When most people think of a xenon test chamber, they imagine rows of flat, rectangular samples mounted on a rotating rack. But what if your product is a large, perfectly round disc? Recently, LIB worked on an unusual case: a 320 mm diameter, 4 mm thick disc made of PMMA (acrylic), tested for at least 1,000 hours of simulated sunlight exposure.

The challenge was not just the long exposure time — it was ensuring that the xenon light source illuminated the entire disc surface evenly without introducing stress or damage during testing.

A xenon test chamber is the gold standard for simulating full-spectrum sunlight, including visible light, UVA, and infrared. For PMMA, which is widely used in optical components and signage, UV exposure can lead to:

Yellowing and color shifts

Reduced light transmittance

Surface micro-cracking or crazing

By recreating years of sunlight in weeks or months, a xenon test chamber helps manufacturers evaluate durability, compare material grades, and verify UV stabilizer performance.

To make results comparable and credible, testing should follow recognized standards:

ISO 4892-2 | Methods for xenon-arc exposure of plastics (filter types, black-panel temperature, spray options). |

ASTM G155 | Operating practice for xenon-arc equipment (cycles, irradiance levels, lamp operation). |

For plastics like PMMA, a common setup is 0.35 W/(m²·nm) at 340 nm, with a black-panel temperature of around 63 °C, and an exposure cycle of 102 minutes light + 18 minutes light with water spray (spray is optional depending on end-use conditions).

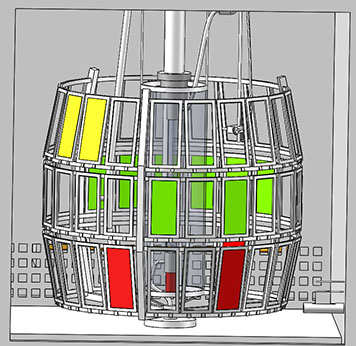

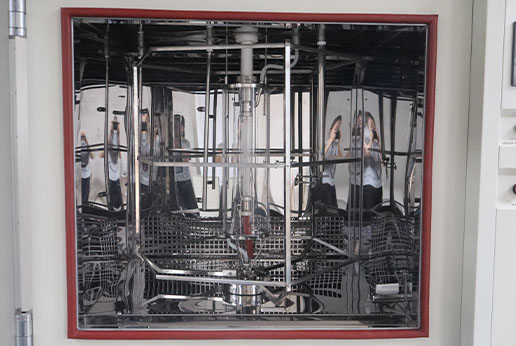

Here’s where things get interesting. Most xenon test chambers — including LIB’s XL Series — use rotating specimen racks optimized for rectangular coupons.

A 320 mm round disc requires:

Custom rotating plate | Larger surface area to hold the disc securely while ensuring face-on illumination. |

Soft, stress-free clamps | Silicone or polymer pads to avoid inducing stress cracks in PMMA. |

Balanced rotation | Preventing wobble keeps lamp distance constant for uniform irradiance. |

LIB specializes in custom fixture design, so adapting the standard xenon arc chamber for unusual shapes is part of our service. This ensures that every part of the disc receives the same light dose throughout the test.

During and after testing, we recommend measuring:

Light transmittance (UV-Vis spectrum)

Haze and optical clarity

Color change / Yellowing index

Surface micro-defects under magnification

Documenting these changes helps you understand material performance and make design or material improvements before mass production.

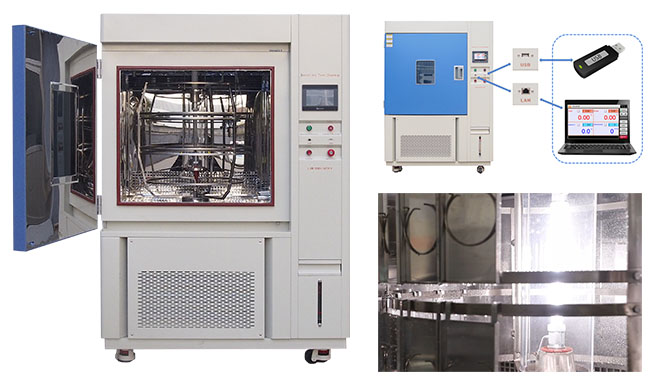

LIB’s xenon test chambers are built for flexibility — from standard rectangular samples to oversized, irregular, or round specimens. With features such as:

Programmable irradiance and temperature control

Daylight or window-glass filter options

Integrated water spray and humidity control

Customizable sample holders and rotating racks

…you can run tests that precisely match your real-world conditions.

A xenon test chamber isn’t just for standard lab coupons — with the right customization, it can handle almost any shape or size, including large PMMA discs. By simulating 1,000 hours of sunlight exposure in a controlled environment, you can predict long-term performance, validate material choices, and reduce product failure risks.

Ready to test your product under realistic sunlight simulation?

Contact LIB today inquiry@libtestchamber.com to discuss your xenon test chamber requirements — from standard models to fully customized fixtures designed for your specific parts.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia