Why Perform Low-Temperature Xenon Testing?

Unlike standard xenon arc chambers limited to ambient to 100 °C, low-temperature xenon testing reveals how materials respond to extreme cold while under solar radiation. Many polymers, coatings, and adhesives become brittle below freezing, and when combined with UV stress, they may crack, peel, or lose adhesion—behaviors invisible in conventional tests.

This climate solar light chamber is essential for:

Solar panels and photovoltaic coatings, which face sub-zero winters and high solar irradiation.

Automotive exterior coatings, vulnerable to frost and UV-induced cracking.

Outdoor polymers and composites, where low-temperature embrittlement plus UV aging can lead to early failure.

By simulating subzero winter conditions under intense xenon light, manufacturers gain predictive data on material durability, helping reduce field failures, extend product lifespan, and meet stricter quality standards.

Key Advantages of Climatic Chambers for Solar Light Tests

1. High-Precision Solar Simulation

Full-spectrum xenon lamps deliver uniform irradiance ±5 % with intensity up to 150 W/m², accurately replicating sunlight for accelerated aging. Lamp output remains stable over long-duration tests for reproducible and precise results.

2. Broad Environmental Range

Temperature range of –40 °C to +100 °C with ±0.5 °C stability and 20–98 % RH humidity control allows combined UV and environmental stress testing. Low-temperature capability enhances testing scenarios while preserving xenon lamp performance.

3. Long-Life Xenon Lamps & Energy Efficiency

Optimized lamp cooling and dual-stage refrigeration ensure continuous operation, extending xenon lamp life to ≥1,600 h. Energy consumption is reduced by up to 15 %, while maintaining stable UV intensity and climate solar light chamber conditions throughout extended cycles.

4. Intelligent Control & Safety

Programmable PLC touchscreen controller supports multi-step cycles with adjustable UV intensity, temperature ramps, humidity variation, and water spray. Safety features include overheat, overcurrent, lamp cooling monitoring, and anti-freeze protection for reliable operation of both samples and equipment.

5. Condensation / Nighttime Humidity Simulation

The climate solar light chamber can simulate nighttime condensation and high-humidity environments as part of cyclic UV testing. Humidity ramps up to 95 % RH at low temperatures, reproducing morning dew or cold condensation scenarios.

Specifications of Climatic Chambers for Solar Light Tests

Name | Xenon Arc Lamp Light Fastness Aging Device |

Model | XL-S-750 |

Internal Dimension (mm) | 950*950*850 mm |

Overall Dimension (mm) | 1400*1400*1950 mm |

Specimen Holder Size(mm) | 95*200 |

Specimen Capacity | 42pcs |

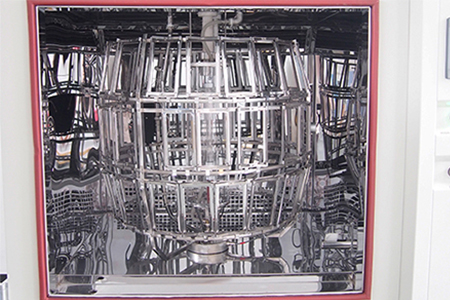

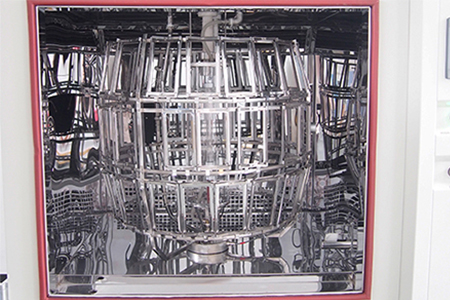

Chamber Type | Rotating Holder |

Irradiation Source | 1 piece of 4500w water-cooled xenon arc lamp |

Irradiance Range | 35~150 W/㎡ |

Bandwidth Measurement | 300nm~400nm (340nm or 420nm) |

Chamber Temperature Range | Ambient ~ 100 ℃ ±2℃ |

Black Panel Temperature | BPT 35 ~ 85 ℃ ±2℃ |

Humidity Range | 50% ~ 98% RH |

Humidity Deviation | ± 5% RH |

Water Spray Cycle | 1~9999H59M (Adjustable) |

Controller | Programmable color LCD touch screen controller |

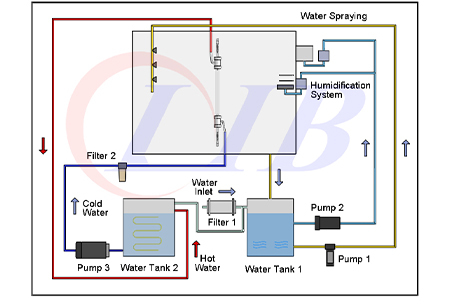

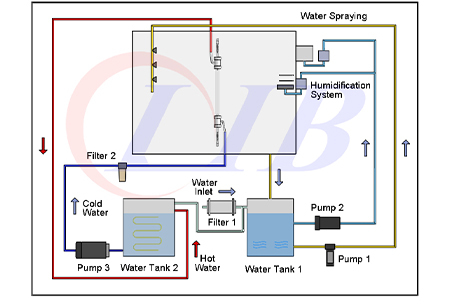

Water supply system | Automatic water supply, Water purification system |

Radiometer | UV Radiometer, Tolerance: ±5% |

Cooling System | Mechanical compression refrigeration system |

Distinctive Details of LIB Industry Climatic Chambers for Solar Light Tests

High-Performance Xenon Lamps | 4500 W/6500 W Water-cooled xenon lamps deliver uniform irradiance and adjustable intensity 35–150 W/m² for accurate solar simulation,with average lifetime of 1,600 h. Featuring outer borosilicate filters with Daylight, Window Glass, and Extended UV options. Optimized cooling ensures stable output.

|

|

Versatile Sample Holders | The climatic chambers for solar light tests supports 3 layers rotating sample holders and flat sample shelves for flexible placement while ensuring uniform UV exposure. Load capacity ranges from 50 kg per shelf, and custom holders can be designed for irregular-shaped or oversized samples.

|

|

Intelligent PLC Controller | A touchscreen PLC controller manages multi-step cycles, including UV irradiation, temperature, humidity variation, water spray. The system supports UV cycle durations from 1 min to 999 h, and precise temperature control and humidity control, ensuring highly reproducible results.

|  |

Black Panel & Reference Irradiance Calibration | A black standard panel with integrated thermocouples to monitor absorbed energy, coupled with a high-precision radiometer (accuracy ±5 %), this enables in-situ calibration without interrupting the test cycle. |

|

Water Circulation & Condensation System | An independent water circulation loop supports cyclic condensation and humidity control up to 98 % RH. Automatic drainage prevents overaccumulation. This system replicates morning dew or night condensation scenarios critical for outdoor durability testing of coatings and polymers.

|

|

Accelerate your testing programs with equipment backed by dependable service and industry-leading support.

LIB industry ensures:

Rapid production and 7~15 working days delivery timelines

Dedicated after-sales engineers for remote or on-site assistance

Comprehensive 3 year warranty with guaranteed spare-part availability

Flexible customization options for lamp, filters, airflow, and test environments

Reach out to LIB industry now to obtain full specifications, quotation, and a personalized Climatic Chambers for Solar Light Tests configuration for your application.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia