Modern electronic components, automotive connectors, aerospace materials, and industrial coatings are exposed to increasingly complex corrosive environments. Urban pollution, industrial emissions, and mixed chemical atmospheres mean that real-world corrosion is rarely caused by a single gas acting alone.

However, many laboratories still rely on single gas corrosion tests to evaluate material durability. While these tests remain useful for basic research, they often fail to replicate actual service conditions. As a result, products that pass laboratory testing may still experience premature failure in the field.

International standards are already responding to this gap. IEC 60068-2-60 and IEC 60068-2-42 clearly emphasize flowing mixed gas (FMG) testing as a critical method for evaluating corrosion resistance under realistic conditions. For manufacturers targeting global markets, compliance with these standards is no longer optional—it is a prerequisite.

The key challenge for laboratories lies in equipment selection. Choosing a noxious gas test chamber without sufficient expansion capability can limit future testing scope and restrict access to export-oriented projects.

Single gas corrosion tests expose samples to one specific corrosive gas, such as SO₂, under controlled temperature and humidity conditions. This approach is commonly used to simulate:

Acidic industrial atmospheres

Sulfur-rich environments

Controlled laboratory screening tests

Limitations of single gas testing:

Real service environments rarely contain only one corrosive gas.

Corrosion mechanisms are oversimplified.

Test results may underestimate long-term degradation risks.

Most importantly, single gas testing cannot reproduce the synergistic effect between multiple gases. For example, when H₂S and NO₂ coexist, corrosion rates often increase exponentially rather than linearly. This interaction effect cannot be captured by isolated gas exposure.

Multi-gas testing represents the next stage in corrosion simulation accuracy. By exposing samples to controlled mixtures of corrosive gases, laboratories can closely replicate:

Urban atmospheric pollution

Heavy industrial emissions

Coastal environments combining humidity, salt, and chemical gases

This approach enables accelerated aging tests that reveal design weaknesses earlier in the product development cycle, reducing costly redesigns after market release.

| LIB Industry Noxious Gas Test Chamber for Gas Corrosion Tests | |

| SO2 and Humidity Temperature Chamber |

As a result, multi-gas testing has become the benchmark for compliance with IEC 60068 FMG requirements.

The LIB industry GCM Series Noxious Gas Test Chamber is designed specifically to meet the growing demand for accurate, standards-compliant multi-gas corrosion testing.

The GCM Series covers a wide range of testing capacities:

GCM-100 to GCM-1000 standard models

Compact laboratory benchtop systems

Large-capacity chambers for industrial components

Fully customized walk-in noxious gas test chambers for oversized samples

This flexibility allows laboratories to test everything from microelectronic components to large automotive and industrial assemblies.

A single LIB industry noxious gas test chamber can integrate multiple corrosive gases, including:

| Gas | Concentration |

|---|---|

| SO₂ Concentration | 100 ~ 500 ppb ± 20 ppb (Adjustable) |

| H₂S Concentration | 10 ~ 100 ppb ± 20 ppb (Adjustable) |

| NO₂ Concentration | 200 ppb ± 20 ppb (Adjustable) |

| Cl₂ Concentration | 10 ~ 20 ppb ± 5 ppb (Adjustable) |

| NH₃ Concentration | 1,000,000 ~ 2,000,000 ppb (Adjustable) |

Gas configurations can be customized based on applicable standards and customer-specific test profiles.

The GCM Series uses multi-channel electronic mass flow controllers, enabling:

ppb-level gas concentration control

Extremely stable gas mixing ratios

Minimal concentration fluctuation throughout long-duration tests

This level of precision is critical for testing sensitive products such as automotive connectors, PCBs, surface coatings, and electronic enclosures.

A centrifugal airflow circulation system ensures homogeneous gas distribution inside the test space. By eliminating airflow dead zones, the chamber delivers consistent exposure conditions across all sample positions, improving test repeatability and data reliability.

Accurate gas control must be supported by stable temperature and humidity regulation.

Operating range: 15°C to 80°C

Temperature fluctuation: ≤ ±0.5°C

This stability supports long-term corrosion studies and accelerated aging protocols.

Humidity range: 30% to 98% RH

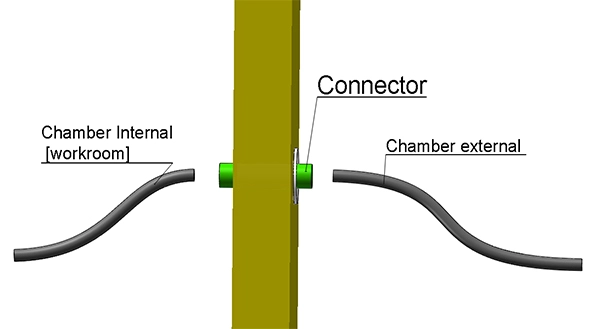

External stainless steel surface evaporation humidifier

The isolated humidification system prevents interaction between moisture generation and gas concentration, ensuring that humidity control does not compromise gas accuracy—an essential requirement for mixed gas corrosion testing.

The LIB industry GCM Series features an advanced PLC-based control platform with:

Full-color LCD touchscreen

Intuitive, operator-friendly interface

Multi-program storage and execution

Users can create dynamic test profiles with time-based variations in temperature, humidity, and gas concentration to simulate:

Day–night environmental changes

Pollution fluctuation cycles

Complex real-world exposure conditions

Ethernet connectivity and PC link functionality enable remote monitoring, data logging, and seamless integration into digital laboratory management systems.

Safety is a critical factor in noxious gas testing. The GCM Series incorporates multiple protection layers:

Corrosion-Resistant Construction

SUS316 stainless steel interior combined with reinforced fiberglass structures and special anti-corrosion exterior coatings.

Exhaust Gas Treatment System

Integrated high-efficiency gas filtration ensures exhaust emissions meet environmental protection requirements.

Electrical and Thermal Protection

Over-temperature, over-pressure, dry-heating, and leakage protection systems.

Interlock Safety Design

Electromagnetic door locks prevent accidental exposure during operation.

System Monitoring and Alarms

Continuous system diagnostics with automatic shutdown in abnormal conditions.

|

|

A noxious gas test chamber is a broad term describing equipment designed to expose materials or components to corrosive or harmful gases under controlled conditions. An FMG test chamber is a specific type of noxious gas test chamber capable of simultaneously controlling multiple gases at precise concentrations and flow rates, as required by standards such as IEC 60068-2-60. In practice, FMG capability represents a higher level of simulation accuracy and compliance.

In most cases, upgrading a single gas system to true multi-gas FMG performance is technically difficult and cost-inefficient. Limitations in gas routing, flow control accuracy, material compatibility, and safety systems often make retrofitting impractical. Selecting a multi-gas-capable noxious gas test chamber from the outset helps laboratories avoid costly reinvestment as testing requirements evolve.

LIB industry integrates safety at multiple levels, including corrosion-resistant construction materials, exhaust gas treatment systems, electromagnetic door interlocks, and continuous system monitoring with automatic shutdown. These measures ensure safe operation even during long-term exposure to highly corrosive gas mixtures.

Yes. LIB industry designs each GCM Series configuration based on applicable standards, gas combinations, concentration ranges, sample size, and future expansion needs. Customized solutions—including walk-in chambers and special gas profiles—are available to support both current testing and long-term laboratory development.

LIB industry works closely with you to define the correct gas composition and FMG test profiles, match chamber capacity to your current and future samples, and ensure full compliance with IEC 60068-2-60, IEC 60068-2-42, and customer-specific specifications.

To protect your long-term investment, LIB industry backs every noxious gas test chamber with a 3-year warranty and lifelong technical support. Our 24/7 English-speaking service team, globally stocked spare parts, and professional commissioning support help ensure stable operation and minimal downtime throughout your qualification projects.

Contact LIB industry today inquiry@libtestchamber.com to configure a noxious gas test chamber solution tailored to your application and compliance goals.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia