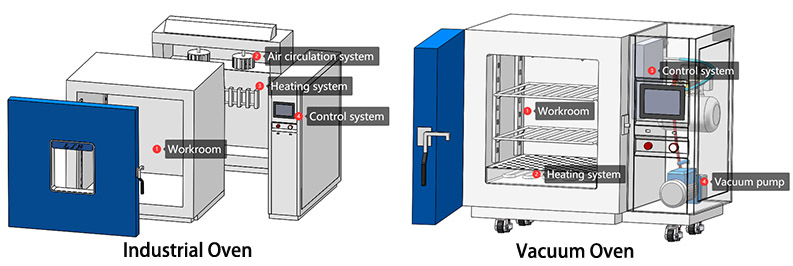

Both ovens are very common in precision manufacturing, and they reshape the production process in very different ways. Industrial ovens and vacuum ovens, these two test devices are similar from the name to the appearance, but they solve the material handling problem with differentiated technology. This article takes you through the differences.

The industrial oven adopts a forced hot air circulation system, heating the air through an electric heating heat pipe, and then forming a 2-5m/s circulating air flow by a centrifugal fan. Industrial ovens, like large blowers, are suitable for rapid dehydration of conventional materials without changing the state of the material in the environment.

The vacuum oven reduces the pressure of the chamber to 0.1-10KPa through the vacuum pump to change the environment of the material, and then heats it with the electric heating tube. Its working principle is similar to that of a space dewatering chamber, in a low pressure environment, the boiling point of water can be reduced to below 40 ° C.

Industrial Oven | Vacuum Oven | |

Temperature Range | A: Ambient ~+250 ℃ B: Ambient ~+400 ℃ C: Ambient ~+900 ℃ | +35 ℃ ~+350 ℃ |

Temperature Fluctuation | ± 0.5 ℃ | / |

Temperature Deviation | ± 2.0 ℃ | / |

Heating Rate | 6 ℃ / min | 6 ℃ / min |

Vacuum degree | / | -133pa |

Heating Element | Nichrome heater | Nichrome heater |

From the parameter point of view, the temperature range of the oven is usually higher, and the highest temperature of the LIB oven can reach 900°C or higher. The temperature range of the LIB vacuum drying oven is relatively low, between room temperature and 350°C.

Coating and curing of metal parts,textile styling treatment,drying of conventional chemical raw materials

Nanomaterials preparation,dehumidification of precision electronic components,production of heat-sensitive drugs

Oven and vacuum drying oven have differences in temperature range, working principle and application range. Which device you choose depends on your specific application needs and the nature of the substance that needs to be heated, dried or treated.

LIB can also make customized ovens or vacuum ovens according to your needs, such as size, heating rate, controller, temperature range, etc. Welcome to leave your needs, the LIB team will contact you within 24 hours.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia