In harsh desert and industrial environments, failure rarely happens all at once.

It starts with dust infiltration, escalates to sand erosion, and ends in system malfunction or premature field failure.

For aerospace, defense, and ruggedized industrial products, a single failure in sand and dust qualification can mean:

Redesign and retesting delays

Missed delivery schedules

Rejected audits or customer acceptance failures

Significant cost overruns across the project lifecycle

This is why MIL-STD-810H Method 510 has become a critical environmental qualification requirement for products expected to operate in airborne particulate environments.

But passing Method 510 is not simply about “running a test.”

It requires precise control of airflow, particle behavior, and test repeatability—areas where many test systems fall short.

MIL-STD-810H Method 510 evaluates equipment resistance to airborne particulates through two fundamentally different test procedures, each imposing unique engineering demands on test equipment.

Blowing dust testing focuses on fine particulate penetration.

Its objective is to assess how dust affects:

Seals and gaskets

Ventilation openings and filters

Electrical insulation and circuit boards

Key technical requirements include:

Dust particle size below 150 μm

Controlled dust concentration, typically 10.7 ± 7 g/m³

Stable airflow that keeps dust suspended without excessive turbulence

Even minor fluctuations in concentration or airflow can invalidate test results.

Blowing sand testing is an entirely different challenge.

Instead of infiltration, the focus shifts to physical erosion and mechanical damage caused by larger particles moving at high speed.

Key requirements include:

Sand particle size ranging from 149 μm to 850 μm

High airflow velocity, up to 29.0 m/s

Uniform sand distribution across the test volume

This procedure places extreme stress on airflow systems, chamber materials, and safety mechanisms.

Many laboratories discover too late that not all sand and dust test chambers are created equal. Common failure points include:

Unstable or non-uniform airflow, leading to inconsistent erosion patterns

Dust concentration drift during long-duration tests

Systems designed for dust only, unable to sustain high-speed sand erosion

Insufficient safety protection during high-velocity blowing sand tests

These shortcomings often result in non-repeatable data, failed audits, or the need to rerun costly qualification programs.

The DIM-1000 MIL-STD-810H Blowing Sand Dust Test Chamber is engineered as a dedicated Method 510 solution, not an adapted dust system.

Model | DIM-1000 |

Overall Dimension | 2800*3500*2000mm D*W*H |

Interior Volume | 1000L |

Blowing Dust | |

Air velocity | 1.5 -8.9m/s |

Concentration of dust | 10.7±7g/ m³ |

Dust particles | < 150μm |

Blowing sand | |

Air velocity | 18.0 -29.0m/s |

Concentration of sand | 0.18+0.2g/m³; 1.1+0.3g/m³; 2.2+0.5g/m³ |

Sand particles | 149μm - 600μm, 600μm - 850μm |

Controller | Programmable color LCD touch screen controller |

Door Lock | Electromagnetic lock |

Testing Platform Diameter | 600mm |

Testing Platform Speed | 1-7 r.p.m |

Dust Detector | Integrated dust detector |

Exterior Material | A3 Steel Plate with protective coating |

Interior Material | SUS304 stainless steel |

Maximum Noise | 65 dBA |

|  |

| Workroom | Large Centrifugal Fan |

| |

A single DIM-1000 chamber supports:

Blowing Dust: particle size < 150 μm

Blowing Sand: particle size 149–850 μm

Adjustable air velocity from 1.5 to 29.0 m/s

This dual capability eliminates the need for separate systems and simplifies laboratory workflows.

To ensure test validity and repeatability, the DIM-1000 integrates:

Real-time dust concentration monitoring with closed-loop control

Optimized airflow duct design for uniform particle distribution

Stable wind speed control across the entire test duration

These features ensure compliance with the strict tolerances defined by MIL-STD-810H.

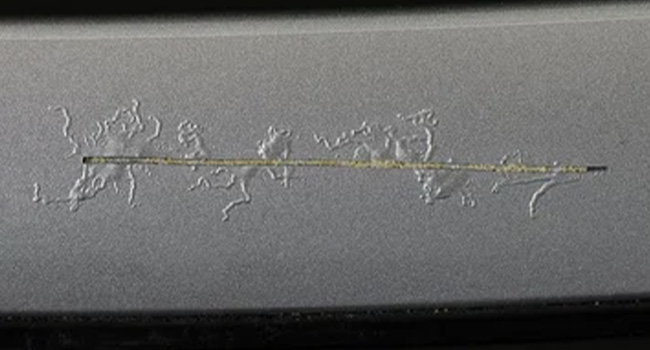

Blowing sand tests are inherently abrasive. The DIM-1000 addresses this with:

SUS304 stainless steel inner chamber, resistant to sand erosion

Reinforced airflow channels designed for high-speed particulate flow

Durable structural components engineered for long service life

This construction ensures consistent performance even under repeated, high-stress testing conditions.

Modern qualification testing demands traceability. The DIM-1000 provides:

Programmable color LCD touch screen control

Ethernet connectivity for remote monitoring

Test data recording and export for audit documentation

These capabilities simplify compliance verification for aerospace and defense programs.

High-speed sand testing introduces operational risks.

The DIM-1000 incorporates electromagnetic door locking, preventing accidental access during testing and ensuring operator safety.

A: Yes. For MIL-STD-810H Method 510 Procedure II, airflow velocity is not just a peak value—it must be stable, measurable, and repeatable throughout the test duration.

The DIM-1000 blowing sand dust test chamber is engineered with a reinforced high-power airflow system capable of delivering adjustable wind speeds from 1.5 to 29.0 m/s, ensuring full compliance with the erosion requirements of blowing sand tests.

A: Uniform exposure is critical for reliable qualification results. The DIM-1000 is equipped with a 600 mm diameter rotating testing platform, allowing samples to be exposed to sand and dust from all directions (360°).

This design prevents shadowing effects and uneven erosion, especially for complex assemblies and enclosures with vents, seams, and seals.

A:

Absolutely. The DIM-1000 series is supplied with:

CE certification for electrical and mechanical safety

A complete MIL-STD-810H Method 510 technical datasheet, clearly detailing:

Particle size ranges

Air velocity performance

Dust concentration control

Test volume and load capacity

These documents are essential for audit reviews, qualification reports, and customer acceptance in aerospace and defense projects.

A: Maintaining a stable dust concentration is one of the most challenging aspects of Method 510 testing. The DIM-1000 integrates a real-time dust concentration monitoring system, which continuously measures and regulates dust levels throughout the test cycle.

This closed-loop control prevents concentration drift and ensures the test remains within the specified tolerance defined by MIL-STD-810H.

A: Yes. Beyond equipment delivery, the DIM-1000 solution includes professional commissioning support, either on-site or remotely, depending on project requirements.

Experienced engineers assist with:

Initial installation and calibration

Test profile setup for Method 510

Operator training and troubleshooting

This ensures the chamber delivers valid and repeatable results from day one, minimizing downtime and project risk.

A: Unlike systems adapted from dust-only designs, the DIM-1000 is purpose-built to support both Procedure I (Blowing Dust) and Procedure II (Blowing Sand) within a single test chamber.

This dual capability helps laboratories and manufacturers:

Reduce capital investment

Save valuable lab space

Simplify maintenance and operator training

LIB industry backs your MIL-STD-810H blowing sand and dust test chamber with a 3-year warranty and lifelong technical support. Our 24/7 English-speaking service team, globally stocked spare parts, and professional commissioning support ensure reliable operation and minimal downtime throughout your qualification project.

Request a Quote or Obtain the Technical Datasheet inquiry@libtestchamber.com

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia