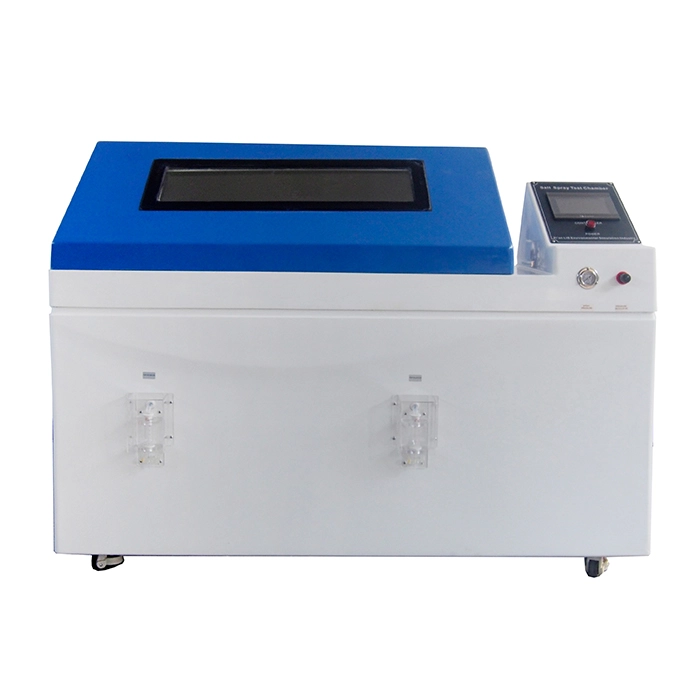

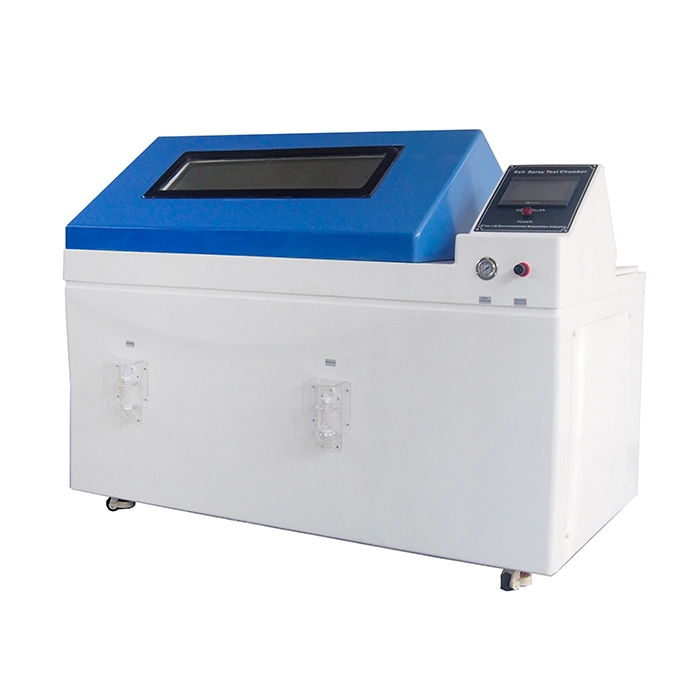

Salt Spray Cabinet Features and Benefits

1. Accelerated and Controlled Corrosion Testing

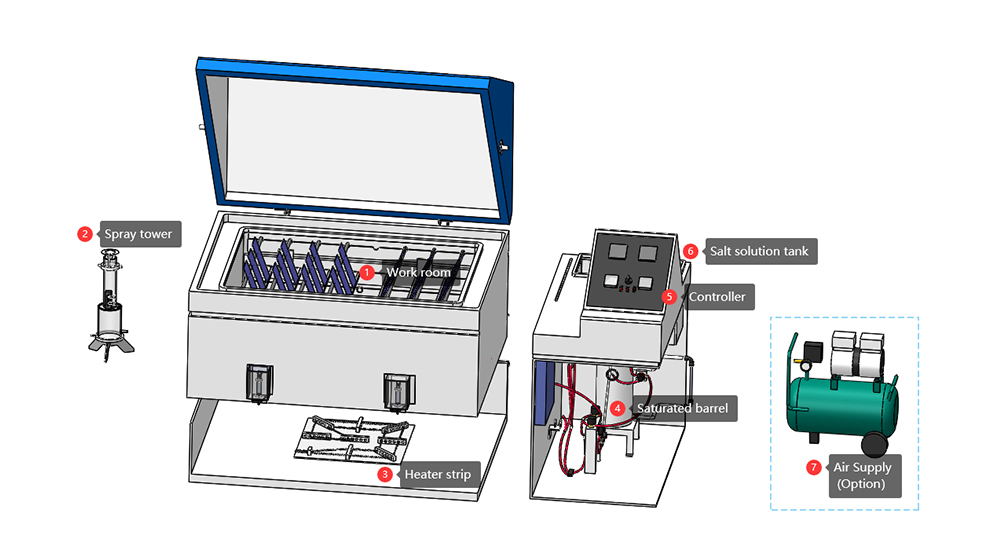

The chamber simulates a marine salt spray environment to accelerate material corrosion, significantly shortening test cycles and improving efficiency. The salt fog is generated under stable conditions with 83 kPa spray pressure and a deposition rate of 1–2 mL/80 cm²·h, fully compliant with ASTM B117 and ISO 9227 standards, ensuring reproducible results across batches.

2. Stable Temperature and Humidity with Precise pH Control

Equipped with PT-100 Class A sensors (±0.001 °C resolution), the chamber maintains temperature within ±0.5 °C and humidity between 95%–98% RH. Salt solution pH is stabilized for NSS (6.5–7.2) and AASS/CASS (3.1–3.3) tests, ensuring highly accurate and repeatable corrosion conditions.

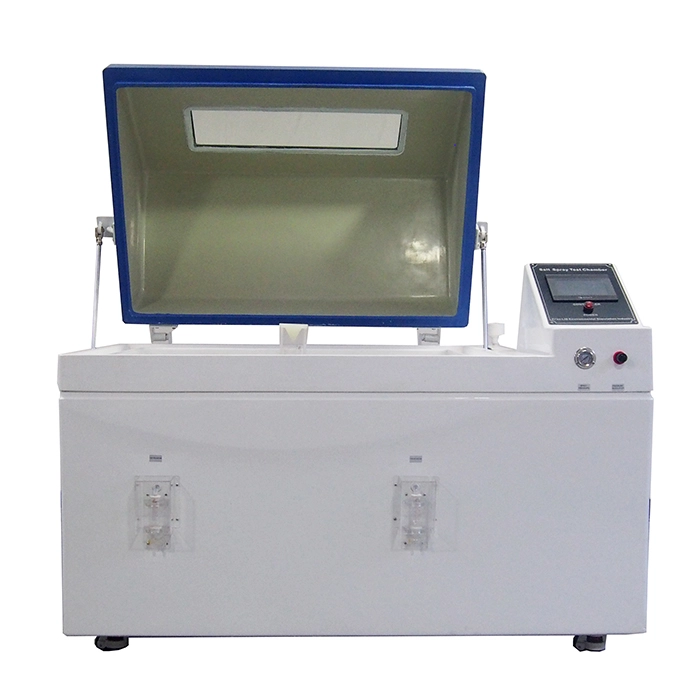

3. Flexible Sample Capacity and Placement

Standard V-groove and round-rod holders allow adjustable sample angles (15°–30°) to prevent shielding effects, enabling multiple samples to be tested simultaneously. The chamber supports a range of model volumes, from small R&D batches to high-throughput production validation.

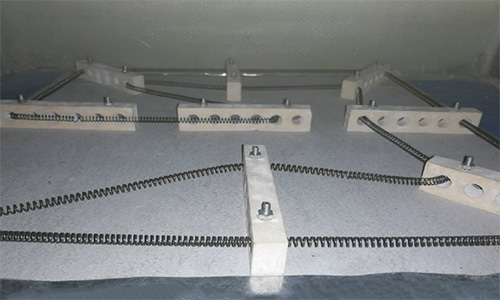

4. Durable Construction for Long-Term Testing

Designed to withstand continuous exposure to salt fog, high temperature, and humidity, the interior remains structurally stable over extended test periods. The inverted-V lid prevents condensate drip, maintaining test validity and reducing maintenance needs.

5. Efficient and Safe Operation

Automated water replenishment, dry-burn protection, and a programmable controller with real-time logging allow safe, unattended operation. Test programs can be fully customized, with continuous or cyclic spray options, while monitoring and alerts ensure safe, reliable operation.

Specifications of Salt Spray Cabinet

Model | S-150 | S-250 | S-750 | S-010 |

Internal dimensions (mm) | 590*470*400 | 1000*640*500 | 1100*750*500 | 1000*1300*600 |

Overall dimensions (mm) | 1460*760*1140 | 1850*960*1350 | 1950*1030*1350 | 2000×1300×1600 |

Interior Volume (L) | 110 | 320 | 410 | 780 |

Temperature Range | Ambient ~ +60 ℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Humidity Range | 95% ~ 98% RH |

Salt Fog Deposition | 1~2ml / 80cm2 · h |

Spray Type | Continuous / Periodic |

Salt Fog Collected | Fog collector and fog measure cylinder |

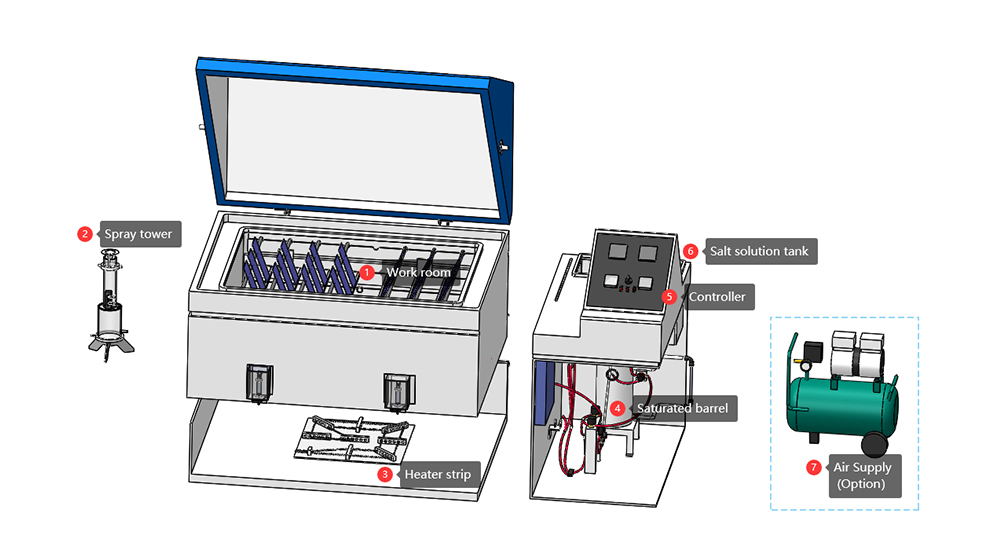

Air Preheating | Saturated air barrel |

Spraying System | Atomizer tower and Spray nozzles |

Controller | PID controller |

Safety Device | Humidifier Dry-combustion Protection; Over-temperature Protection; Over-current Protection; Water Shortage Protection; Earth leakage Protection |

Material | Glass fiber reinforced plastics |

Standard Configuration | 6 round bars and 5 V-shaped grooves |

Configuration of Salt Spray Cabinet

FAQ – Salt Spray Cabinet

Q1: How to prevent salt spray leakage?

A1: To prevent salt spray leakage, our cabinet is made of one-piece fiberglass reinforced plastic, which is sturdy and corrosion-resistant. Additionally, the cabinet features a water-tight sealing trough. Simply fill the trough with water during testing to effectively prevent salt spray from escaping, ensuring a safe and clean testing environment.

Q2: Does the salt spray chamber have an automatic water inlet?

A2: Yes, the cabinet is equipped with an automatic water inlet, which replenishes water as needed based on usage. This ensures stable and continuous operation without frequent manual intervention.

Q3: Can the manual transparent cover be replaced with a pneumatic fiberglass cover?

A3: Yes. The manual transparent cover can be upgraded to a pneumatic fiberglass cover. LIB Industry can customize all non-standard options to meet specific testing requirements.

Ready to Protect Your Products from Corrosion?

Contact LIB Industry Today inquiry@libtestchamber.com to Get Your Customized Salt Spray Testing Solution!

Reliable results, global standards compliance, and fully supported operation.

Warranty: 3-year standard, with lifelong technical guidance.

Rapid Service: Replacement units provided if issues cannot be resolved remotely.

24/7 Support: English-speaking team available worldwide.

Spare Parts: Critical parts stocked internationally, delivery within 7–15 days.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia