Dust infiltration remains one of the most critical threats to electronics and components. Fine particles can penetrate delicate circuits, reduce performance, compromise safety, and shorten product lifespan. Many manufacturers face the urgent question: how can products reliably meet IP5X and IP6X ingress protection standards while saving time and resources?

|  |

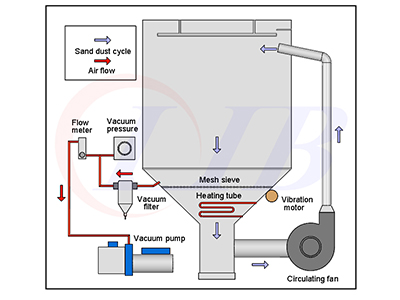

LIB IP6X IP5X ingress test chamber delivers precise, repeatable testing to ensure electronics and components withstand the harshest dust environments,by simulating real-world dust conditions with controllable dust concentration, airflow, vibration, and temperature.

Understanding IP ratings is essential for product compliance:

· IP5X: Protects against dust sufficient to prevent harmful deposits, but not fully dust-tight.

· IP6X: Fully dust-tight; no dust enters under standard test conditions.

Testing with an IP6X IP5X ingress test chamber ensures products meet international standards (IEC 60529, ISO 20653, MIL-STD-810G), increasing customer trust and product reliability in dust-prone environments.

LIB industry’s dust test chamber simulates the exact dust conditions products may encounter in real-world environments.

Key advantages include:

Fine dust with 50 μm particle size, adjustable wind speed (1–5 m/s), vibration (0–60 Hz), and temperature from ambient to +50℃ ensures products are tested under conditions that closely resemble actual usage.

Ensures uniform dust distribution for realistic testing conditions. LIB industry provides free talcum powder, which can be recovered and reused for multiple tests.

|  |

Programmable dust blowing, vibration, and test duration reduce human error.

|  |

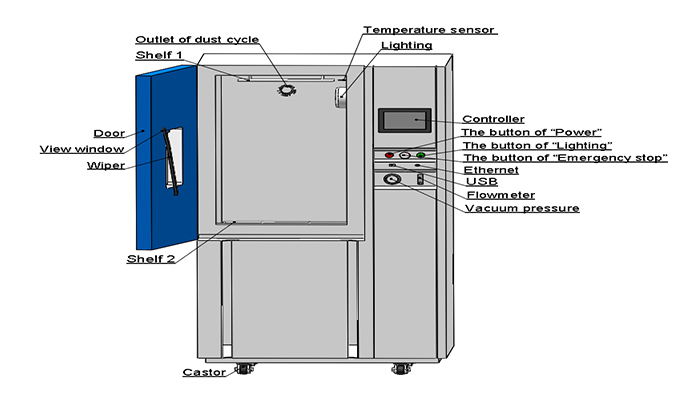

Large observation windows with manual dust removal brush and integrated lighting and electromagnetic door locks allow operators to monitor tests safely.Dual-layer seals prevent powder leakage.

|  |

SUS304 stainless steel interior and A3 coated steel exterior resist abrasive dust and ensure long-term durability.

Supports hanging sample racks and grid-style shelves, allowing simultaneous testing of multiple products.

|  |

After testing, a separate vibration mode removes powder adhering to the interior walls, making maintenance fast and simple. These features ensure electronics and components are thoroughly tested under realistic dust conditions, giving engineers confidence in product reliability and compliance with IP5X/IP6X standards.

Model | DI-800 | DI-1000 | DI-1500 | DI-2000 |

Useful Volume (L) | 800 | 1000 | 1500 | 2000 |

Temperature Range | Ambient ~ +50℃ | |||

Humidity Range | <30% RH | |||

Dust Particle Size | 50 μm | |||

Wind Speed | 1–5 m/s | |||

Vibration Frequency | 0–60 Hz | |||

Test Duration | 0–99h59m programmable | |||

Sample Power Outlet | 16A dust-proof | |||

Controller | LCD touch screen, Ethernet | |||

Standards | IEC 60529 (IP5X/IP6X), ISO 20653, IEC 60068-2-68, MIL-STD-810G | |||

| ||||

LIB industry also provides a complete suite of IP testing solutions:

· IP Water Spray and Rain Test Chambers : IPX1–IPX9K waterproof certification

· Customized Dust Test Chambers: For unique product dimensions or specialized testing

This one-stop solution ensures manufacturers can consolidate all IP compliance testing under one experienced provider.

With 16+ years of experience, LIB industry ensures electronics and components undergo rigorous, reliable testing. Our extensive inventory and rapid customization allow immediate deployment.

Global support includes:

3-year warranty and lifetime maintenance

On-site service and free training

Worldwide service network(US UK Canada Malaysia)

Act now: Don’t risk dust-induced failures. Contact LIB industry today to share your testing requirements and secure a custom IP6X IP5X ingress test chamber solution and quotation within 1–3 hours.Ensure your products are dustproof, reliable, and compliant—partner with LIB industry today at inquiry@libtestchamber.com.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia