In today’s fast-paced industrial and materials landscape, ensuring the longevity and corrosion resistance of metal, plastic, and coated components is no longer optional—it’s essential. Yet many manufacturers face a recurring challenge: how to reliably replicate years of environmental exposure in a controlled, accelerated, and repeatable laboratory setting. Without the right testing solution, corrosion failures, recalls, and warranty claims can become costly realities.

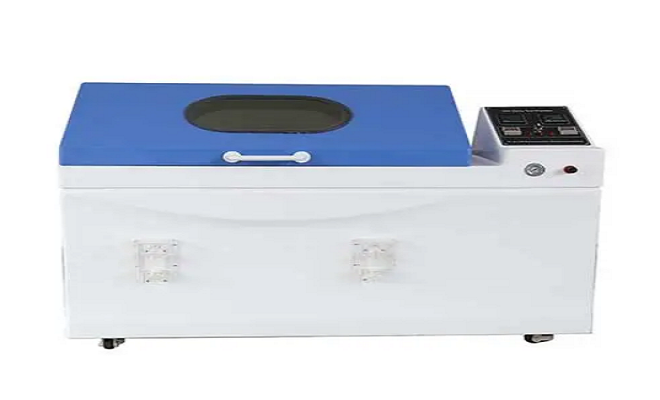

This is where LIB industry salt spray cabinet solutions excel, providing precise, accelerated, and fully customizable corrosion testing capabilities. Designed to meet ASTM G85 and other international standards, LIB industry’s salt spray corrosion test chamber systems deliver repeatable results while offering flexibility to match any industrial or research requirement.

|  |

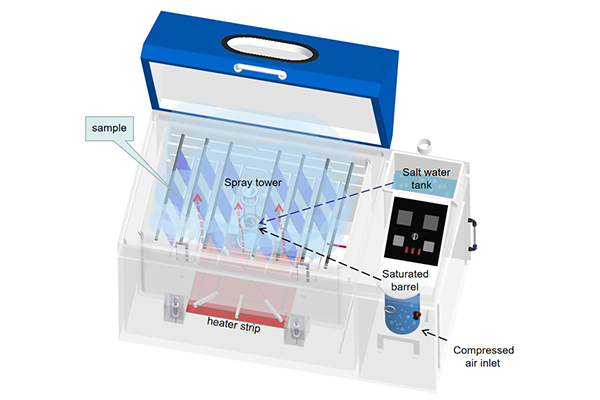

Unlike standard testing equipment, LIB industry salt spray cabinets are engineered with meticulous attention to temperature, humidity, pH, and deposition rates. Each salt spray corrosion test chamber ensures consistent environmental conditions, allowing engineers to detect coating weaknesses, evaluate metal alloys, and assess component durability with confidence.

Key parameters of LIB salt spray cabinets include:

· Temperature range: 10–90 °C

· Humidity control: up to 98% RH

· pH control: 2.5–3.3 for acidified solutions

· Deposition rate: 1–2 mL/80 cm²·h

· Chamber volume options: 110 L to walk-in systems

· Spray system: Single or multiple nozzles, uniform fog distribution

With these precise controls, LIB industry ensures every test—whether neutral salt spray (NSS), acetic acid salt spray (AASS), copper-accelerated (CASS), or SO₂-enriched—is repeatable, traceable, and meaningful.

Type | Key Features | Temperature & Humidity Range | Test Cycle / Mode | |

Basic Salt Spray Cabinet | Single spray tower for uniform deposition | +10 ℃ ~ +90 ℃ 95% ~ 98% RH | Continuous salt spray |  |

Alternates salt spray, high humidity, and dry-air purges | +10 ℃ ~ +90 ℃ 30% ~ 98% RH | Programmable: ¾-h spray, 2-h dry air, 3¼-h soak |  | |

Salt spray combined with controlled SO₂ introduction; NaOH neutralization | +10 ℃ ~ +90 ℃ 30% ~ 98% RH | Configurable SO₂ cycles |  |

This structured overview highlights how LIB industry salt spray corrosion test chamber solutions meet diverse testing needs, from standard coatings to complex industrial environments. With precise control and customizable cycles, every chamber ensures repeatable, reliable, and real-world relevant corrosion testing.

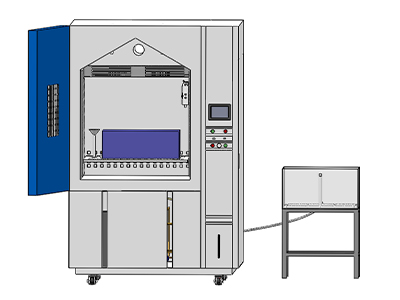

LIB industry doesn’t just provide standard salt spray cabinets; they deliver fully customizable solutions to fit any laboratory or industrial setup:

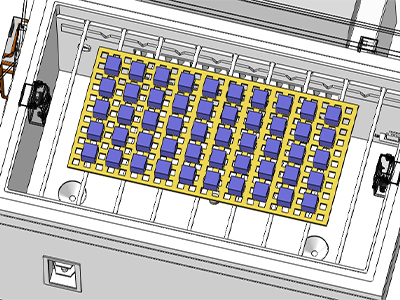

· Size customization: Small desktop unitsfor R&D or QC; large walk-in chambers for assemblies, panels, or batch production.

· Flexible sample racks: Modular grooves and bars for irregular geometries or large components.

· Optional test modes: NSS, AASS, CASS, cyclic corrosion, SO₂ packages—each configurable for decorative, automotive, or industrial applications.

· Enhanced features: Explosion-proof designs, IP-rated modules, and combined environmental simulations for comprehensive material evaluation.

|  |  |

LIB industry’s commitment to precision extends to long-term maintenance: deposition uniformity, temperature and humidity stability, nozzle cleaning, and stirring inspection ensure reproducible results over years of testing.

With over 16 years of experience, LIB industry has established itself as a leading manufacturer of salt spray cabinets and corrosion test solutions. Their extensive inventory and R&D-backed designs allow for immediate response to complex testing needs. Whether you need a standard salt spray corrosion test chamber or a fully customized cyclic or SO₂ system, LIB industry guarantees:

· Rapid response: 1–3 hours to provide a tailored testing plan and exclusive quotation.

· Global after-sales support: Three-year warranty, lifetime technical assistance, and worldwide service points.

· Fast delivery: Standard units in 7–15 days, custom solutions optimized for your schedule.

Every solution is engineered to give manufacturers peace of mind, accelerate product development, and ensure compliance with ASTM and international standards.

Don’t leave corrosion testing to chance. Contact LIB industry inquiry@libtestchamber.com now to discuss your specific testing requirements. Within 1–3 hours, receive your exclusive quotation and a complete testing plan tailored to your laboratory or production line.

Benefit from a 16-year legacy of precision, reliability, and global support, and equip your team with a salt spray cabinet or salt spray corrosion test chamber that ensures durable, high-quality results every time.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia