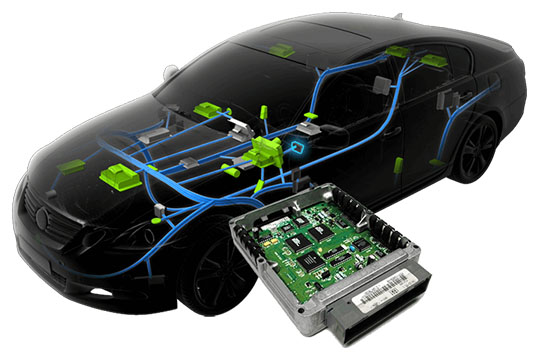

When an electronic control module inside a car suddenly fails on a scorching summer day or a freezing winter morning, the root cause often lies in one thing—thermal stress. Components expand and contract at different rates, solder joints weaken, and plastics become brittle. These invisible battles inside products are why temperature cycle test equipment has become indispensable in modern reliability engineering.

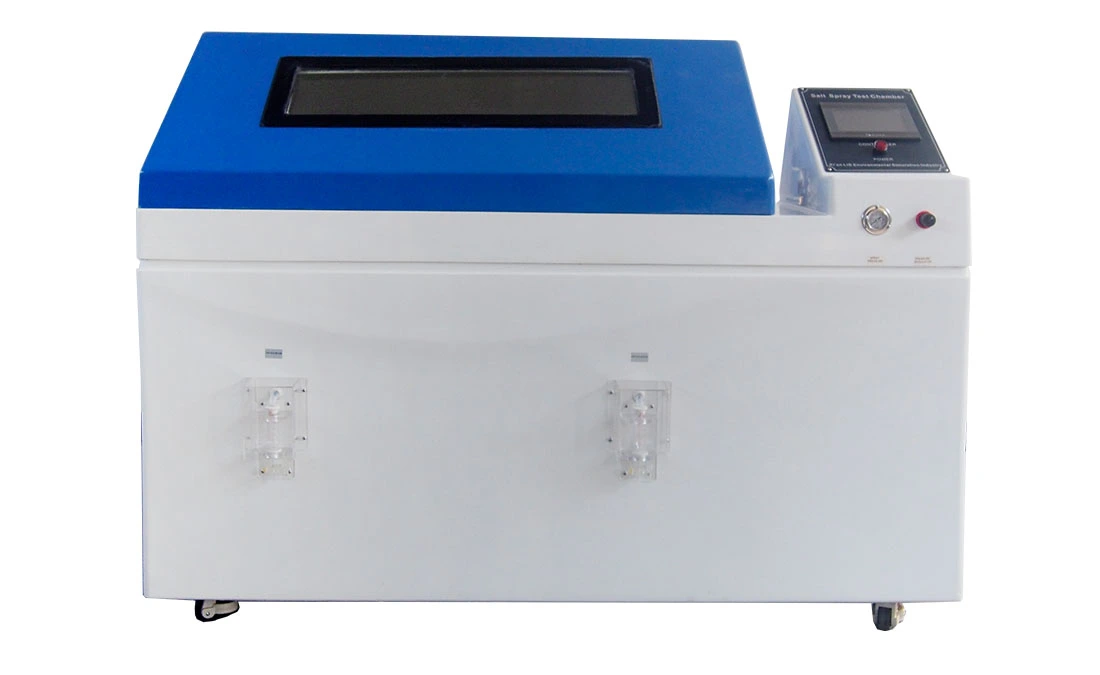

Instead of waiting years for field data, manufacturers now simulate decades of real-world use in a matter of weeks. With temperature cycle test equipment by LIB, engineers can push products to their limits, expose hidden weaknesses, and verify compliance with global standards—all before the first customer ever turns the ignition key.

Temperature cycling exposes a product to alternating high and low temperature extremes. This repeated expansion and contraction accelerates aging and highlights weaknesses in design or material selection. Industries such as automotive, aerospace, and consumer electronics rely on this testing to:

- Validate product durability under harsh conditions

- Detect latent manufacturing defects

- Meet international reliability standards (e.g., IEC, JESD22, MIL-STD)

- Reduce warranty claims and field failures

Modern temperature cycle chambers are engineered with several advanced capabilities:

Feature | Purpose |

Wide Temperature Range (-70/ -40/ -20°C to +180°C) | Simulates real-world environments, from arctic cold to engine heat. |

Fast Ramp Rates (up to 5/10/15/20°C/min) | Accelerates stress cycles, reducing test duration. |

Uniform Airflow System | Ensures consistent exposure of all test samples. |

Programmable Controller | Enables complex thermal cycling profiles and data logging. |

Safety & Reliability | Over-temperature protection and stable refrigeration system. |

| |

To illustrate how LIB temperature cycle test equipment are applied, let’s take the example of testing an Automotive Electronic Control Unit (ECU).

Test Objective: Validate solder joint reliability and PCB durability under long-term temperature cycling.

Standards Followed:

- AEC-Q100: Stress test qualification for automotive integrated circuits.

- IEC 60068-2-14: Environmental testing – Thermal shock and cycling.

Test Parameters:

- Temperature range: -40°C to +125°C

- Dwell time: 30 minutes at each extreme

- Ramp rate: 15°C/min

- Total cycles: 1000 cycles

Process:

1. The ECU is mounted on a fixture inside LIB’s temperature cycle chamber.

2. The controller is programmed with the thermal cycle profile.

3. Data logging records temperature uniformity and cycle counts.

4. Post-test analysis inspects solder cracks under a microscope, ensuring compliance with AEC-Q100.

This process allows automotive suppliers to predict field performance without waiting for years of real-world use.

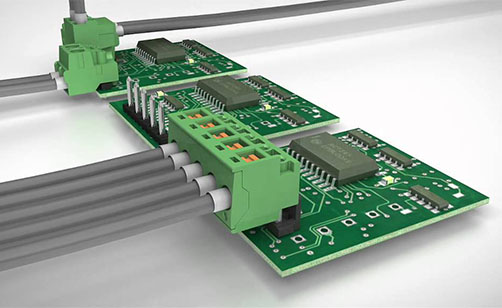

Electronics manufacturers also rely heavily on thermal cycle testing for printed circuit boards and connectors. For instance, consumer smartphones undergo tests ranging from -20°C to +70°C, simulating daily usage in different climates. Failures such as micro-cracks, delamination, or connector loosening can be caught early, preventing mass recalls.

LIB’s temperature cycle chambers, with precise temperature uniformity and long operational stability, support these rigorous testing requirements.

LIB stands out by offering:

- Customization: Non-standard chamber sizes and combined test functions (temperature, humidity, vibration).

- Precision: High accuracy sensors and uniform airflow for consistent results.

- Energy Efficiency: Modern refrigeration systems designed for sustainable operation.

- Global Compliance: Chambers designed to meet IEC, MIL-STD, and automotive AEC standards. Whether for automotive suppliers or electronic device manufacturers, LIB provides a comprehensive testing solution that ensures both compliance and product excellence.

Whether for automotive suppliers or electronic device manufacturers, LIB provides a comprehensive testing solution that ensures both compliance and product excellence.

Reliability is non-negotiable in the automotive and electronics industries. Temperature cycle test equipment plays a pivotal role in exposing weaknesses, ensuring compliance, and delivering durable products to the market. LIB’s temperature cycle test equipment are engineered to replicate the harshest environments, helping manufacturers reduce risks and build trust with their customers.

Ready to enhance your product reliability testing? Explore LIB’s full range of temperature cycle test equipment and contact our team today for a customized solution tailored to your industry needs.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia