For laboratories and manufacturers that rely on salt spray testing for product quality assurance, equipment reliability and usability are key. To meet evolving customer needs and industry standards, LIB has introduced a series of practical updates to its salt spray corrosion test chamber https://www.libtest.com/products/salt-spray-corrosion-test-chamber.html. These four new improvements focus on enhancing material safety, sample handling, environmental compliance, and overall operation—delivering a more efficient and user-friendly testing experience.

The most significant improvement is LIB’s shift to a fully integrated fiberglass-reinforced plastic (FRP) structure. Unlike traditional chambers that rely on bolted panels or partial metal enclosures, the new one-piece FRP molding offers exceptional durability and long-term resistance to corrosion.

- Corrosion Resistance: Acid fog, salt mist, and moisture no longer degrade the chamber’s housing, ensuring consistent testing environments over time.

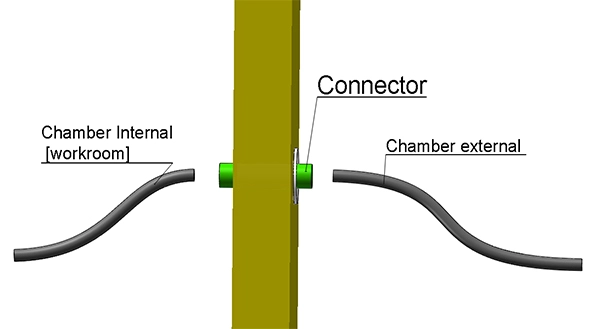

- Leak Prevention: The absence of seams and joints eliminates leakage risks, which is critical for maintaining fog concentration and internal pressure.

- Thermal Stability: FRP offers better heat retention and distribution, improving internal temperature uniformity.

This change reduces maintenance requirements and improves the long-term reliability of the test equipment—especially important for labs conducting frequent or extended tests.

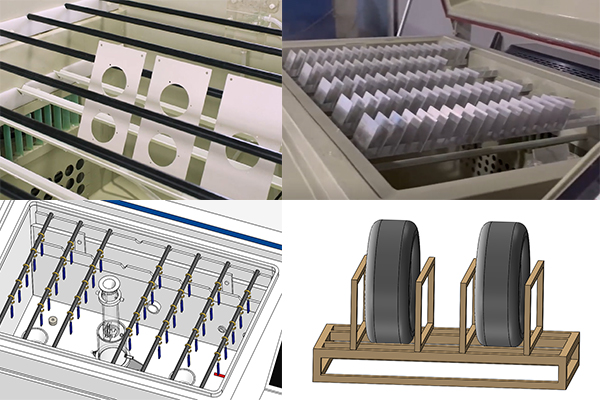

Proper sample placement is crucial for reproducibility. LIB now standardizes the use of round bars and V-groove holders to accommodate most test items. This setup simplifies positioning and promotes even fog exposure.

For users with non-standard specimens—such as cables, castings, or textiles—LIB offers a range of customized holders:

- Hook-style racks for suspended parts like wires and tubes.

- Insert panels for flat or flexible materials.

- Laser-cut 3D frames to hold complex shapes. All holder types are constructed from corrosion-resistant, non-reactive materials to maintain test purity and reliability.

All holder types are constructed from corrosion-resistant, non-reactive materials to maintain test purity and reliability.

Replacing the former asbestos base plate beneath the heating system, LIB has implemented calcium silicate boards to meet modern safety and environmental guidelines.

- Non-toxic and asbestos-free: Ensures compliance with health standards.

- Excellent heat resistance: Performs well even at high operational temperatures.

- Environmentally responsible: Contributes to safer production and end-of-life disposal. Though subtle, this material upgrade has long-term implications for user safety and operational sustainability.

Though subtle, this material upgrade has long-term implications for user safety and operational sustainability.

A practical yet often overlooked change, LIB’s new recessed door handle improves usability in several ways:

- Prevents accidental bumps and snagging in tight spaces.

- Supports a more flush, sealed door profile, helping reduce fog leakage.

- Enhances visual integration with modern laboratory equipment. This ergonomic update reflects LIB’s attention to not only the functional but also aesthetic and safety details of lab hardware design.

This ergonomic update reflects LIB’s attention to not only the functional but also aesthetic and safety details of lab hardware design.

With these four major updates—seamless FRP construction, upgraded sample holders, environmentally safe insulation, and modernized handle design—LIB’s Salt Spray Corrosion Test Chamber is more robust, user-friendly, and compliant than ever. These enhancements reinforce LIB’s core commitment: delivering reliable, customizable, and safe testing equipment for industrial and research clients worldwide.

Whether you're testing coatings, automotive parts, electronic housings, or metal coupons, LIB’s updated chambers offer the precision and durability required to meet today’s rigorous corrosion standards.

�� Explore full customization options or request a quote today at inquiry@libtestchamber.com.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia