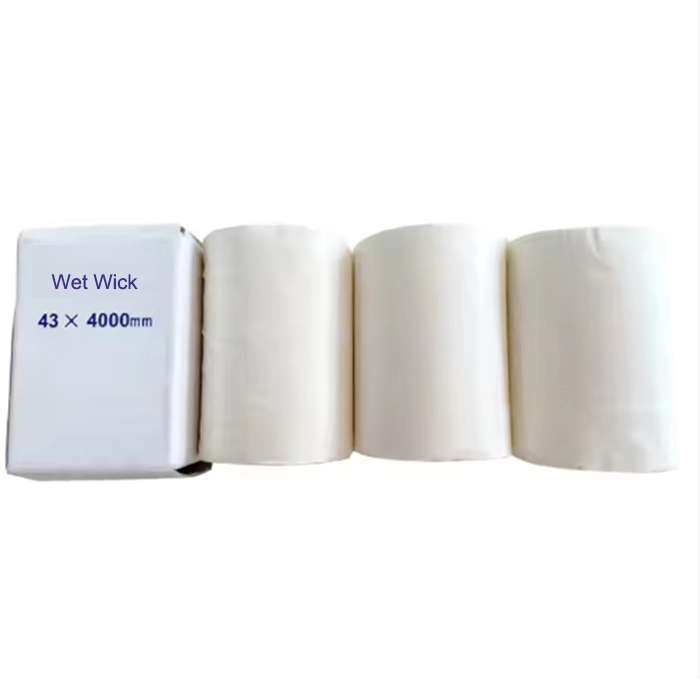

Parameter of Wet Wick for Humidity Test Chamber

Brand | LIB industry |

Model | Bulb gauze |

Product name | Wet gauze ball foam gauze |

Dimension | 43x4000mm/ volume/box |

Materials | Special "wet bulb qauze" linen |

Package | Interior plastic bag |

Outer packing | Standard carton |

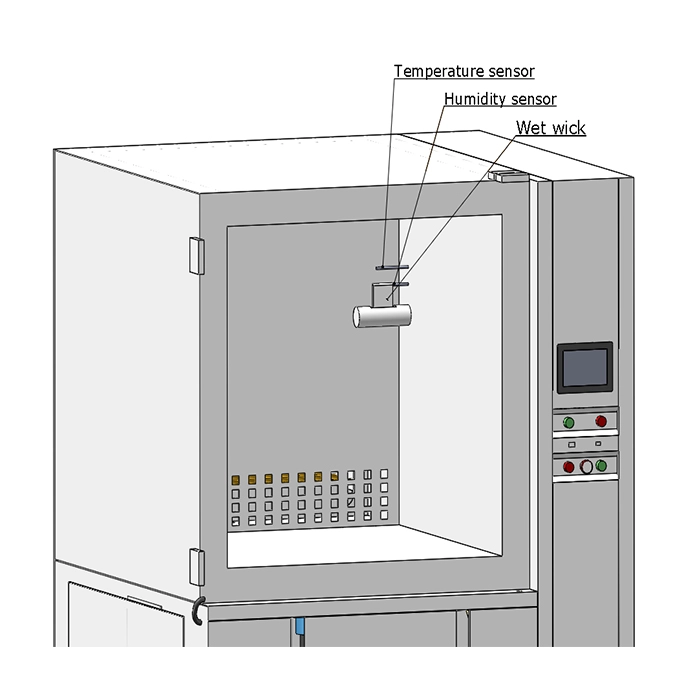

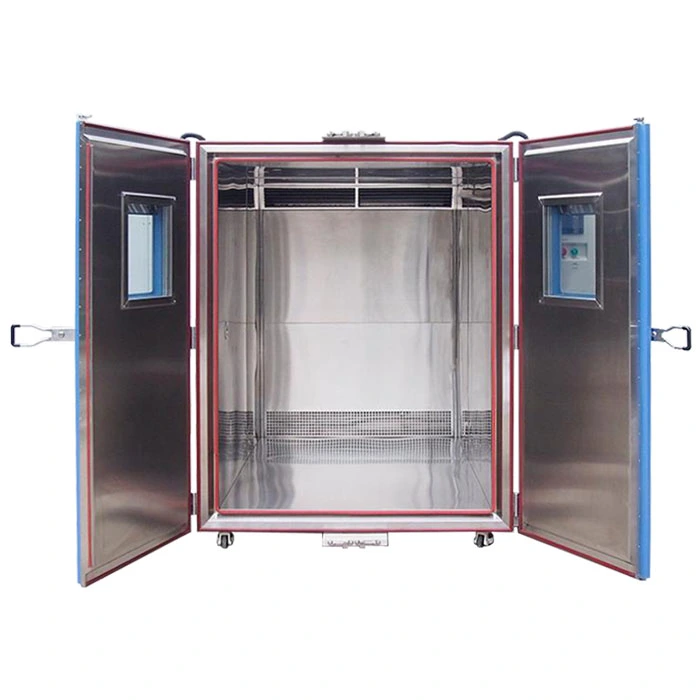

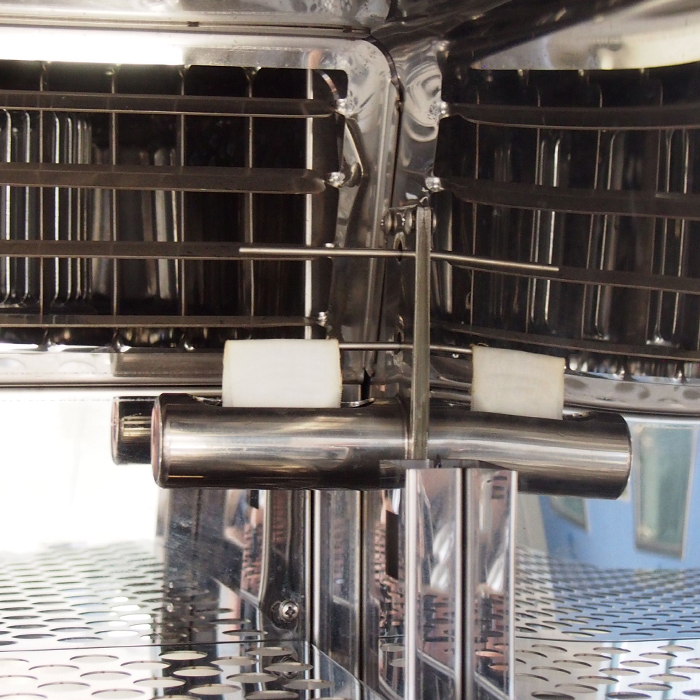

Wet Wick for humidity test chamber Hanging method

Step 1

Cut a suitable length of wet bulb gauze according to the humidity test chamber structure.

Step 2

Fully soak the wet wick in distilled or deionized water.

Step 3

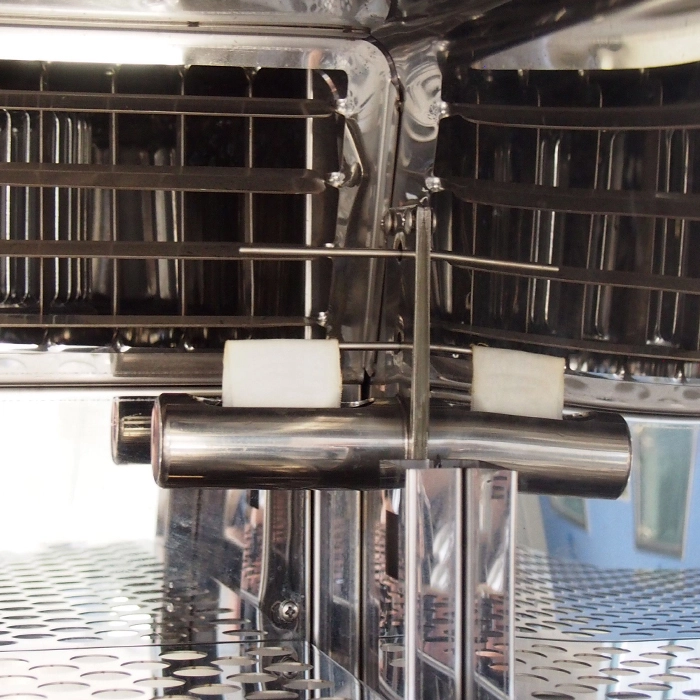

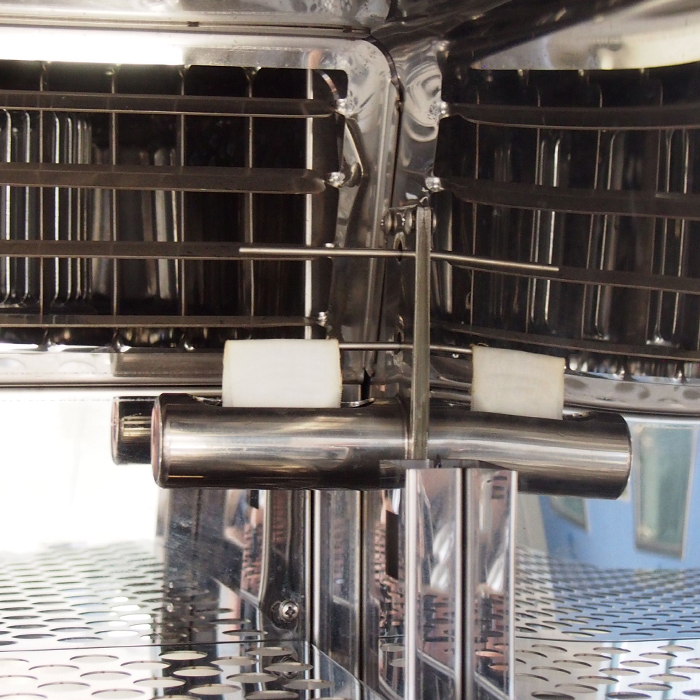

Place the upper part of the wet wick on the humidity sensor, ensuring full contact.

Step 4

Guide the lower end into the water sink to maintain continuous water absorption.

Proper hanging ensures stable evaporation and accurate wet-bulb readings.

Maintenance & Replacement Recommendations

Regularly check the sink water level and refill with distilled or deionized water

Inspect the wet wick for contamination, discoloration, or fiber damage

Replace the wet wick promptly if dirt buildup or aging is observed

Recommended replacement interval depends on test duration and humidity level

Proper maintenance helps extend sensor life and ensures long-term humidity accuracy.

Get Specifications & Quotation Today

LIB industry provides complete technical specifications, original spare parts, and reliable after-sales support for wet wick used in humidity test chambers.

Original manufacturer accessory with guaranteed compatibility

3-year system-level support philosophy applied to all genuine spare parts

Lifelong technical assistance from experienced LIB industry engineers

1–3 hour rapid remote response for installation and usage support

Stable global spare parts supply to ensure long-term chamber operation

Contact the LIB industry team today inquiry@libtestchamber.com to receive detailed specifications, compatible chamber models, and a tailored quotation.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia