In the reliability verification of industrial products, temperature testing is one of the most fundamental and crucial means. Low-temperature testing equipment is widely used in fields such as electronics, electrical engineering, automobiles, and materials. However, when the testing temperature requirement drops below -100℃, traditional low-temperature test chambers are no longer competent. At this point, the cryogenic test chamber becomes the ideal choice for simulating extremely cold environments.

This article will analyze the key differences between the cryogenic test chamber and the ordinary low-temperature test chamber, and introduce the LIB cryogenic test equipment solution.

Ordinary low-temperature test chambers are usually suitable for simulating the storage, transportation or usage performance of products in cold environments. Its typical temperature range is:

-20℃, -40℃, -60℃, and some can reach -70℃

Applicable objects include

Consumer electronics, auto parts, plastic materials, LED lighting, etc

The main features of this type of equipment:

Refrigeration is carried out by single-stage or double-stage compressors

The temperature and humidity can be programmed and controlled

Low cost, compact structure and simple operation

The Cryogenic chamber is a dedicated device for ultra-low temperature testing, with a temperature range typically from -100℃ to -150℃. It is mainly used to simulate extreme environments, such as:

Aerospace equipment

Superconducting materials, special alloys

Freezing components in medical devices

Research on extremely cold physical phenomena by scientific research institutions

To cope with extremely low temperatures, the Cryogenic equipment has the following characteristics:

Use a cascade refrigeration system

Reinforced insulation structure to prevent frosting or cold Bridges

III. Comparison of Core Differences

Feature | Standard Low Temperature Chamber | Cryogenic Chamber |

Temperature Range | -20°C ~ -70°C | -100°C ~ -150°C or lower |

Suitable For | General electronics, automotive plastics | Advanced alloys, aerospace materials |

Cooling Method | Single or dual-stage compressor | Cascade system |

Structural Requirements | Standard insulation | Enhanced insulation and anti-frost design |

Cost | Medium to low | Higher, due to technical complexity |

The cryogenic test chamber not only has a lower temperature, but more importantly, it can achieve stability, safety and long-term operation capability at extremely low temperatures.

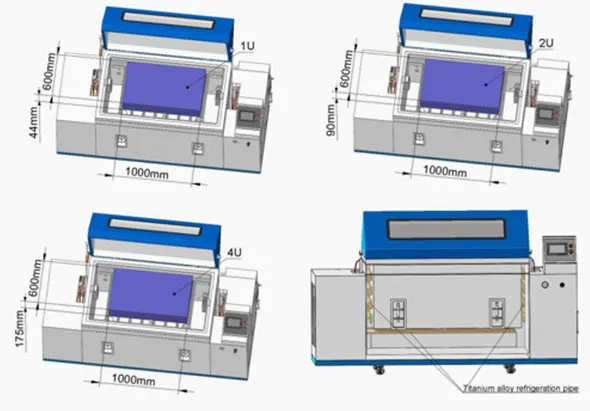

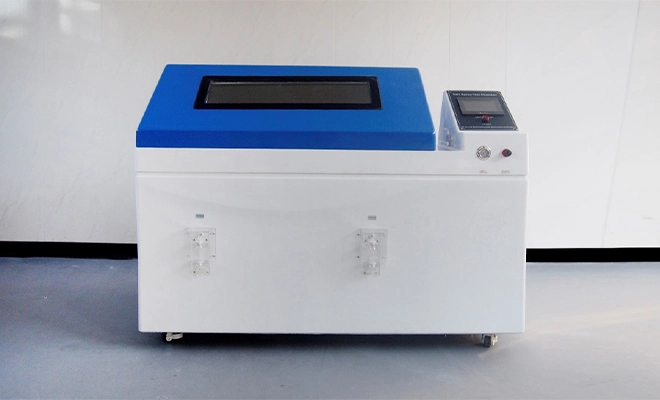

LIB offers multiple standard models of cryogenic test chambers.

Advantages of the LIB CF series cryogenic test chamber:

Model | CF-100 | CF-225 | CF-500 | CF-800 | CF-1000 |

Interior Volume | 100L | 225L | 500L | 800L | 1000L |

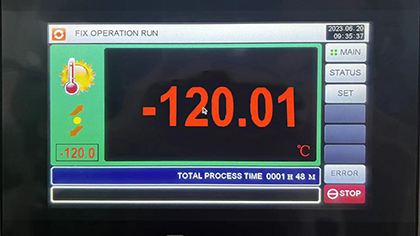

Temperature Range | -120℃ ~ +150℃ | ||||

Temperature Fluctuation | ± 0.5 ℃ | ||||

Temperature Deviation | ± 2.0 ℃ | ||||

Cooling Rate | 1 ℃ / min | ||||

Heating Rate | 3 ℃ / min | ||||

Cooling system | Mechanical compression refrigeration system,Cascade compressor | ||||

Controller | Programmable color LCD touch screen controller,Ethernet connection | ||||

| |||||

Safety configuration: over-temperature protection, anti-condensation air duct, multi-level alarm system

Support for customization: The size of the workroom and the position of the openings can be customized according to the size of the customer's samples and the testing standards

When choosing equipment, it is recommended to make judgments from the following dimensions:

Test temperature requirement: If the test temperature is below -70℃, it is recommended to choose cryogenic equipment

Product attributes: Whether it is made of special materials, high-reliability parts or used in extreme environments

Budget and performance matching: For general tests, choose a regular low-temperature chamber; It is recommended to invest in cryogenic chambers for scientific research and high-end manufacturing

Recommended suggestions:

If the test object is a common electronic device or plastic part, a common low-temperature test chamber can meet the requirements. If the test task involves aerospace materials, bioengineering or special alloys, the LIB cryogenic chamber will be a more reliable choice.

The Cryogenic chamber is not a "colder" ordinary test chamber, but a professional system designed to address the challenges of extreme temperatures. Its core advantages lie in temperature accuracy, safety performance and structural reliability under extremely cold conditions.

LIB is committed to providing customers with precise, efficient and reliable environmental testing solutions. Welcome to contact us for customized Cryogenic testing solutions.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia