Rugged outdoor devices face some of the harshest environmental challenges—from swirling dust storms to prolonged water immersion and extreme temperature variations ranging from -20°C to +60°C. For manufacturers, ensuring product reliability under these conditions is critical.

LIB industry’s IP68 Dust and Water Ingress Chambers provide a controlled, repeatable, and precise testing environment. These IP68 test chambers allow companies to simulate real-world conditions and verify the durability of their outdoor equipment.

|

|

| IP6X Dust Ingress Chambers | IPX8 Water Ingress Chambers |

Understanding the IP rating system is crucial for testing.

IP6X evaluates total protection against dust ingress, ensuring no particles larger than 75 microns penetrate the enclosure. IPX8 measures water ingress protection under continuous immersion, typically up to 3 meters depth for durations of 1–24 hours.

Compliance with these standards is essential not only for product certification but also for consumer confidence. Testing cycles can be programmed to run for up to 72 hours continuously, simulating extended real-world exposure.

LIB industry’s IP6X Dust Test Chambers , a key component of the IP68 Dust and Water Ingress Chambers solution, are engineered for high-precision dust ingress testing of rugged outdoor equipment.

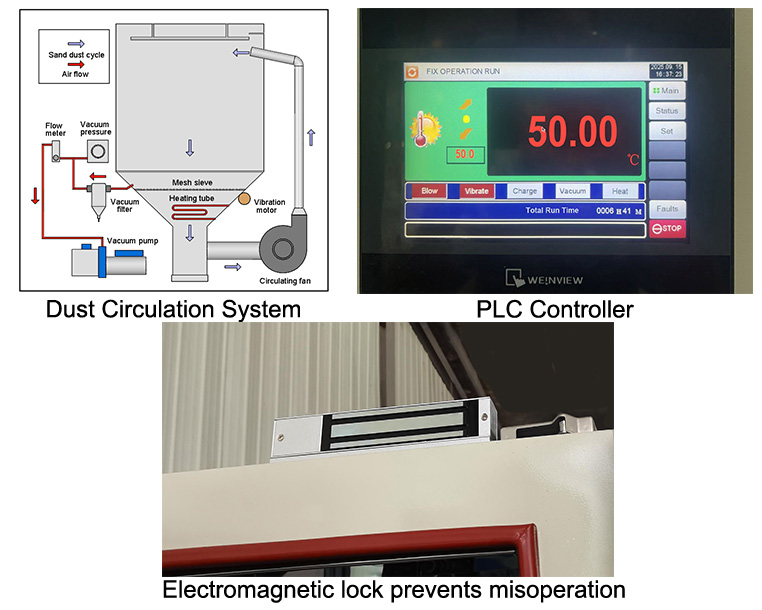

The dust test chamber utilizes high-velocity fans and strategically placed air inlets to ensure uniform distribution of fine particulate matter across all device surfaces. This system simulates real-world dust exposure with controlled dust density, minimizing hotspots and ensuring consistent testing results.

The IP dust chamber features both suspended and flat sample racks, accommodating multiple devices of varying sizes and weights. Each rack is designed for optimal airflow and accessibility.

The control interface enables fully programmable test cycles, including dust density settings, test duration. Real-time monitoring with integrated alarms ensures immediate detection of parameter deviations, enhancing test reliability.

Constructed from 12mm thick safety glass, the observation window with manual wiper provides clear visibility of devices during testing, allowing engineers to monitor performance without opening the door and disrupting the test environment.

The IP6X dust test chamber is equipped with an advanced dust collection and filtration system, maintaining consistent dust concentration while reducing maintenance requirements and prolonging operational life and dust can be reused.

The IPX8 Water Ingress Chambers from LIB industry are designed for rigorous water ingress testing, ensuring outdoor devices can withstand continuous immersion in challenging environments.

The IPX7 X8 is used for water immersion testing of specimen under IPX7 and IPX8 ratings,which simulate water depths of 1-50m with pressure up to 50bar.

Engineers can configure continuous or intermittent immersion cycles, from 1 hour up to 24 hours per cycle. The system supports automated sequencing for long-duration tests, enabling consistent and repeatable results without manual intervention.

The IP68 waterproof test chamber includes automatic water level sensors, emergency shutoff systems, and overflow protection. These features ensure the safety of both the devices and operators during testing, while the observation window allows real-time visual monitoring.

LIB industry IP68 dust and water ingress chambers are widely used for:

- Smartwatches, fitness trackers, and waterproof earbuds

- Outdoor cameras and drones

- Industrial measurement instruments

- Military and protective equipment

Each IP68 test chamber can simulate dust exposure and water immersion for extended periods, ensuring devices perform reliably outside the lab. They provide comprehensive monitoring, including temperature, humidity, dust density, and immersion depth.

· Sample Preparation: Proper device placement ensures consistent exposure.

· Test Cycle Planning: Match cycles to real-world conditions.

· Maintenance and Calibration: Sensors calibrated every 3 months.

· Data Analysis and Reporting: Record temperature, humidity, dust density, and immersion depth. Keywords: IP6X IPX8 chamber operation, dust and water ingress testing tips.

1. Maximum dust density for IP6X testing?

LIB industry chambers can safely operate up to 200g/m³, ensuring accurate and repeatable dust ingress testing across multiple devices.

2. Maximum water depth and immersion time for IPX8 testing?

IPX8 Water Ingress Chambers from LIB industry can submerge devices up to 3 meters for up to 24 hours, simulating rigorous real-world immersion conditions for outdoor equipment.

3. Can multiple IP tets devices be tested simultaneously?

Yes, both IP6X and IPX8 chambers support testing of up to 20 devices at a time, allowing efficient batch testing without compromising test accuracy.

4. Are custom dust and water ingress chamber sizes available?

LIB industry offers customizable chamber dimensions, accommodating devices up to 1500mm in height and 1200mm in width to meet diverse product testing needs.

5. Calibration frequency?

Regular calibration every 3 months is recommended to maintain precise performance and reliable data for both IP6X and IPX8 testing cycles.

LIB industry provides:

- Customizable Sizes and Multi-Functional Testing

- Intelligent Control Systems with programmable cycles

- Global Reliability and Support (3-year warranty and lifetime service)

- Proven Industry Success with top manufacturers

LIB industry’s IP6X Dust Ingress Chambers and IPX8 Water Ingress Chambers offer precise, reliable, and repeatable testing for harsh conditions. Contact LIB industry today inquiry@libtestchamber.com to explore custom solutions and elevate your product reliability,the quote and specs will be sent with 1~3 hours.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia