, but also attaches great importance to the matching of actual test conditions with product requirements. For example, the automotive industry has very strict requirements for the light resistance and heat resistance of plastic parts, and tests are usually conducted in combination with ASTM G155 and SAE J2527 standards. Building materials may be more inclined to the UV-wet heat cycle of ASTM G154 or ISO 4892.

By rationally choosing standards and parameters, enterprises can detect in advance problems such as cracking, discoloration and embrittlement that may occur during the use of materials, reduce after-sales risks and improve product quality.

If you are looking for a high-performance xenon test chamber, contact LIB to get a professional accelerated weather tester solution.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia