Why Manufacturers Choose ASTM G151 G155 Xenon Light Radiation Exposure Test Machine

1️⃣ Full-Spectrum Solar Replication for Multiple Industries

The xenon radiation system reproduces global sunlight spectra critical for testing plastics, automotive dashboards, exterior coatings, photovoltaic components, and outdoor textiles that demand fade resistance and gloss retention validation.

2️⃣ Automated Closed-Loop Irradiance & BPT Accuracy

Equipped with a real-time UV radiometer (±5% tolerance) and black panel sensor (BPT control ±0.5°C), the machine prevents deviation in exposure results, ensuring repeatability for R&D and production approval.

3️⃣ Programmable Weather Cycles: Sunlight + Rain + Condensation

Customizable water spray cycles (1–9999h59m) simulate rain shock and surface erosion, while controlled condensation moisture recreates polymer hydrolysis, adhesion failure, and textile mold formation—testing scenarios not achievable by UV-only testers.

4️⃣ Optimized Lamp Life & Cooling System

Mechanical compression refrigeration paired with advanced heat extraction extends xenon lamp utilization beyond 1600 hours, reducing consumable cost without compromising radiation uniformity.

5️⃣ Touchscreen, Standard-Preset, Fully Customizable

Aligned with ASTM G151, ASTM G155, ISO 4892-2, AATCC TM16, and ISO 105-B02 shorten operation setup and maintain globally recognized test repeatability.

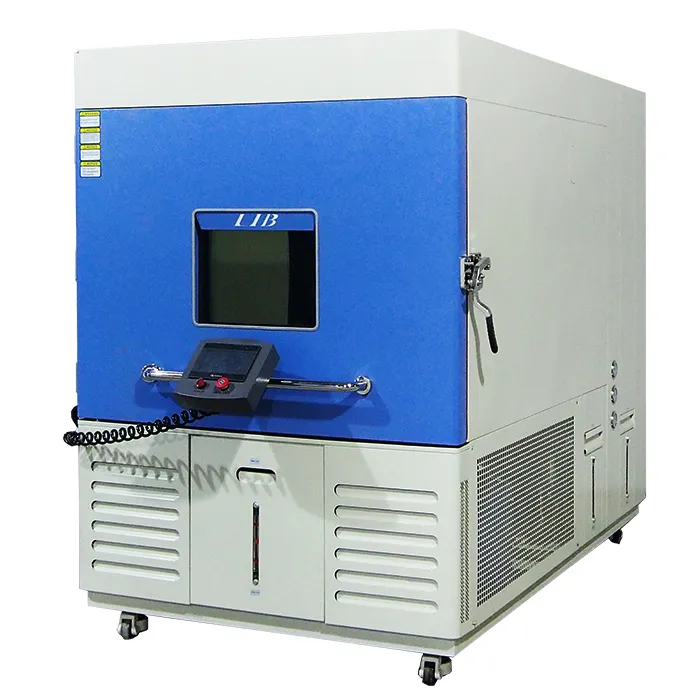

Core Technical Parameters — ASTM G151 G155 Xenon Light Radiation Exposure Test Machine

Model | XL-S-750 |

Internal Dimension (mm) | 950*950*850 mm |

Overall Dimension (mm) | 1400*1400*1950 mm |

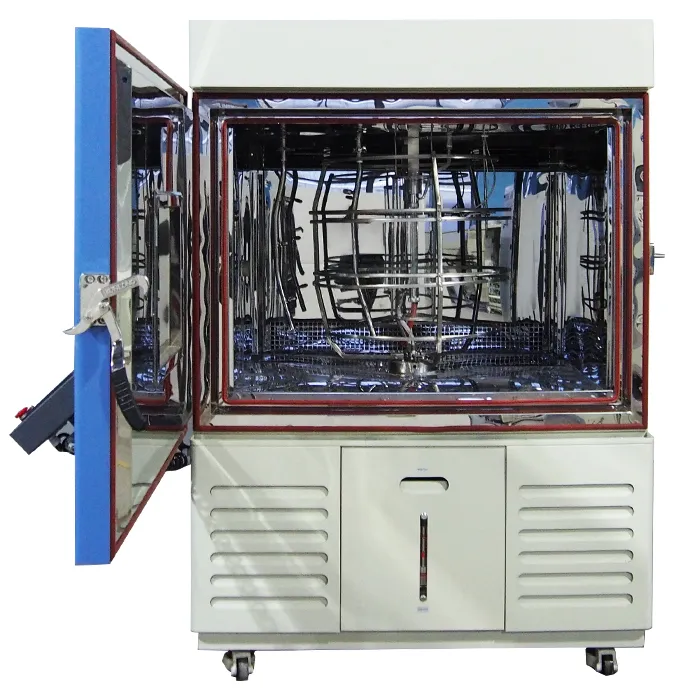

Chamber Type | Rotating Holder Holds 42 Samples with a Size of 95mm*200mm |

Irradiation Source | 1 piece of 4500w water-cooled xenon arc lamp |

Irradiance Range | 35~150 W/㎡ |

Bandwidth Measurement | 300nm~400nm (340nm or 420nm) |

Chamber Temperature Range | Ambient ~ 100 ℃ ±2℃ |

Black Panel Temperature | BPT 35 ~ 85 ℃ ±2℃ |

Humidity Range | 50% ~ 98% RH |

Humidity Deviation | ± 5% RH |

Water Spray Cycle | 1~9999H59M (Adjustable) |

Controller | Programmable color LCD touch screen controller |

Radiometer | UV Radiometer, Tolerance: ±5% |

Cooling System | Mechanical compression refrigeration system |

➡ Parameters are optimized for flexible exposure practice (G151) and xenon arc accelerated degradation standards (G155).

Key Engineering Details – ASTM G151 G155 Xenon Light Radiation Exposure Test Machine

Xenon Lamp System | Power & Type: 4500W water-cooled xenon arc lamp, full-spectrum output. Lifespan: ≥1600 hours of stable operation. Feature: Delivers consistent irradiation for accurate degradation kinetics Cooling: water cooling prevents heat hotspots, ensuring stable light source output. Optical Filter Options: Daylight / Window glass / Extended UV

|

|

Specimen Holder | |  |

Water Circulation & Spray System | System: Automated water supply with purification preventing blockage, adjustable spray cycles (1–9999H59M),and to supply water for cooling the xenon lamps Function: Simulates condensation, rainfall, hydrolysis, and wet-dry fatigue critical for predicting outdoor service life

|  |

Programmable Controller | Interface: Programmable industrial touchscreen. Capabilities: Real-time monitoring of irradiance, black panel temperature, humidity, and spray cycles; pre-configured ASTM G151/G155 test programs,allowing easy data logging for lifetime performance analysis.The equipment can be remotely connected and the data can be exported.

|

|

FAQ — ASTM G151 G155 Xenon Light Radiation Exposure Test Machine

Q1: Is the ASTM G155 test only for plastics?

No—it's widely used for automotive interiors, coatings, packaging, rubber, and textiles that require fade, embrittlement, and gloss retention evaluation.

Q2: Can the xenon exposure machine replicate tropical or high-altitude UV intensity?

Yes—irradiance programming supports enhanced UV exposure beyond standard sunlight profiles for accelerated failure mapping.

Q3: Can I perform salt spray + xenon weathering combined testing?

Yes. LIB industry provides salt spray and cyclic corrosion testers that complement xenon exposure for full-scope outdoor durability.

Predict Outdoor Service Life with ASTM G151 G155 Xenon Light Radiation Exposure Machine

Contact LIB industry today inquiry@libtestchamber.com to configure your ASTM G151 G155 Xenon Light Radiation Exposure Test Machine — engineered for accelerated durability verification, global standards alignment, and lifetime cost risk reduction.

Fast Delivery | Multi-Industry Compatibility | Custom Size & Performance Options

3-Year Warranty & Lifetime Support

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia