Key Features & Benefits of IP67 Test Equipment

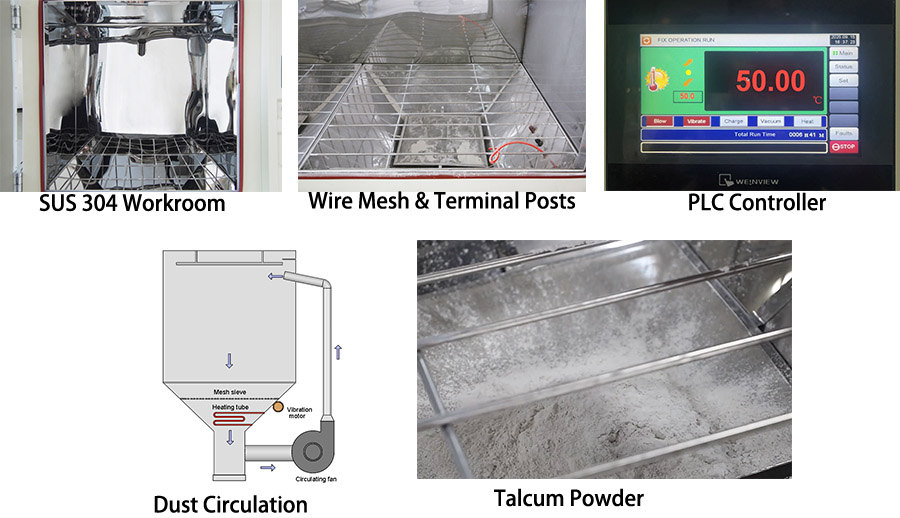

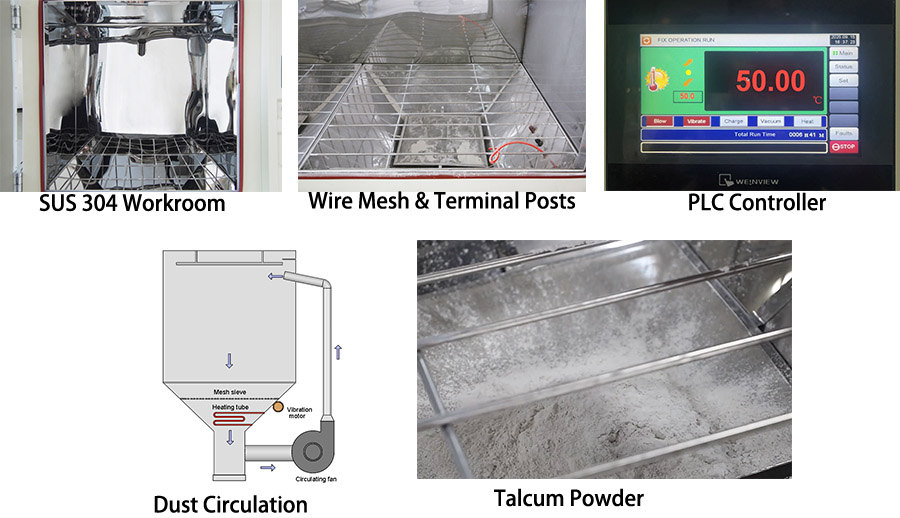

IP6X Dust Test Equipment — Dust-Tightness Verification

1. Precise Dust Simulation (IEC 60529 IP6X)

The IP6X dust test equipment accurately controls dust concentration and particle size using standardized talcum powder with a nominal wire gap of 75 μm and wire diameter of 50 μm, ensuring fully compliant and repeatable IP6X test conditions.

2. Sealed Chamber Structure for Reliable Results

A concatenated chamber design with silicone sealing strips, electromagnetic door locks, and multi-layer sealing effectively prevents dust leakage during long-duration tests, maintaining internal pressure stability and protecting the laboratory environment.

3. Uniform Dust Circulation & Airflow Control

An integrated dust circulation and stirring system distributes dust vertically throughout the working space. Stable airflow speed is maintained during the entire test cycle, supporting continuous dust blowing and settling tests up to 99 h 59 min.

4. Industrial-Grade Materials & Observation Design

The interior is manufactured from SUS304 stainless steel, offering excellent corrosion resistance and easy cleaning after testing. A large transparent observation window with dust wiper allows real-time monitoring without compromising chamber tightness.

5. Flexible Test Capacity & Sample Power Supply

Available chamber volumes range from 800 L to 2000 L, suitable for different DUT sizes. A built-in dust-proof 16 A power outlet allows powered testing of samples during dust exposure.

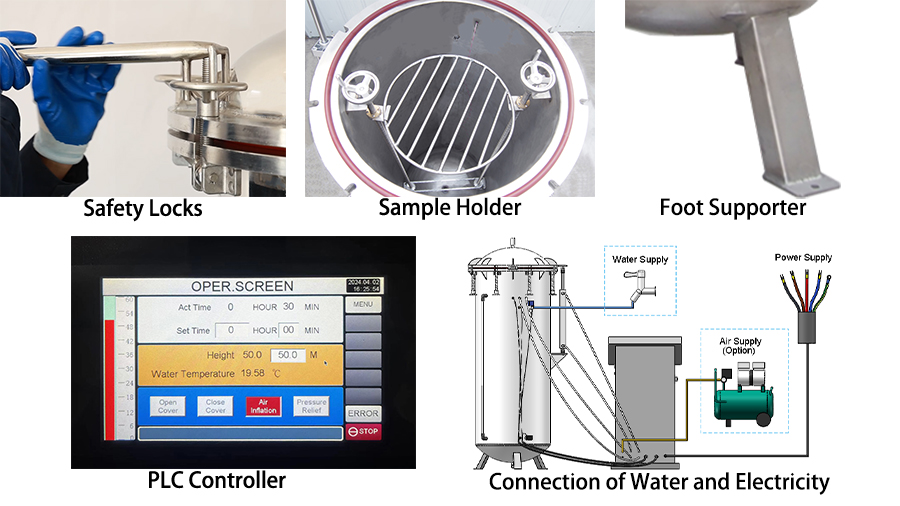

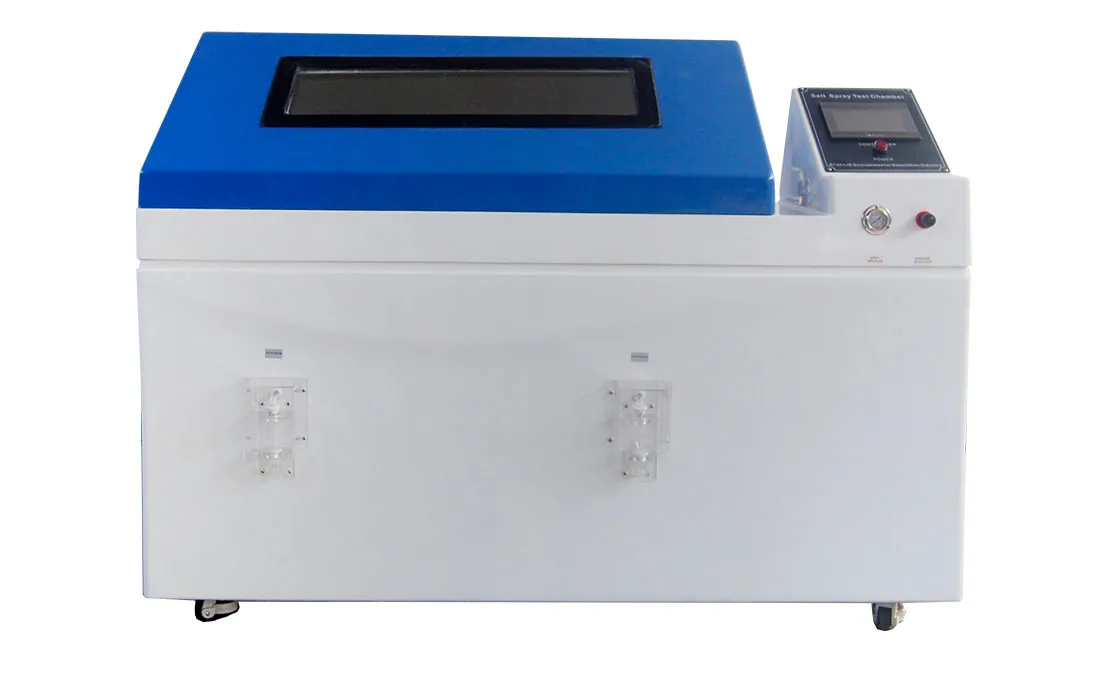

IPX7 Water Immersion Test Equipment — Waterproof Performance Validation

1. Accurate Immersion Depth & Pressure Simulation

The IPX7 water immersion test equipment simulates immersion depths equivalent to 1–50 m water pressure, with a maximum pressure of 50 bar, fully meeting IPX7 requirements and supporting extended immersion validation.

2. Uniform Pressure Test Environment

The cylindrical immersion tank design ensures even water pressure distribution on all surfaces of the DUT. An adjustable internal sample holder supports loads of up to 50 kg, accommodating a wide range of product sizes and weights.

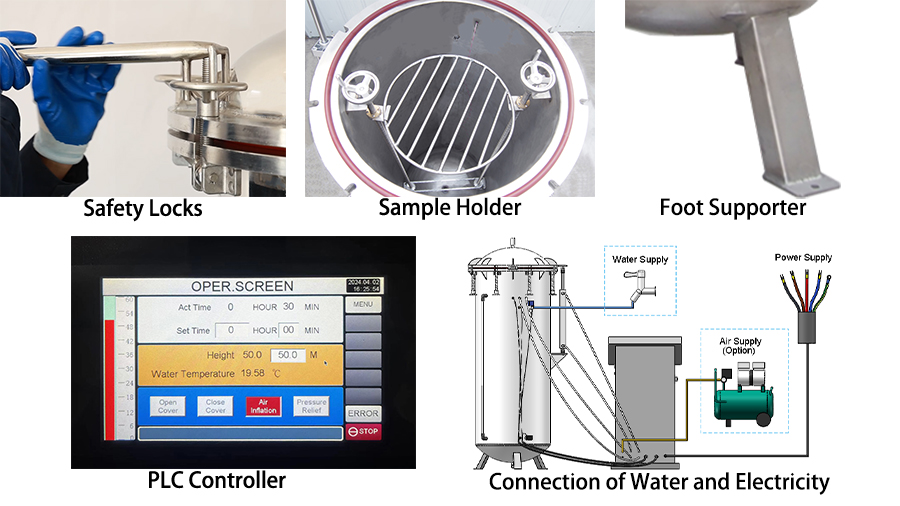

3. Secure Locking & Pneumatic Lid Operation

The equipment is equipped with high-strength manual pressure locks, with quantity customizable according to tank size. A pneumatic lid system, controlled via the touch screen controller, enables safe one-button opening and closing.

4. Robust Tank Construction for Long-Term Use

The immersion tank is constructed from 15 mm thick A3 steel plate, providing high structural strength. Key wetted components are corrosion-resistant, ensuring durability under repeated high-pressure immersion cycles.

5. Stable Water Supply & Control System

An integrated storage water tank with automatic water supply system ensures stable water level control throughout the test, improving repeatability and reducing operator intervention.

Specifications of IP67 Test Equipment

IP6X Dust Test Equipment

Model | DI-800 | DI-1000 | DI-1500 | DI-2000 |

Internal Dimension (mm) | 800*1000*1000 | 1000*1000*1000 | 1000*1500*1000 | 1000*2000*1000 |

Overall Dimension (mm) | 1040*1450*1960 | 1330*1450*1960 | 1330*1950*1990 | 1330*2450*1990 |

Useful Volume (L) | 800 | 1000 | 1500 | 2000 |

Temperature Range | Ambient ~ +50℃ |

Humidity Range | < 30% RH |

Normal Wire Diameter | 50um |

Nominal Width of a Gap Between wires | 75um |

Fight Time | 0 ~ 99H59M |

Blowing Time | 0 ~ 99H59M |

Specimen Power Outlet | Dust-proof socket 16A |

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Safety Device | Over-temperature Protection; Over-current Protection; Earth Leakage Protection; Phase Sequence Protection |

Exterior Material | A3 Steel Plate with protective coating |

Interior Material | SUS304 stainless steel |

Standard Configuration | Sample shelf, dust wiper, talcum powder(5kgs) |

| Power | AC380V 50Hz |

|

IPX7 Water Immersion Test Equipment

Model | R78-600 |

Internal Dimensions (mm) | Diameter600*Height1500 |

Overall Dimensions (mm) | Diameter800*Height1800 |

Pressure | 50m water depth pressure |

Open Mode | Pneumatic lid |

Material | A3 steel plate,wall thickness 15mm |

| Water Supply System | Storage water tank,Automatic water supply |

|

Working Principle of IP6X Test Equipment

IP6X Dust Test Working Principle

The IP6X dust test equipment simulates a controlled dusty environment using standardized test dust. Airflow and circulation systems distribute dust evenly within the chamber while maintaining a sealed internal environment.

After the specified test duration, the DUT is inspected to confirm that no visible dust has penetrated the enclosure.

IPX7 Water Immersion Test Working Principle

The IPX7 test equipment evaluates waterproof performance by immersing the DUT in water at a specified depth and duration. Uniform water pressure is maintained throughout the test.

After immersion, the DUT is examined to ensure no water ingress and normal functional performance.

Why Choose LIB industry for IP67 Testing

Extensive experience in environmental test equipment manufacturing

Full compliance with IEC, ISO, MIL, and UL standards

Custom solutions for non-standard DUT sizes and test requirements

3-year warranty and lifelong technical support

24/7 English-speaking service team for immediate guidance

LIB industry delivers not only test equipment, but a complete and dependable IP67 testing solution tailored to your certification and production needs.Contact LIB industry inquiry@libtestchamber.com to receive a technical proposal and quotation.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia