Based on ASTM G155-13 and ISO 4892-3 / ASTM D4329

Biodegradable trays, films, and straws are increasingly used in food packaging and disposable consumer products. While these materials offer clear environmental advantages, they are also more sensitive to light exposure, temperature variation, and humidity during storage and distribution.

As a result, shelf life testing has become a critical step to verify that biodegradable products can maintain their mechanical strength, appearance, and functionality throughout their intended service life.

International accelerated aging standards such as ASTM G155-13, ISO 4892-3, and ASTM D4329 provide scientifically validated methods to evaluate durability under controlled laboratory conditions. When these standards are implemented using xenon arc chambers and UV test chambers, manufacturers can generate reliable shelf life data that closely reflects real-world exposure.

|  |

Xenon Arc Chamber | UV Test Chamber |

Shelf life for biodegradable materials does not describe how fast a product decomposes in composting conditions. Instead, it defines how long the product remains fit for use during storage, transportation, and shelf display.

For biodegradable trays, films, and straws, the primary degradation drivers include:

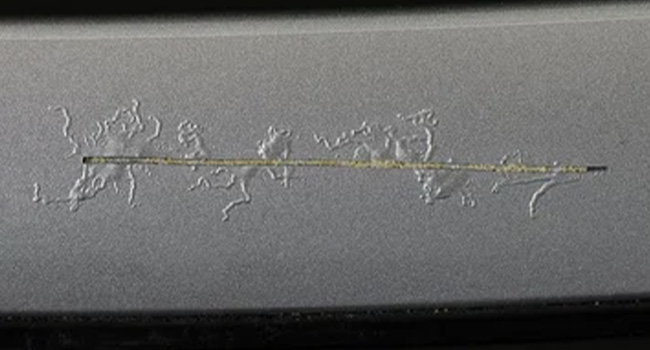

UV and visible light, causing photo-oxidation and molecular chain scission

Elevated temperature, accelerating oxidation and thermal aging

Humidity and condensation, promoting hydrolysis in ester-based polymers such as PLA, PBAT, and PBS

In real environments, these factors do not act independently. They interact simultaneously, which is why single-factor aging tests are insufficient. Xenon and UV accelerated weathering tests reproduce these combined stresses in a controlled and repeatable manner, making them essential tools for shelf life evaluation.

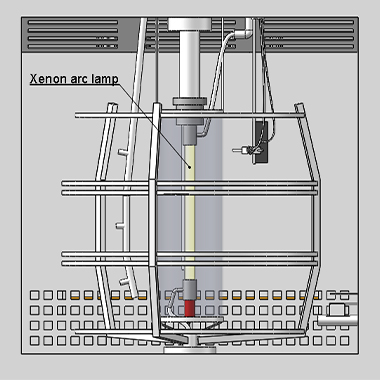

ASTM G155-13 specifies accelerated weathering using full-spectrum xenon arc light combined with controlled temperature and humidity. The xenon light source closely matches natural sunlight across the UV, visible, and infrared ranges, allowing realistic simulation of outdoor and shelf exposure conditions.

Unlike UV-only methods, this approach evaluates photo-oxidation, thermal aging, and moisture-driven degradation simultaneously, which is especially important for biodegradable materials whose aging behavior is strongly influenced by heat and humidity.

In practical shelf life testing of biodegradable trays and molded products, the following parameters are commonly applied in accordance with ASTM G155-13:

Light source:

Full-spectrum xenon arc lamp

Irradiance control:

0.35 W/m² @ 340 nm (widely used for polymer durability and shelf life studies)

Black panel temperature:

63 ± 3 °C to simulate surface heat accumulation

Chamber air temperature:

38–45 °C, representing storage and transportation environments

Humidity / moisture exposure:

50–95% RH or programmed humidity / spray cycles

Exposure duration:

Typically 500–2000 hours, depending on target shelf life correlation

These parameters allow accelerated aging while maintaining a realistic degradation mechanism, which is critical for defensible shelf life claims.

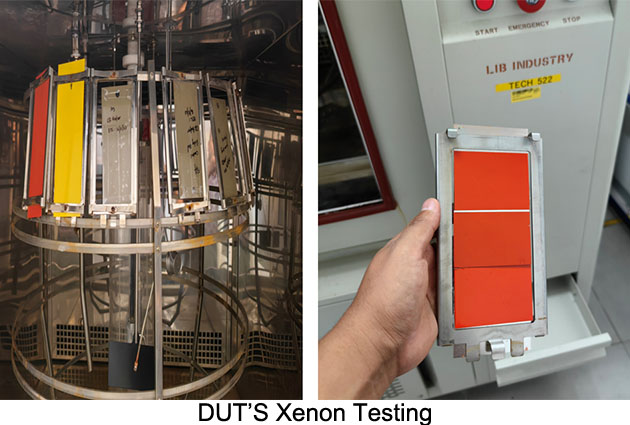

LIB industry xenon test chamber allows:

Uniform full-spectrum light exposure and closed-loop irradiance control

Stable temperature and humidity control for long-duration testing

Multi-cycle programming aligned with ASTM G155 exposure methods

Customizable specimen holders suitable for trays, straws, and assembled products

Model | XL-S-750 |

Chamber Type | Rotating Holder |

Irradiation Source | 1 piece of 4500w water-cooled xenon arc lamp |

Irradiance Range | 35~150 W/㎡ |

Bandwidth Measurement | 300nm~400nm (340nm or 420nm) |

Chamber Temperature Range | Ambient ~ 100 ℃ ±2℃ |

Black Panel Temperature | BPT 35 ~ 85 ℃ ±2℃ |

Humidity Range | 50% ~ 98% RH |

Water Spray Cycle | 1~9999H59M (Adjustable) |

| .jpg) |

LIB industry xenon test chambers with closed-loop irradiance control, precise thermal and humidity regulation, and customizable specimen fixtures for trays, straws, and assembled products,which ensures that shelf life testing results are both repeatable and representative of real-world conditions.

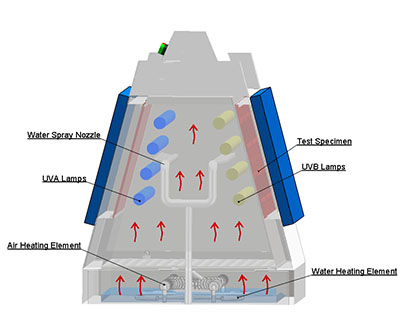

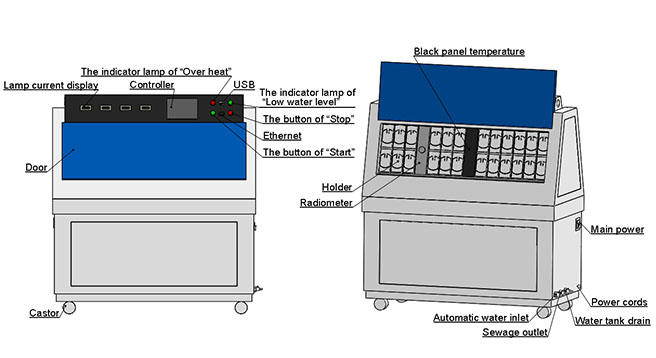

ISO 4892-3 and ASTM D4329 define accelerated aging methods using fluorescent UV lamps to evaluate material resistance to UV-induced degradation. These standards focus on controlled UV exposure combined with condensation cycles to simulate dew and moisture effects.

This approach emphasizes UV-driven photo-degradation, making it highly effective for thin biodegradable products where UV penetration is the dominant aging factor.

For biodegradable films and straws, commonly applied test conditions include:

Lamp type:

UVA-340 lamps, providing a close match to the UV portion of natural sunlight

UV irradiance:

0.68–0.89 W/m² @ 340 nm

UV exposure cycle:

8 hours UV exposure at 60 °C

Condensation cycle:

4 hours condensation at 50 °C

Total exposure duration:

300–1000 hours for comparative shelf life evaluation

These parameters enable rapid differentiation of material formulations while maintaining consistency with ISO and ASTM requirements.

Biodegradable films and straws typically have thin cross-sections, making them highly sensitive to UV radiation. UV fluorescent testing is particularly effective for evaluating:

High-Acceleration UV Exposure

Precise and Repeatable UV Irradiance Control

Integrated Condensation and Moisture Simulation

Excellent Suitability for Thin and Flexible Materials

Model | UV-SI-260 |

Specimen Capacity | 56 Pieces |

Irradiation Source | Fluorescent UV lamps (8) - 40 W |

Temperature Range | Ambient ~ 90 ℃ ±2℃ |

Black Panel Temperature (BPT) | 35 ~ 80 ℃ |

Humidity Range | ≥95% RH |

Bandwidth | 290 ~ 400nm |

Irradiance Control | 0.3~20 W/㎡ |

| Water Spray Cycle | 1~9999H59M (Adjustable) |

|  |

LIB industry UV test chambers provide stable UV irradiance control, automated condensation systems, and programmable exposure cycles to ensure full compliance with ISO 4892-3 and ASTM D4329.

Biodegradable Product Type | Recommended Test Standard | Test Equipment Selection | Primary Evaluation Focus |

Biodegradable Trays | ASTM G155-13 | Xenon test chamber | Warping resistance, load-bearing capacity, surface degradation under combined light, heat, and humidity |

Biodegradable Films | ISO 4892-3 / ASTM D4329 | UV test chamber | Tensile strength retention, elongation at break, color stability and yellowing |

Biodegradable Straws | UV: ISO 4892-3 / ASTM D4329 (screening)Xenon: ASTM G155-13 (validation) ASTM G155-13 + humidity | UV test chamber + Xenon test chamber | Early-stage embrittlement, surface cracking, functional integrity under realistic exposure |

Many manufacturers adopt a combined xenon + UV testing approach, using UV testing for rapid screening and xenon testing for final shelf life validation under realistic environmental conditions.

Shelf life assessment should be based on functional performance rather than exposure time alone. Typical evaluation indicators include:

Mechanical property retention (tensile strength, elongation, impact resistance)

Dimensional stability and warping

Color change (ΔE) and surface appearance

Cracking, embrittlement, or loss of flexibility

These indicators provide quantitative support for shelf life labeling and technical documentation.

Effective shelf life testing for biodegradable trays, films, and straws requires more than simple UV exposure. By applying ASTM G155-13 with xenon test chambers and ISO 4892-3 / ASTM D4329 with UV test chambers, manufacturers can accurately evaluate durability under combined light, temperature, and humidity conditions.

Contact LIB industry inquiry@libtestchamber.com to receive a customized shelf life testing plan and compliant xenon or UV testing solution within 1~3 hours for biodegradable packaging materials.

Custom Configurations | 3-Year Warranty | Lifetime Technical Support

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia