Key Features & Advantages of Xenon Weather Resistance Test Chambers

1. Accelerated Outdoor Aging Simulation

High-intensity xenon lamps and controlled environmental settings enable accelerated testing of material weather resistance. Adjustable irradiance ensures reproducible sunlight simulation for different product types, reducing testing time from months to days.

2. Authentic Full-Spectrum Sunlight

Covers 300–800 nm wavelengths, including UV, visible, and IR light. Optional optical filters allow precise simulation of conditions such as daylight, behind-glass exposure, or extended UV scenarios.

3. Versatile Across Industries

Optional optical filters—including Daylight, Window Glass, and Extended UV—allow testing under specific environmental conditions, fully compliant with international standards such as ISO 105-B02, ISO 4892-2, ASTM G155, IEC 60068-2-5, and more.

4. Reliable Measurement & Verification

Integrated UV radiometers with ±5% tolerance, black panel thermometers, and humidity sensors provide accurate, reproducible data.

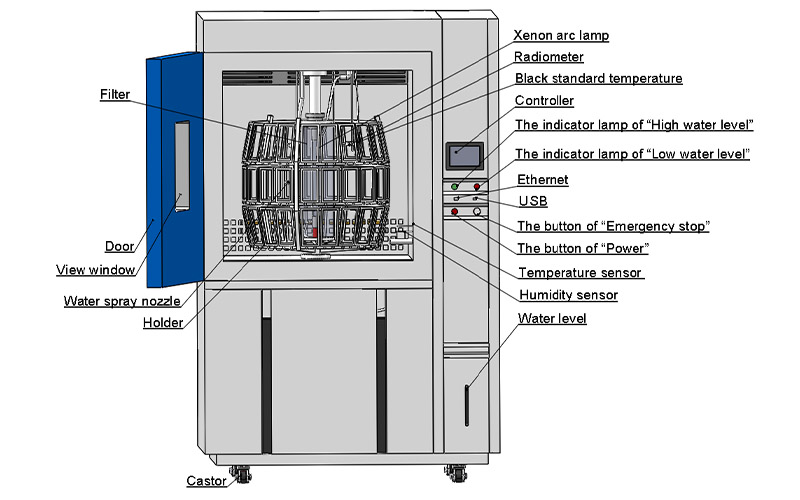

Specifications of Xenon Weather Resistance Test Chamber

Model | XL-S-750 |

Internal Dimension (mm) | 950*950*850 mm |

Overall Dimension (mm) | 1400*1400*1950 mm |

Specimen Holder Size(mm) | 95*200 |

Specimen Capacity | 42pcs |

Chamber Type | Rotating Holder |

Irradiation Source | 1 piece of 4500w water-cooled xenon arc lamp |

Irradiance Range | 35~150 W/㎡ |

Bandwidth Measurement | 300nm~400nm (340nm or 420nm) |

Chamber Temperature Range | Ambient ~ 100 ℃ ±2℃ |

Black Panel Temperature | BPT 35 ~ 85 ℃ ±2℃ |

Humidity Range | 50% ~ 98% RH |

Humidity Deviation | ± 5% RH |

Water Spray Cycle | 1~9999H59M (Adjustable) |

Controller | Programmable color LCD touch screen controller |

Water supply system | Automatic water supply, Water purification system |

Radiometer | UV Radiometer, Tolerance: ±5% |

Cooling System | Mechanical compression refrigeration system |

Product Details of Xenon Weather Resistance Test Chambers

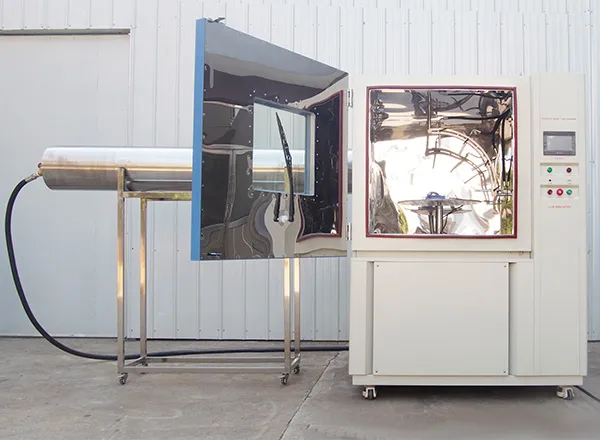

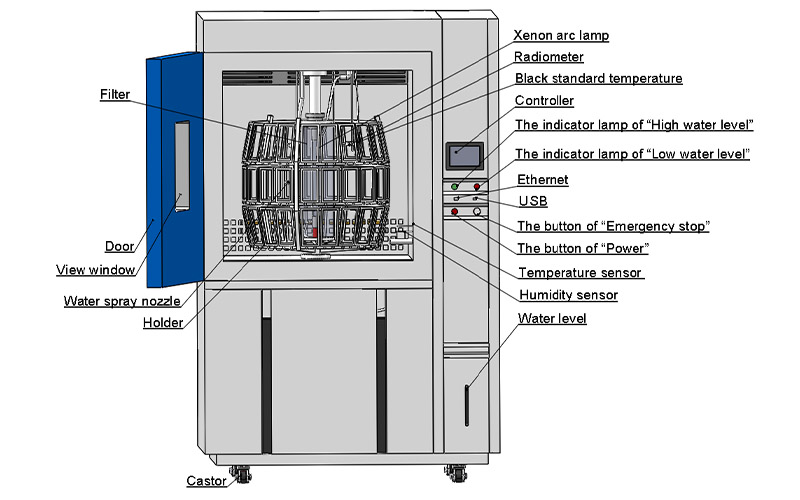

High-Performance Xenon Lamp System | The xenon lamp module adopts a water-cooled 4.5/6.5 kW system engineered for continuous, high-intensity operation. With a uniform spectral output across 300–800 nm, it provides consistent light energy even during extended 1,600-hour test cycles, ensuring test accuracy over long durations while minimizing maintenance intervals.

|

|

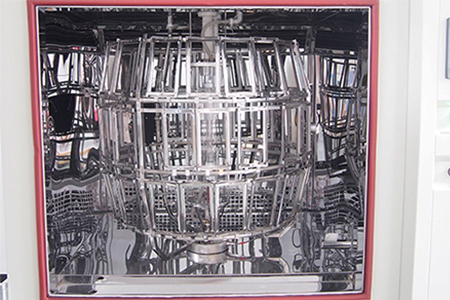

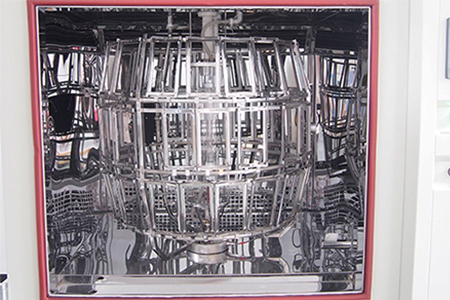

Spacious and Uniform Workroom | Constructed with mirror-finished SUS304 stainless steel, the inner chamber maximizes light reflection and temperature uniformity. The rotating holder exposes each sample to identical radiation angles, preventing shading or uneven fading. A single chamber can accommodate up to 42 pcs of specimen, ideal for high-volume textile or coating tests.

|  |

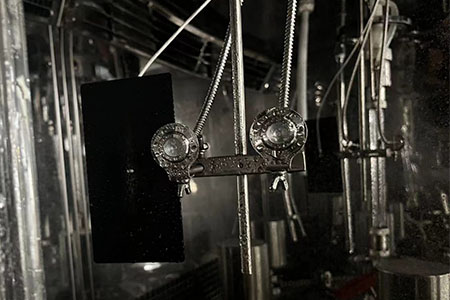

Integrated Spray and Humidity Simulation | Spray manifolds deliver fine mist droplets, simulating natural rainfall or condensation processes. The built-in water purification and recirculation unit reduces water consumption, while automatic drainage prevents scale buildup. Combined with humidity modulation, the system allows realistic wet–dry cycles that mimic actual outdoor aging.

|  |

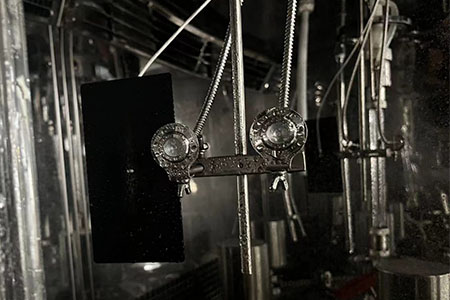

Reliable Measurement and Verification | LIB industry integrates a UV radiometer and black-panel thermometer calibrated to ISO standards, capturing every fluctuation in irradiance and surface temperature. Data accuracy is maintained within ±5% deviation, and all measurements are continuously logged by the controller.

|  |

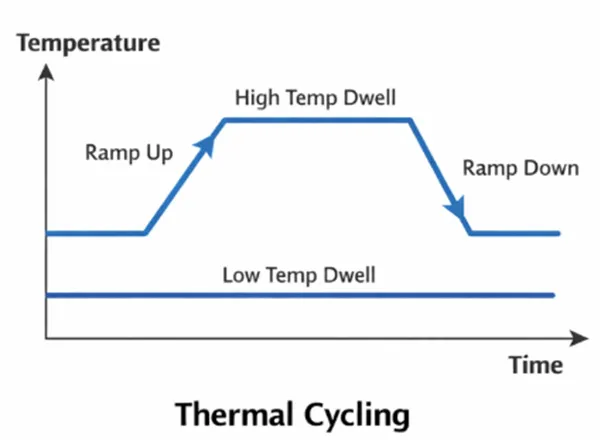

Intelligent Controller & Data Management | Color LCD touchscreen PLC controller supports fully programmable test profiles, multi-language operation, and USB/Ethernet data export. Real-time monitoring of temperature, humidity, and irradiance ensures traceable results.

|  |

Contact LIB Industry for Your Weather Resistance Solution

Accelerate your product development and quality assurance with LIB industry Xenon Weather Resistance Test Chambers. Contact our team today inquiry@libtestchamber.com to discuss customized configurations, obtain detailed technical specifications, and schedule a live demonstration within 1~3 hours. 3-year extended warranty, lifetime service, 5 major service centers worldwide—trust LIB industry for precise, reliable, and fast results.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia