Calibration and Accuracy of Rain Test Chambers

Calibration and accuracy are crucial aspects of rain test chambers to ensure reliable and repeatable test results. Calibration involves verifying and adjusting the performance of the chamber to align with established standards and specifications. Precise calibration is necessary to ensure that the rain test chamber accurately simulates real-world weather conditions.

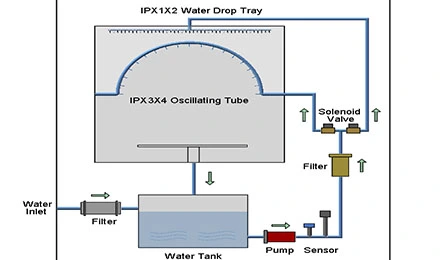

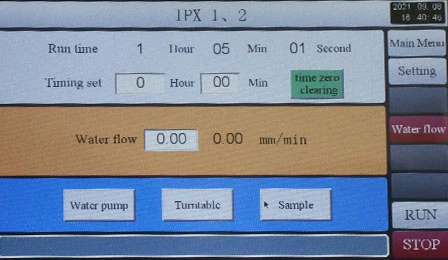

To maintain accuracy, rain test chambers typically undergo regular calibration checks using traceable reference devices, such as calibrated rain gauges or flow meters. These devices measure the water flow rate and intensity within the chamber, which can be compared against the desired test parameters.

The calibration process includes adjusting factors such as water flow rate, drop size, and distribution patterns to ensure consistency and accuracy. Additionally, the chamber's sensors, control systems, and data acquisition equipment should also be periodically calibrated to ensure their accuracy in measuring and recording test parameters.

Regular maintenance, cleaning, and calibration of the rain test chamber are essential to ensure accurate and reliable test results, especially for ip x3. Adhering to calibration procedures and good laboratory practices helps to minimize errors and uncertainties in rain testing, providing confidence in the results obtained from rain test chambers.