Performance Advantages of Hydrolysis Aging Test Stability Chamber

1.Sustained High-Humidity Capability

Engineered for continuous operation at up to 98% RH, preventing humidity drift during extended hydrolysis aging cycles.

2. Thermal Stability for Long Aging Durations

Temperature ranges from –20 / –40 / –70 °C to +150 °C, with fluctuation controlled within ±0.5 °C, ensuring consistent thermal stress throughout the test period.

3. Uniform Moisture Exposure

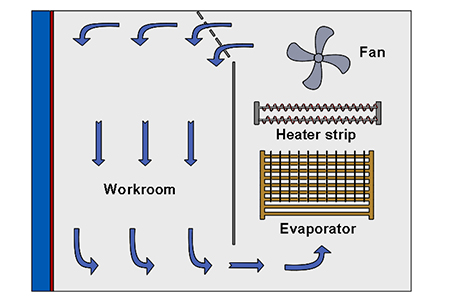

Optimized air circulation structure minimizes local condensation and humidity gradients, improving repeatability between samples and test batches.

4. Data-Oriented Aging Assessment

Stable environmental control allows reliable before/after comparison of mechanical performance, visual appearance, and material integrity.

5. Adaptable Test Logic

Supports constant-condition hydrolysis aging as well as cyclic temperature-humidity profiles to match real service environments.

Structural Highlights of Hydrolysis Aging Test Stability Chamber

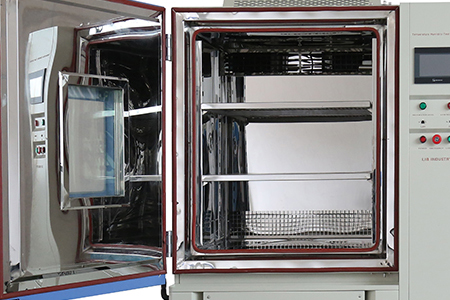

Moisture-Resistant SUS304 Test Workroom | SUS304 stainless steel, selected for its resistance to oxidation, hydrolytic corrosion, and long-term exposure to saturated humidity.

The smooth, non-reactive surface prevents secondary contamination and ensures stable conditions during extended hydrolysis aging tests. Temperature and humidity sensors monitor the test environment in real time, forming a closed-loop PID control system.

|

|

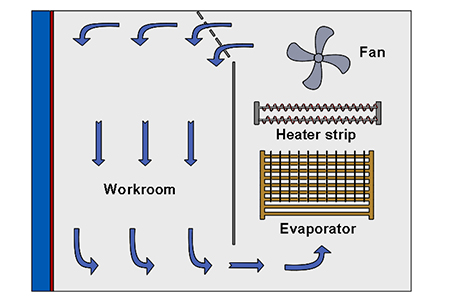

Condensation-Managed Airflow System | |  |

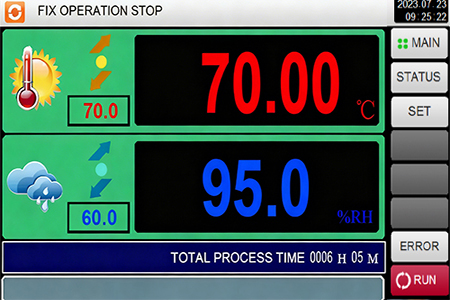

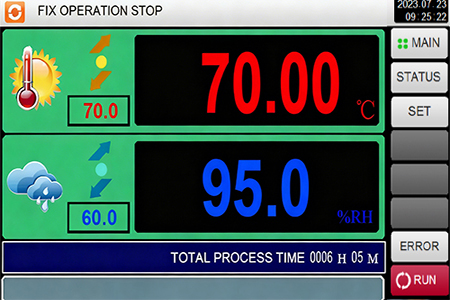

Advanced Programmable Control Platform | The touchscreen controller supports multi-segment test profiles, constant-condition hydrolysis aging, and cyclic temperature-humidity programs.

Test parameters, alarms, and historical data are stored automatically.

|  |

Application-Specific Customization Interfaces | Optional features such as reinforced sample shelves, access ports for mechanical loading or wiring, non-standard chamber dimensions, and viewing windows allow seamless integration into hydrolysis testing workflows. |  |

FAQ – Hydrolysis Aging Test Stability Chamber

Q1: How is hydrolysis aging different from standard damp heat testing?

Hydrolysis aging emphasizes long-term moisture-induced chemical degradation, not short-term humidity resistance. This stability chamber is optimized for extended exposure stability, ensuring results reflect true material aging behavior.

Q2: Can the Hydrolysis Aging Test Stability Chamber be configured specifically for PU hydrolysis standards?

Yes. LIB industry customizes control accuracy, humidity endurance, airflow design, and test programming to match PU and polymer hydrolysis requirements defined by international or internal standards.

Q3: What environmental testing solutions does LIB industry provide beyond this chamber?

LIB industry offers a full range of temperature humidity chambers, fast-rate thermal systems, stability chambers, walk-in chambers, vibration climate chamber, supporting complete environmental testing laboratory construction.

Contact LIB Industry Today

Material hydrolysis failures often appear late and cost more to correct.

A properly engineered Hydrolysis Aging Test Stability Chamber helps identify degradation trends early, with data you can trust.

LIB industry delivers engineered stability systems, flexible customization, and lifecycle-level technical support.

Custom Configurations | 3-Year Warranty | Lifetime Technical Support | Rapid Engineering Response

Contact LIB industry inquiry@libtestchamber.com to configure a chamber aligned with your hydrolysis aging test strategy.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia