SAE J2020 defines how to run fluorescent UV + condensation exposures for automotive exterior materials. It focuses on the damage mechanisms that dominate outdoors—UV photo‑degradation, moisture/condensation, and thermal cycling—while keeping the test simple, repeatable, and fast. A commonly used automotive cycle is UV (day) + condensation (night), which accelerates gloss loss, color shift, embrittlement and crack initiation compared with natural weathering.

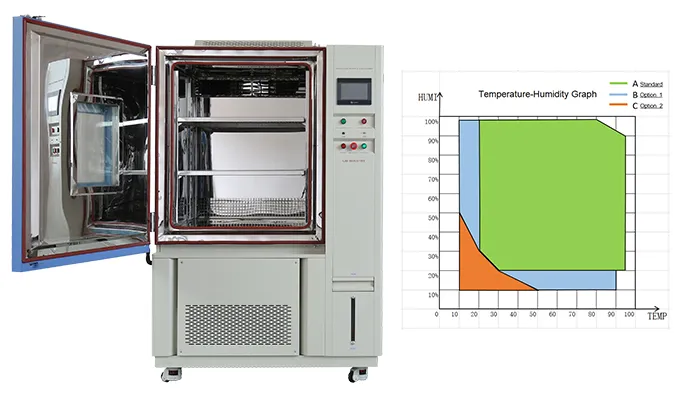

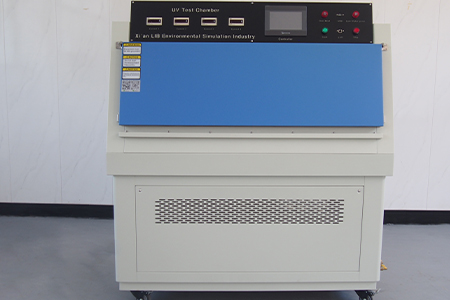

The LIB UV Light Accelerated Weathering Tester

Meet LIB UV Light Accelerated Weathering Tester – Model UV‑SI‑260 . It is engineered around the J2020 workflow and also covers ASTM G154/G151, ASTM D4329/D4587, ISO 4892-3, EN 1297, IEC 60068-2-5, giving you one platform for both automotive and general polymer/coating programs.

What you’ll notice in daily use

- Three-phase weathering: UV irradiation → condensation → optional water spray (for thermal shock/erosion).

- Lamp flexibility: UVA‑340 (natural solar UV match) or UVB‑313 (harsher, screening) — eight 40 W fluorescent tubes.

- Tight control: Irradiance 0.3–20 W/m² (controller feedback), BPT 35–80 °C, chamber temperature ambient–90 °C (±2 °C), RH ≥95% in condensation.

- Capacity & throughput: 56 standard panels (75×150 mm) at 50 mm from lamps for uniformity; custom 3D fixtures available.

- Operator experience: Color LCD touchscreen, programmable recipes, Ethernet/USB for remote monitoring and data export.

- Water system: Automatic feed + purification for clean, repeatable condensation and spray.

- Safety: Over‑temperature/current, water‑shortage, earth‑leakage, and phase‑sequence protections.

A field‑ready SAE J2020 program

1) Choose the lamp set:

- Start with UVA‑340 for the best match to outdoor solar UV on clear days; use UVB‑313 when you need a more severe screen or per OEM spec.

2) Load & mount:

- Up to 56 flat coupons (75×150 mm) or fixtures for molded parts. Keep the 50 mm lamp distance; mix panel positions between runs to average any gradient.

3) Program the cycle:

- Create a repeating 12‑hour block: 8 h UV (day) at a BPT typically 60–70 °C → 4 h condensation (night) at ~50 °C BPT. (Adjust to your drawing/spec; many automotive specs reference this pattern.)

- Set irradiance to the value called out by your OEM/material spec; the controller maintains it automatically within the 0.3–20 W/m² band.

- Enable spray steps only if the method/spec calls for it (use short bursts to avoid over‑cooling unless thermal shock is desired).

4) Monitor & log:

- Log irradiance, BPT, and condensation runtime. Export via Ethernet/USB for your LIMS. Check the water quality and black panel cleanliness weekly.

5) Scale duration to the question:

- Screening: 200–400 h; Qualification: 500–1000 h or as specified; Correlation: align with your natural‑exposure delta‑E/gloss targets.

What makes LIB’s implementation different

- Uniformity first: Parallel lamp layout and 50 mm geometry designed for even irradiance across all slots; capacity without hot‑spotting.

- Recipe portability: Build a method once, save it, and email/export the file to mirror across sites or suppliers.

- Serviceability: Lamps are quick‑swap (≈1600 h life); wear parts are off‑the‑shelf; remote diagnostics via Ethernet.

- Global compliance: One chamber covers your automotive (SAE J2020) and general polymer/coatings (ASTM/ISO) methods.

FAQ — quick hits

Q: UVA‑340 or UVB‑313?

Start with UVA‑340 for correlation to natural sunlight; use UVB‑313 only if your spec requires a more severe spectrum or for fast screening.

Q: How many hours equal one year outdoors?

There’s no single multiplier—correlate against your field site and failure mode. Use natural exposure data to set your target ΔE/gloss loss, then back‑calculate an hours‑to‑target for your material.

Q: Do I need water spray if J2020 is UV+condensation?

Use spray selectively for erosion or thermal shock studies; standard J2020 cycles rely on condensation for moisture.

Ask LIB for the UV‑SI‑260 application note + quote or share your current spec—we’ll map it to a turnkey recipe and capacity plan.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia