Imagine an electronic control unit installed in a vehicle that faces freezing nights and scorching daytime temperatures every single day. Over time, these repeated thermal swings generate mechanical stress that static temperature tests cannot reveal. Components may appear intact during initial inspection, but subtle fatigue accumulates silently—eventually causing premature failures in the field.

Why do some products pass early testing yet fail during real-world operation? Often, the issue isn’t the test plan itself—it’s whether the testing environment realistically simulates the stresses products will encounter. Professional thermal cycling testing is indispensable for uncovering these hidden vulnerabilities.

Thermal cycling tests expose products to alternating high and low temperatures to replicate real-world operating conditions, revealing issues such as:

Material mismatch leading to mechanical stress

Solder joint fatigue in electronics

Adhesive and seal degradation

Structural deformation in assemblies

Industries relying on thermal cycling tests include:

Electronics manufacturing (PCBA, sensors, ICs)

Automotive components (ECUs, battery modules)

Aerospace systems (control units, avionics)

Energy storage and industrial equipment

In all these applications, the accuracy, stability, and repeatability of the test chamber are as critical as the test profile itself. Without a reliable system, even the most carefully designed test can produce misleading results.

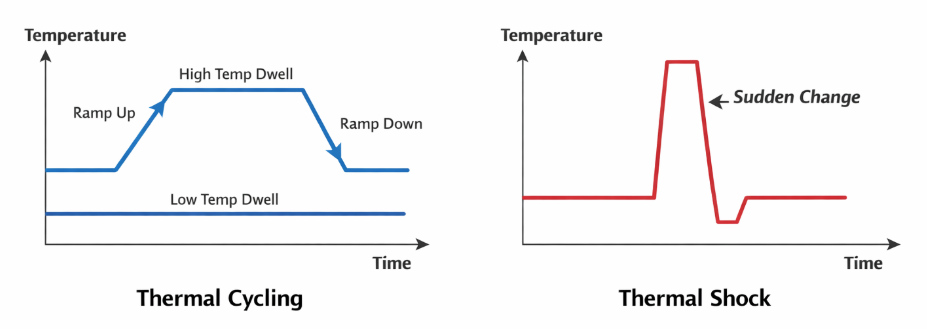

A thermal cycling test repeatedly exposes a product to high and low temperatures over defined cycles. Each cycle typically includes:

Ramp-up to the high temperature

Dwell at high temperature

Ramp-down to low temperature

Dwell at low temperature

The purpose is to evaluate how materials and assemblies respond to repeated thermal expansion and contraction. Differential expansion between materials creates stress at interfaces such as solder joints, adhesives, seals, and fasteners. Over many cycles, this stress can accumulate and cause fatigue-related failures.

Although often mentioned together, these two tests target different objectives:

Test Type | Temperature Transition | Focus | Typical Applications |

Thermal Cycling | Controlled gradual change | Fatigue accumulation | Electronics, automotive, batteries |

Thermal Shock | Near-instant temperature change | Immediate failures | Semiconductors, solder joints, high-reliability electronics |

Thermal cycling emphasizes long-term durability under gradual environmental changes, whereas thermal shock identifies sudden weaknesses under extreme stress. Many manufacturers use both in combination to obtain a complete reliability profile.

Thermal cycling tests are typically performed in accordance with recognized standards:

IEC 60068 – Environmental testing for electronic equipment

MIL-STD-810 – Military environmental test methods

JEDEC JESD22 – Semiconductor reliability

ISO 16750 – Road vehicles

Key parameters across these standards include:

Standard | Temperature Range | Ramp Rate | Dwell Time | Typical Cycles |

IEC 60068 | –40°C to +125°C | 5–10°C/min | 10–30 min | 500–1000 |

MIL-STD-810 | –55°C to +125°C | 10–15°C/min | 15–30 min | 500–1500 |

JEDEC JESD22 | –65°C to +150°C | 5–20°C/min | 10–60 min | 1000–2000 |

Meeting these specifications requires chambers capable of precise temperature control, rapid ramp rates, and long-term repeatability.

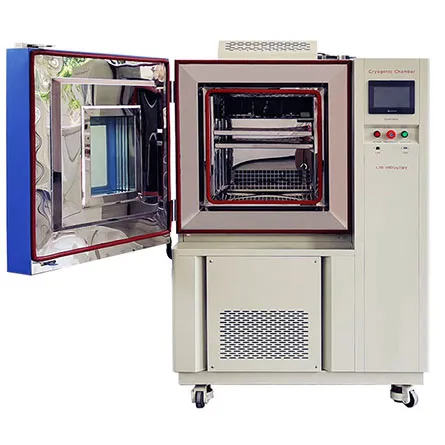

Rapid temperature change test chambers are essential for performing reliable thermal cycling tests. LIB industry’s Thermal Cycling Chamber provide the precise control, speed, and stability necessary for demanding applications.

Key Capabilities of LIB Industry Chambers:

Temperature Range: –70°C to +150°C

Ramp Rates: 5 / 10 / 15 / 20°C/min, fully customizable

Continuous Cycling: 500–2000 cycles without performance drift

Temperature Uniformity: ±1°C

Applications: Automotive ECUs, battery modules, electronic sensors, aerospace electronics

Highlights of LIB Industry Chambers:

Accelerated fatigue testing simulates real-world thermal stresses

Maintains uniform temperature across the chamber during extended sequences

Customizable chamber size for small or large test assemblies

Model | TR5-100 | TR5-225 | TR5-500 | TR5-800 | TR5-1000 |

Interior Volume | 100L | 225L | 500L | 800L | 1000L |

Heat load | 1000W | ||||

Temperature Range | A : -20℃ ~ +150 ℃ B : -40℃ ~ +150 ℃ C: -70℃ ~ +150 ℃ | ||||

Temperature Fluctuation | ± 0.5 ℃ | ||||

Temperature Deviation | ± 2.0 ℃ | ||||

Cooling Rate | 5 ℃ /10 ℃/ 15℃/ 20℃(customized)/ min | ||||

Heating Rate | 5 ℃ /10 ℃/ 15℃/ 20℃(customized)/ min | ||||

Controller | Programmable color LCD touch screen controller, Multi-language interface, Ethernet , USB | ||||

Cooling System | Mechanical compression refrigeration system,environmentally friendly refrigerant | ||||

| |||||

Scenario Example:

A leading automotive supplier needed to simulate a full year of ECU operation in a compressed timeframe. Using LIB industry Temperature Cycle Chamber, the team completed 1000 cycles in less than a month, identifying potential solder joint weaknesses before they reached the field.

Thermal shock chambers are designed for extreme stress testing. LIB industry thermal shock chambers include the 2-zone and the 3-zone thermal shock chambers for rapid hot-cold transitions with high repeatability.

Key Capabilities of LIB Industry Thermal Shock Chambers:

Temperature Range: –70°C to +220°C

Transition Time: Near-instant exposure between hot and cold zones

Repeatability: Consistent across hundreds of cycles

Applications: Semiconductors, solder joints, high-reliability electronics

Highlights:

Detects immediate failures invisible under gradual thermal cycling

Supports high-reliability testing in aerospace, automotive, and industrial electronics

Can be integrated with LIB thermal cycling chambers for comprehensive reliability programs

Model | TS-162 | TS-340 | TS-500 | TS-1000 | |

Interior Volume (mm) | 22L | 72L | 211L | 505L | |

Loading Capacity | 20kg | 30kg | 50kg | 60kg | |

Pre-heat Room | Upper limit Temperature | +220℃ | |||

Heating Time | Ambient ~ + 200℃, within 30 minutes | ||||

Pre-cool Room | Lower limit Temperature | -75℃ | |||

Cooling time | Ambient ~ -70℃, within 30 minutes | ||||

Test Room | High Temperature Exposure Range | Ambient +20 ~ +200°C | |||

Low temperature Exposure Range | –65 ~ -5°C | ||||

Temperature Fluctuation | ≤±0.5℃ | ||||

Temperature Deviation | ≤±3 ℃ | ||||

Temperature Recovery Time | Within 5 minutes | ||||

Interior Material | SUS304 stainless steel | ||||

| Standard Configuration | 2 shelves | ||||

| |||||

Scenario Example:

A semiconductor manufacturer simulated extreme on/off cycling. LIB industry thermal shock chambers revealed micro-cracks in packaging that would have caused early field failures, preventing costly recalls.

The reliability of thermal cycling tests depends not only on the test profile but also on the chamber itself. LIB industry chambers ensure accuracy, stability, and repeatability for every cycle.

| Capability | Ordinary Chambers | LIB Industry Chambers |

|---|---|---|

| Temperature Uniformity | ±5°C | ±1°C |

| Ramp Rate Control | Limited, fluctuates | 5–20°C/min precise, repeatable |

| Long-Term Cycle Reliability | Performance drifts over time | Stable across hundreds/thousands of cycles |

| Extreme Stress Exposure | Slow transitions | Near-instant hot-cold transfer |

| Customization | Limited | Fully adaptable to chamber volume, standards, cycles |

Key Advantages of LIB Industry Chambers:

Wide Temperature Range: Maintains ±1°C uniformity from –70°C to +150°C

Fast and Controlled Ramp Rates: Up to 20°C/min for realistic thermal fatigue simulation

Extreme Thermal Stress: Detects weaknesses invisible to gradual cycling

Long-Term Reliability: Consistent performance across extended testing

Repeatability: Stable thermal profiles for design validation, production qualification, and certifications

Scenario Example:

An electronics manufacturer used LIB industry rapid temperature change chambers to test new battery modules. Hundreds of cycles revealed a potential connector weakness early, preventing large-scale production issues.

Choosing the right chamber is critical. LIB industry provides both solutions with advanced capabilities:

Thermal Cycling Chamber (LIB industry): Gradual transitions, fatigue analysis, long-term reliability

Thermal Shock Chamber (LIB industry): Instant transitions, immediate failure detection

Optimal Strategy: Many manufacturers combine both LIB industry chambers for a full reliability assessment, ensuring products withstand both long-term environmental stresses and extreme thermal shocks

Why LIB Industry Stands Out:

Proven high-speed and high-precision thermal control

Flexible customization for temperature range, ramp rate, and cycle count

Trusted in automotive, aerospace, electronics, and energy storage sectors

LIB industry provides rapid temperature change chambers and thermal shock chambers that deliver precise, repeatable, and reliable testing solutions. By selecting the right testing strategy and equipment, manufacturers can identify potential failures early, optimize product design, and ensure reliable performance in the field.

Global technical support and spare parts

3-year comprehensive warranty covering core systems

Lifetime technical support provided by senior engineers

Rapid remote diagnostics and response within 1–3 hours

For tailored thermal cycling testing solutions and expert support, LIB industry is ready to assist with your specific application requirements.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia