Structure and Advantages of Waterproof Test Chamber

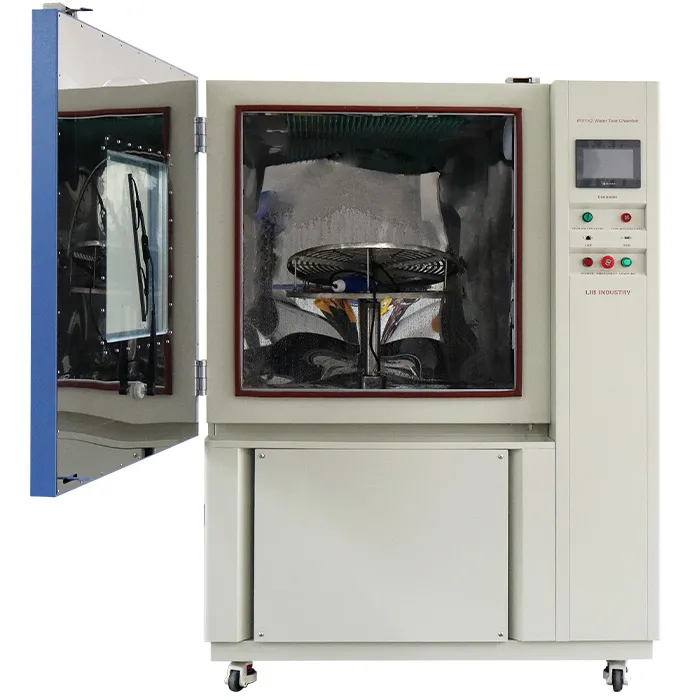

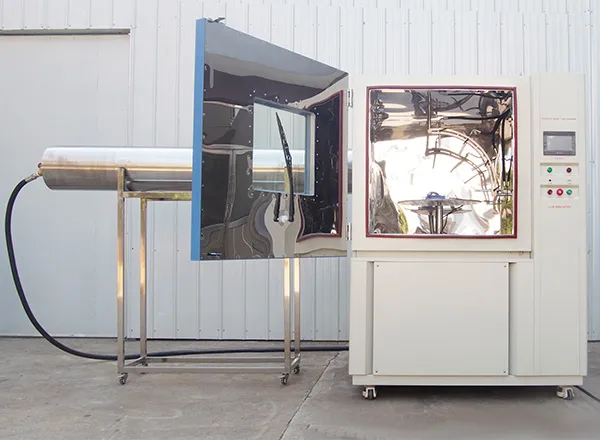

LIB waterproof test machine is designed to simulate different levels of dripping, spraying and splashing in order to assess the water resistance of the product.

1. Waterproof Test Machine BodyRobust stainless steel structure for long-term stability Constructed from solid SUS304 stainless steel All welded joints and cross-sectional surfaces are pickled for corrosion resistance Designed for continuous operation in high-humidity test environments

|

|

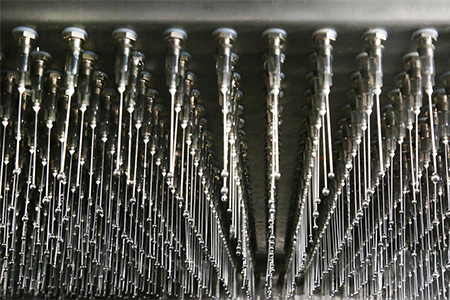

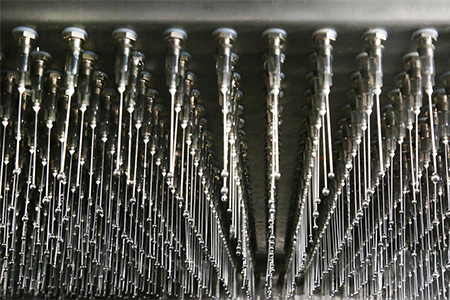

2. Drip Device (IPX1 & IPX2)Accurate control of dripping rate and distribution Includes drip tray, calibrated drip holes, and adjustable flow control IPX1 water flow rate: 1 ml/min IPX2 water flow rate: 3 ml/min Drip Tray Size (mm):600 × 600,1000 × 1000 available

The drip system precisely simulates vertical dripping conditions specified in IEC 60529, ensuring uniform water distribution across the test sample. |  |

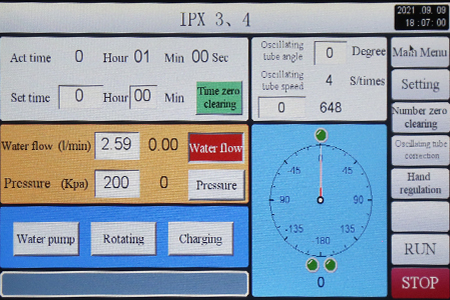

3. Oscillating Tube System (IPX3 & IPX4)Uniform spray coverage with adjustable swing angles Oscillating tube radius options: 200 mm to 1600 mm Nozzle spacing: 50 mm Nozzle diameter: φ0.4 mm Swing angle adjustable from 0 to ±180° Motor-driven oscillation ensures consistent spray movement

This design enables reliable simulation of rain and splash exposure from multiple angles, ensuring full surface coverage and repeatable test conditions |  |

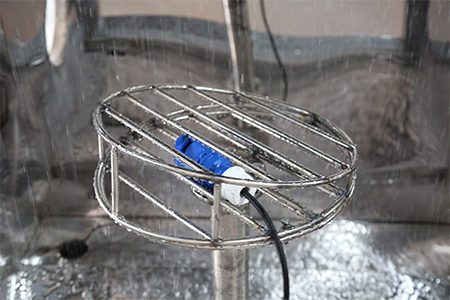

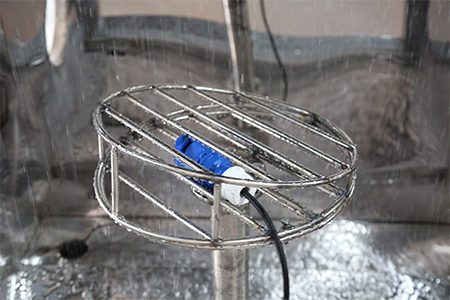

4. Sample Fixing and Turntable SystemStable positioning with powered waterproof testing Secure sample fixing prevents movement during testing Adjustable turntable height: 350–500 mm Turntable rotation speed for IPX3/IPX4: 1 RPM Equipped with a waterproof power supply device for energized testing 15° tilt dial for IPX2 testing, removable for IPX1 tests

|  |

5. Water Circulation and Treatment SystemClean water supply for stable spray performance Integrated water tank, pump, and circulation system Automatic inlet filtration down to 0.03 mm particles Supports water recycling to reduce consumption

The filtration and circulation design ensures smooth water flow, minimizes nozzle blockage, and maintains consistent spray performance during long-term operation |  |

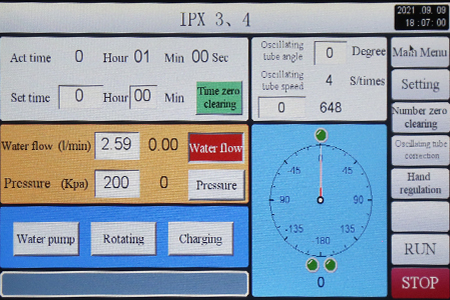

6. Intelligent Control SystemProgrammable control with real-time monitoring PID intelligent touch screen control system Adjustable parameters including oscillating angle, speed, and test duration Real-time display of test status and operating conditions Test data export supported for documentation and analysis

|  |

| Need assistance configuring IPX1–IPX6 tests for your product? LIB industry provides professional guidance on model selection, test setup, and standard interpretation.Contact us at inquiry@libtestchamber.com. |

Specifications of Waterproof Test Machine

Model | RD-800C | RD-1200C |

Internal Dimensions (mm) | 900*950*950 | 1300*1350*1370 |

Overall Dimensions (mm) | 1180*1420*1920 (excluding stainless steel tube) | 1540*1820*2200 (excluding stainless steel tube) |

Useful Volume (L) | 810 | 2400 |

Drip Tray Size | 600*600 | 1000*1000 |

Oscillating Tube Radius | 400mm | 600mm |

Water Jetting Tube |

|

|

Spraying Hole Diameter | φ0.4mm |

Hole Spacing | 50 mm |

Swing Angle of Oscillating Tube | 0 ~ ±180° (Adjustable) |

Jet nozzles | IPX5: Dia6.3mm, IPX6: Dia12.5mm |

Jet distance | 2.5~3meter |

Turntable Rotation Speed | 1r/min (Adjustable speed) |

Controller | Programmable color LCD touch screen controller, Ethernet connection, USB port |

Water supply system | Water tank, booster pump, Automatic water supply, Water purification system |

Safety Device | Over-temperature Protection; Over-current Protection; Water Shortage Protection; Earth leakage Protection; Phase Sequence Protection |

Exterior Material | Steel Plate with protective coating |

Interior Material | SUS304 stainless steel |

Observation Window | Double layer insulating glass with wiper |

How the Waterproof Test Machine Works

Standardized waterproof testing based on IEC 60529

The waterproof test machine performs standardized water exposure tests by precisely controlling water flow, spray angle, and test duration.

IPX1 Test: Vertical dripping onto a rotating sample at a controlled flow rate

IPX2 Test: Vertical dripping with the sample tilted at 15°

IPX3 Test: Oscillating tube sprays water from multiple angles to simulate rainfall

IPX4 Test: Increased spray intensity and coverage for more severe splash conditions

During testing, water is continuously filtered and recycled to maintain stable test conditions. After completion, samples are evaluated for water ingress, leakage, or functional failure to determine compliance with the specified IP rating.

CTA-Engineered for Compliance.Supported for Life.

With LIB industry, your waterproof test machine is backed by a 3-year warranty and lifelong technical guidance.

From IPX test setup to daily operation and maintenance, our engineers provide professional, standard-oriented support.

In the event of an unresolved fault, a replacement unit is supplied without additional cost, minimizing downtime and certification risk.

Spare parts are readily available from global warehouses, with delivery in 7–15 days.

Talk to LIB industry inquiry@libtestchamber.com about your IPX waterproof testing requirements

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia