Corrosion is one of the most costly forms of material degradation, especially for products exposed to marine or industrial environments. JIS Z 2371 provides a standardized way to simulate these harsh conditions using a controlled salt spray test chamber , allowing manufacturers to detect coating failures and material weaknesses long before products reach customers.

To comply with JIS Z 2371, a salt spray chamber must:

Maintain 35°C ± 1°C inside the test space

Generate salt mist with 5% NaCl solution at pH 6.5–7.2

Achieve a mist fall rate of 1–2 mL/80cm²/h evenly across all sample areas

LIB, a leading manufacturer of salt spray test equipment, engineers chambers to lock in these parameters with tight tolerances, ensuring repeatable and audit-proof results.

Even with the right chamber, test results can be compromised by procedural errors. Here are the top pitfalls:

Improper Sample Preparation

– Failing to clean or degrease samples leads to false failures.

Incorrect Salt Solution pH

– Deviations can accelerate or slow corrosion unnaturally.

Uneven Sample Placement

– Overlapping samples may shield surfaces from exposure.

Neglecting Calibration

– Temperature and mist output sensors must be checked regularly.

Using Non-Resistant Fixtures

– Metal racks or holders can corrode and contaminate results.

By avoiding these mistakes, you can ensure your salt spray testing provides accurate, actionable data.

Parameter | JIS Z 2371 Requirement | LIB Salt Spray Chamber |

Test Temperature | 35 °C ± 1 °C setpoint | Ambient to +60 °C operating range; ±0.5 °C fluctuation; ±2.0 °C deviation—easily sustaining a stable 35 °C setpoint. |

Salt Solution | 5% NaCl, pH 6.5–7.2 | Supports standard 5% NaCl preparation for NSS/AASS/CASS testing (user prepared). |

Fog Deposition Rate | 1–2 mL / 80 cm² · h | Specified 1–2 mL / 80 cm² · h, with fog collector & measuring cylinder for verification. |

Spray Mode | Continuous exposure (per method) | Continuous / Periodic selectable spraying. |

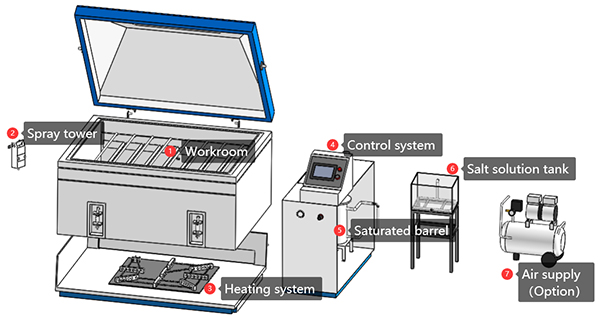

Air Preheating | Saturated air for stable humidity | Saturated air barrel (air preheating) to maintain high-RH fog environment. |

Atomization | Stable, uniform mist | Atomizer tower + spray nozzles for even distribution. |

Chamber Humidity | High-humidity fog environment | 95%–98% RH during operation. |

Controller | Stable control & repeatability | PID controller for closed-loop control. |

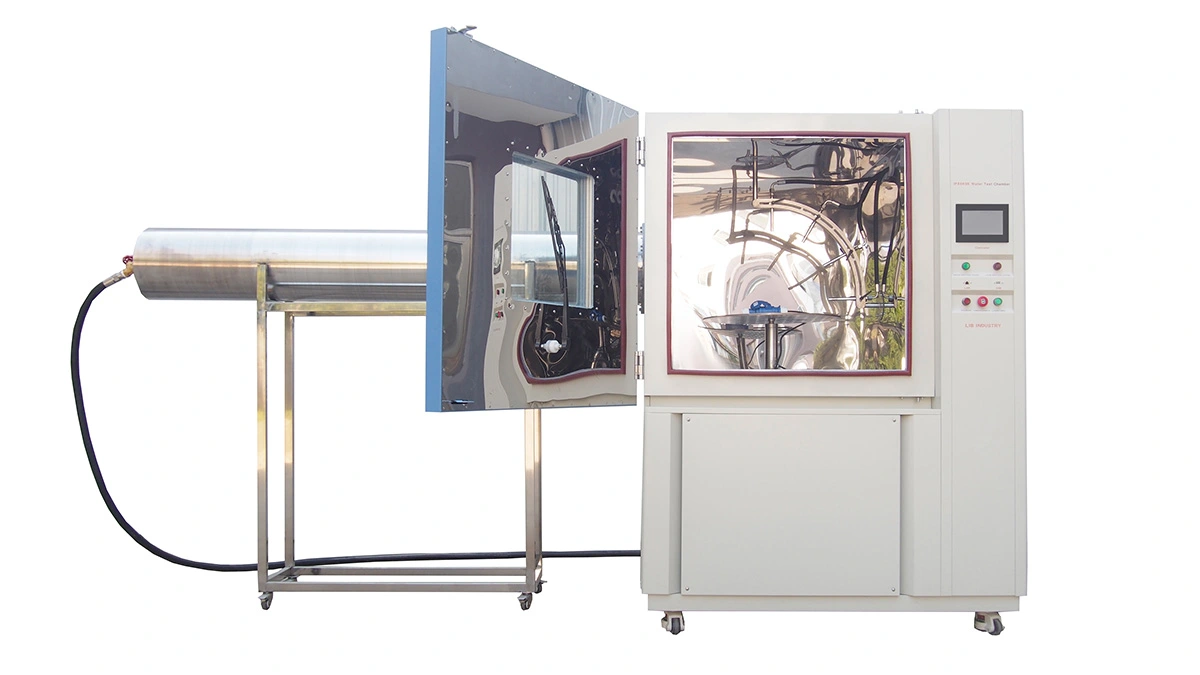

Construction | Corrosion-resistant interior | Integrally molded GRP (glass fiber reinforced plastics) chamber body for durability. |

| ||

Supported test types: standard NSS and AASS/CASS methods; models available to cover standard salt spray and cyclic corrosion needs depending on selection.

Why this matters for JIS Z 2371:

The saturated air barrel + atomizer tower architecture helps maintain a stable 35 °C fog environment with uniform spray density, which is critical for reproducible corrosion results.

Built-in fog collection hardware lets you verify the 1–2 mL/80 cm²·h deposition rate, reducing audit risk and ensuring test validity.

Standards Expertise – Full compliance with JIS Z 2371, ASTM B117, ISO 9227

Customization – From compact lab models to large walk-in salt spray chambers

Proven Track Record – Trusted by certified labs and global manufacturers in over 60 countries

One-stop Service Support – Installation, training, and spare parts availability

Meeting JIS Z 2371 isn’t just about owning a salt spray test chamber—it’s about using the right equipment, avoiding common mistakes, and ensuring every test is consistent. With decades of expertise, LIB leading manufacturer delivers chambers that transform compliance into confidence.

Get in touch with LIB today inquiry@libtestchamber.com to secure your next JIS Z 2371-compliant salt spray test chamber.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia