Core Advantages of a Temperature Humidity Laboratory Climatic Test Chamber

1. True Climatic Reproduction

The Temperature Humidity Laboratory Climatic Test Chamber simulates real-world climate behavior, including dew-point condensation, moisture intrusion, and cyclic humidity swelling, essential for PCB coating, polymer bonding, and optical device fogging verification.

2. Dynamic Stress Profiles for Accelerated Life Testing

Supports customized rapid ramp rates up to 3–5°C/min, enabling thermal fatigue cycling, failure mode identification, and lifespan acceleration studies for aerospace components and EV battery modules.

3. Micro-Environment Stability for Precision

Designed for laboratory-grade sensitivity products such as sensors, microchips, and medical materials, maintaining ±0.5C / ±2.5%RH intra-chamber stability with turbulence-controlled airflow to avoid sample disturbance.

4. Cross-Standard Testing Platform in One Chamber

A single Temperature Humidity Laboratory Climatic Test Chamber can satisfy ISO 6270, IEC 60068-2-78, and MIL-STD-810 humidity cycling procedures without hardware modification, reducing laboratory cost and qualification time.

Temperature Humidity Laboratory Climatic Test Chamber Specifications

Model | TH-100 | TH-225 | TH-500 | TH-1000 |

Internal Dimension (mm) | 400*500*500 | 500*600*750 | 700*800*900 | 1000*1000*1000 |

Overall Dimension (mm) | 900*1050*1620 | 1000*1140*1870 | 1200*1340*2020 | 1500*1540*2140 |

Interior Volume | 100L | 225L | 500L | 1000L |

Heat load | 1000W |

Temperature Range | A : -20℃ ~ +150 ℃ B : -40℃ ~ +150 ℃ C: -70℃ ~ +150 ℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Humidity Range | 20% ~ 98% RH |

Humidity Deviation | ± 2.5% RH |

Cooling Rate | 1 ℃ / min |

Heating Rate | 3 ℃ / min |

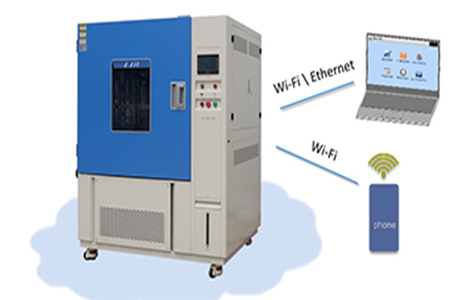

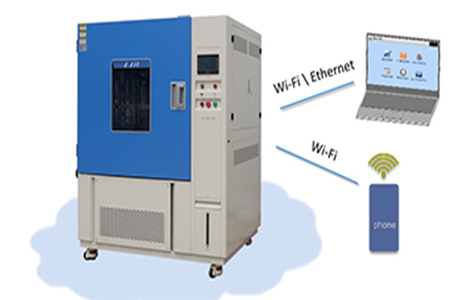

Controller | Programmable color LCD touch screen controller,PC Link, LAN interface for remote control |

Cooling system | Mechanical compression refrigeration system |

Refrigerant | Environmentally friendly refrigerant,compliant with the GWP standards requirements |

Water supply system | Automatic water supply; Water purification system |

Safety device | Humidifier dry-combustion protection; over-temperature protection; over-current protection; Refrigerant high-pressure protection; Water shortage protection, Earth leakage protection; |

Interior Material | SUS304 stainless steel |

Exterior Material | Steel Plate with protective coating |

Configuration of Temperature and Humidity Test Chamber

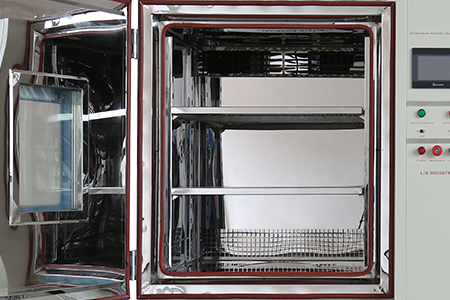

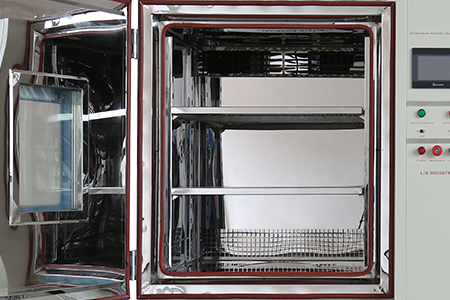

Test Workspace – Optimized Airflow with Micro-Grooved Base | SUS304 stainless steel internal workspace, corrosion-resistant and easy to clean. The bottom features a micro-grooved design with a drainage outlet, allowing condensed water to return efficiently and preventing puddling. Multi-directional air circulation ensures high temperature humidity uniformity, providing consistent exposure for all samples.

|

|

Observation Window – Anti-Fog, Heated and Large | |  |

Cable/Test Port – Flexible Interface for Instruments | Equipped with standard Ø50(Ø100 mm)insulated ports, allowing cables, power lines, or fluid pipes to connect measurement instruments, battery modules, or motion systems while maintaining chamber seal integrity. |  |

Programmable Controller – Research-Focused Logic | The touch-screen controller supports 120-step cyclic programming, curve recording, real-time trend graphs, remote monitoring, multi-language UI, and data export via USB/Ethernet—ideal for laboratory traceability and auditing. |  |

Refrigeration System – Energy-Saving, Low-Vibration Design | Using compressors and eco-friendly refrigerant. Refrigeration cascade technology, achieving rapid and stable cooling,enabling precise low-temperature performance while minimizing noise and vibration, suitable for sensitive sensors or micro-electronics testing.

|  |

Temperature Humidity Laboratory Climatic Test Chamber Testing Standards Compliance

The Temperature Humidity Laboratory Climatic Test Chamber meets a wide range of international and industry standards for environmental testing, ensuring reliable validation for laboratory research, industrial production, and product certification. Key standards include:

IEC 60068-2-38 / 60068-2-78 – Humidity and damp heat testing for electronic components and assemblies.

ISO 6270 – Determination of the resistance of coatings to humidity.

MIL-STD-810H – Environmental engineering considerations and laboratory tests for military-grade products, including humidity and temperature cycling.

ASTM D2247 – Standard practice for testing coatings in humid atmospheres.

Work with LIB industry

LIB industry provides end-to-end environmental testing solutions, from chamber selection to long-term support.

What you get:

Engineer-led solution evaluation

Custom configurations for complex tests

Fast delivery & global support

3-year warranty

Lifetime technical support

Contact: inquiry@libtestchamber.com. Send us your test plan and receive a free technical evaluation & recommendation.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia