From smartphones and wearable electronics to underwater lighting and industrial sensors, ip waterproof performance has become a decisive purchasing factor. Among all protection ratings, IP68 is widely perceived as the highest and most reliable symbol of durability.

Yet in real markets, failures are common.

Products labeled IP68 leak, corrode, or malfunction after exposure to real-world water conditions. In most cases, the root cause is not manufacturing defects, but a fundamental misunderstanding of the IP68 definition and its validation logic.

From the perspective of an environmental testing laboratory, this article explains:

What IP68 actually means

Why IPX8 is not a fixed standard

And how true IP68 validation depends on laboratory capability, not labels

IP (Ingress Protection) is an international classification system that evaluates two independent protection mechanisms:

Solid particle ingress protection

Liquid ingress protection

Each digit represents a completely different test philosophy, performed independently.

The first digit “6” corresponds to IP6X, the highest dust protection level:

Completely dust-tight

No ingress of fine particles under defined conditions

Importantly:

Passing IPX8 alone does not qualify a product for IP68

Long-term water resistance is meaningless without proven dust-tight integrity

Dust intrusion accelerates seal wear, compromises O-rings, and dramatically reduces long-term water resistance.

| Rating | Test Condition |

|---|---|

| IPX7 | 1 m water depth, 30 minutes (fixed) |

| IPX8 | Depth, duration, and conditions defined by manufacturer |

IPX8 is not a single test.

It is an agreement-based rating that must reflect real application environments.

“Deeper than 1 meter = IPX8” → Incorrect

ATM pressure ≠ static laboratory water pressure

Short-term immersion ≠ stable water resistance rating

Without controlled pressure, time, and data traceability, IPX8 claims lack credibility.

Under long-term pressure:

O-rings deform

Stress relaxation occurs

Micro-leakage develops gradually

Failures often appear hours or days, not minutes, after immersion begins.

Conventional water tanks fail because:

Pressure is uncontrolled

Depth is not repeatable

No continuous data logging exists

This leads to false pass results and unreliable IP waterproof claims.

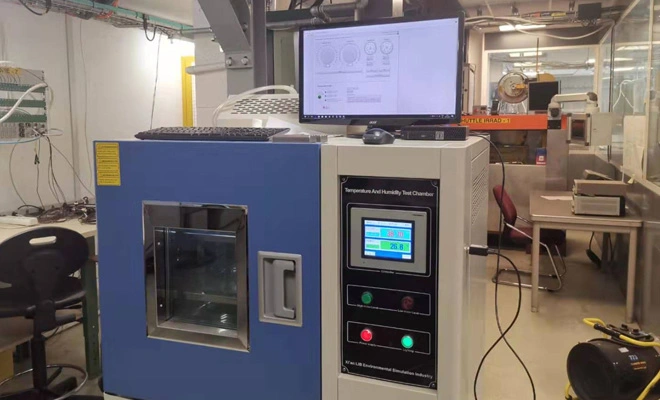

At the laboratory level, IP68 requires two fully independent but coordinated systems.

Fully enclosed dust circulation

Negative pressure control to simulate suction effects

Controlled dust concentration and deposition

Repeatable and auditable test conditions

|  | |||

| ||||

Model | DI-800 | DI-1000 | DI-1500 | DI-2000 |

Useful Volume (L) | 800 | 1000 | 1500 | 2000 |

Temperature Range | Ambient ~ +50℃ | |||

Humidity Range | < 30% RH | |||

Normal Wire Diameter | 50um | |||

Nominal Width of a Gap Between wires | 75um | |||

Specimen Power Outlet | Dust-proof socket 16A | |||

Controller | Programmable color LCD touch screen controller, Ethernet connection | |||

Interior Material | SUS304 stainless steel | |||

Standard Configuration | Sample shelf, dust wiper, talcum powder(5kgs) | |||

Precision hydrostatic pressure control

Customizable depth simulation:

10 m / 50 m / 100 m

0.1 MPa – 1 MPa+

Long-duration stability: 24 h, 72 h, or longer

Continuous pressure and time monitoring

| |

Model | R78-600 |

Internal Dimension (mm) | Diameter 600mm * Height 1500 mm |

Overall Dimension (mm) | Diameter 800mm * Height 1800 mm |

Pressure | 50m water depth pressure |

Open mode | Pneumatic lid |

Material | A3 steel plate, wall thickness 15mm |

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Water Supply System | Storage water tank, Automatic water supply |

|  |

| Test Area | Footstand |

|  |

| Control Panel | Safety Lock |

This system verifies whether the water resistance rating remains stable under sustained deep-water pressure.

LIB industry designs IP waterproof solutions from a verification-first philosophy:

High pressure stability minimizes false results

Full test curves are recorded and traceable

IPX8 conditions are customized to real application scenarios, not generic templates

High-strength pressure vessel design

Thickened stainless steel construction

Explosion-proof viewing windows

Multi-level safety interlocks

One-click depth and time configuration

Automatic curve generation and reporting

Reduced operator error and higher repeatability

Optional temperature and humidity coupling

More realistic ip waterproof validation under combined stress conditions

IP68 is not a logo.

It is a verifiable, repeatable, auditable laboratory capability.

Without a complete testing system, IP68 remains a marketing assumption.

LIB industry helps manufacturers transform IP68 from a claim into a proven water resistance rating.

Yes. LIB industry delivers full turnkey IP laboratories, including:

IP dust and water ingress systems

Integrated layouts for combined testing

Customized solutions based on your product and standards

Supported solutions include:

Various no-enclosure water spray and rain simulation systems

From individual equipment to a complete qualification lab, LIB industry supports the entire validation chain.

Absolutely.

To protect your long-term investment, LIB industry backs every test system with:

3-year warranty

Lifelong technical support

24/7 English-speaking service team

Globally stocked spare parts

Professional installation and commissioning support

This ensures stable operation and minimal downtime throughout your qualification projects.

Yes. IPX8 is an application-driven rating.

LIB industry customizes:

Water depth

Pressure level

Test duration

Safety margins

All parameters are aligned with your real-use environment, not generic assumptions.

Yes. LIB industry systems are designed for sequential and integrated IP testing, ensuring:

IP6X dust validation

Followed by IPX8 deep-water testing

Unified reporting and traceability

If you are:

Redefining your IPX8 rating

Upgrading ip waterproof testing capability

Or ensuring your IP68 products survive real-world validation

LIB industry provides complete IP68 laboratory solutions.

Get access to:

IP6X dust test chamber specifications

IPX8 pressure water test chambers (10–100 m customizable)

Application-based IP68 test strategy recommendations

Contact LIB industry environmental testing engineers today inquiry@libtestchamber.com and turn IP68 from a marketing label into a data-backed quality guarantee.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia