Today, with the rapid popularization of intelligent and miniaturized electronic devices, products need to undergo strict environmental stress tests before leaving the factory to ensure stable performance under different temperature and humidity conditions.

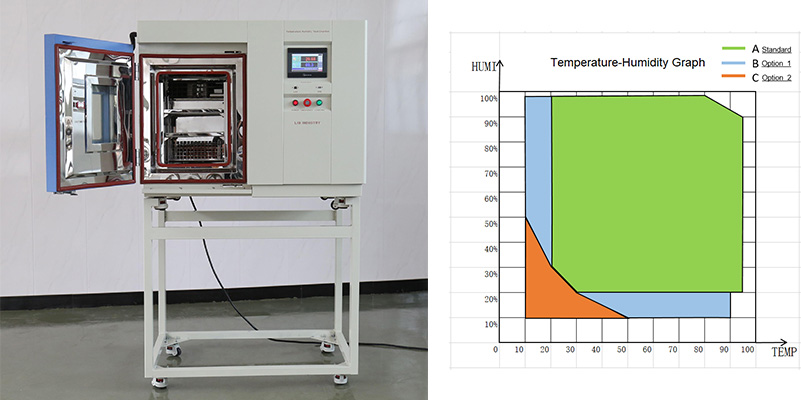

The benchtop temperature humidity chamber, with its advantages of small footprint, precise control and flexible operation, has become an ideal tool for testing in the field of precision electronics.

Electronic components such as IC chips, PCBS, sensors, optical modules, etc. are particularly sensitive to environmental changes. The rise and fall of temperature and humidity may lead to uneven expansion of materials, fatigue of solder joints, moisture absorption and expansion of components, and even leakage failure. For this reason, environmental test chambers are commonly used in laboratories to simulate real working conditions and test the reliability of product designs.

Temperature Cycling Test:

Simulate the repeated temperature differences in different environments such as day and night, indoor and outdoor.

Constant Temperature and Humidity Testing:

Long-term verification of the aging and corrosion of components under high temperature and high humidity conditions.

Rapid Temperature Change Test:

Coping with rapid environmental changes such as transportation and startup.

Wet and heat alternating test:

Verify the sealing performance and insulation tolerance.

Compared with large environmental rooms, the advantages of desktop equipment are obvious:

Suitable for desktop experiments, saving laboratory space;

Temperature fluctuation ±0.3°C, humidity fluctuation ±2.5%RH;

Suitable for coexistence of office and research and development Spaces;

Supports program setting, multi-segment loop operation and remote control.

LIB's benchtop temperature humidity test chambers are widely used in university laboratories, semiconductor enterprises and electronic manufacturers, providing strong support for the reliability testing of precision components.

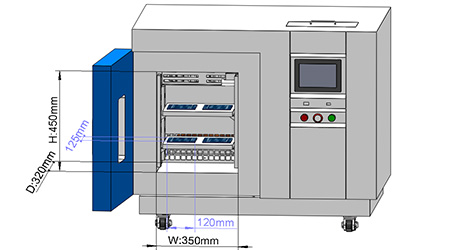

Model | TH-50 | TH-80 |

Internal Dimension (mm) | 320*350*450 | 400*400*500 |

Overall Dimension (mm) | 820*1160*950 | 900*1210*1000 |

Interior Volume | 50L | 80L |

Temperature Range | A : -20℃ ~ +150 ℃ B : -40℃ ~ +150 ℃ C: -70℃ ~ +150 ℃ | |

Temperature Fluctuation | ± 0.5 ℃ | |

Humidity Range | 20% ~ 98% RH | |

Cooling Rate | 1 ℃ / min | |

Heating Rate | 3 ℃ / min | |

Controller | Programmable color LCD touch screen controller Ethernet connection | |

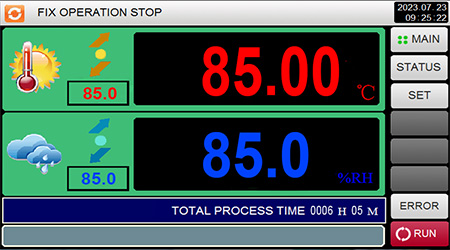

The following is a typical test process of an IC chip in a LIB desktop temperature and humidity chamber:

Verify the functional stability and packaging sealing performance of the chip in a high-temperature and high-humidity environment.

Prepare the test samples

Install the IC chip on the test circuit board and connect it to the functional test interface; When necessary, install temperature and humidity sensors to monitor the surface parameters of the samples.

Equipment Settings

Set the test conditions on the LIB controller interface:

Temperature: 85°C

Humidity: 85%RH

Test duration: 96 hours

Operation mode: Constant temperature and humidity + periodic data recording

Sample placement and wiring

Fix the test circuit board on the sample rack and connect it to the external functional tester through the back lead wire to ensure that the door seal is not affected.

Start the program and monitor the data

After starting the test program, the device will continuously record the temperature and humidity data inside the chamber. The external functional tester detects in real time whether the operating voltage, current and data output of the chip are stable.

Test completion and analysis

After 96 hours, the test is completed. The chip is removed for functional retesting and visual inspection to confirm whether there are any abnormalities such as solder joint oxidation, package cracking, or leakage.

Evaluation Result:

If the chip shows no performance fluctuation throughout the entire testing process and passes the functional test, it can be determined that it meets the reliability requirement of 85℃/85%RH. The built-in USB interface of the LIB device can export the temperature and humidity curves and test logs, which are used for report preparation and quality review.

Use LIB equipment for stress verification of multi-layer board soldering;

Test the response performance of products in the dry and cold climate of the north and the hot and humid climate of the south;

Study the trend of electrical performance degradation of new materials in high-humidity environments.

The LIB benchtop environmental chamber, with its stable performance and precise control, helps global scientific research and industrial users improve product quality and optimize design verification processes. LIB promises that all products enjoy a 36-month extended warranty and lifetime service. A 24/7 professional English after-sales team will solve any problems you encounter during testing. LIB will safeguard your testing.

If you have any relevant testing requirements, please leave your requirement information below. LIB will respond to your requirements within 24 hours and provide a competitive quotation and professional solution.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia_20251204110329.webp)