Salt Spray Test Equipment Features and Benefits

Wide Environmental Control Capability

· Temperature range: +10℃ to +90℃

· Humidity range: 30% to 98% RH

Accurately reproduces high-salinity corrosion environments and wet corrosion conditions required by NSS, AASS, and CASS tests.

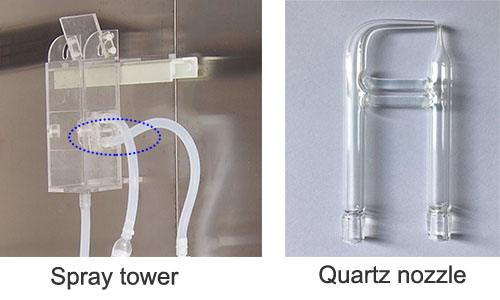

Stable and Uniform Salt Fog Generation

· Precision spray tower with adjustable height

· Anti-crystallization, non-deforming spray nozzle

Ensures uniform fog distribution and stable salt deposition rate of 1–2 ml/80 cm²·h, delivering repeatable and comparable test results.

Pneumatic Lid Design

· Smooth pneumatic opening and closing

Improves operator safety and efficiency, especially during long-term or frequent testing cycles.

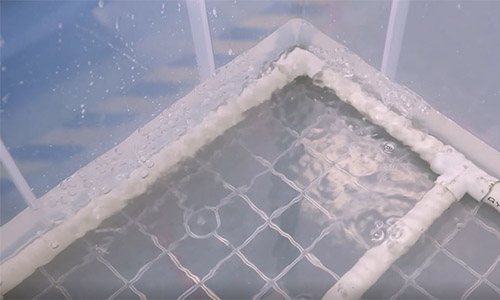

High Durability Corrosion-Resistant Structure

· Upgraded glass fiber reinforced plastic (FRP) workroom

Provides excellent resistance to aging, corrosion, and salt leakage, extending equipment service life under continuous salt spray exposure.

Full Customization Capability

· Workroom dimensions

· Performance configuration

· Sample holders and accessories

Allows adaptation to oversized samples, irregular geometries, or batch testing requirements.

Specifications of Salt Spray Test Equipment

Model | SC-010 | SC-016 | SC-020 |

Internal dimensions (mm) | 1300*1000*600 | 1600*900*720 | 2000*1000*800 |

Overall dimensions (mm) | 2000*1300*1600 | 2300*1300*1700 | 2700*1300*1900 |

Interior Volume (L) | 780 | 1280 | 1800 |

Temperature Range | +10 ℃ ~ +90 ℃ |

Humidity Range | 30% ~ 98% RH |

Salt Fog Deposition | 1~2ml / 80cm2 · h |

Cooling system | Mechanical compression refrigeration system |

Water supply system | Water purification system |

Air Preheating | Saturated air barrel (31Liter) |

Spraying System | Atomizer tower and Spray nozzles |

Salt Fog Collected | Fog collector and fog measure cylinder |

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Safety Device | Humidifier Dry-combustion Protection; Over-temperature Protection; Over-current Protection; Water Shortage Protection; Earth leakage Protection |

Material | Glass fiber reinforced plastics |

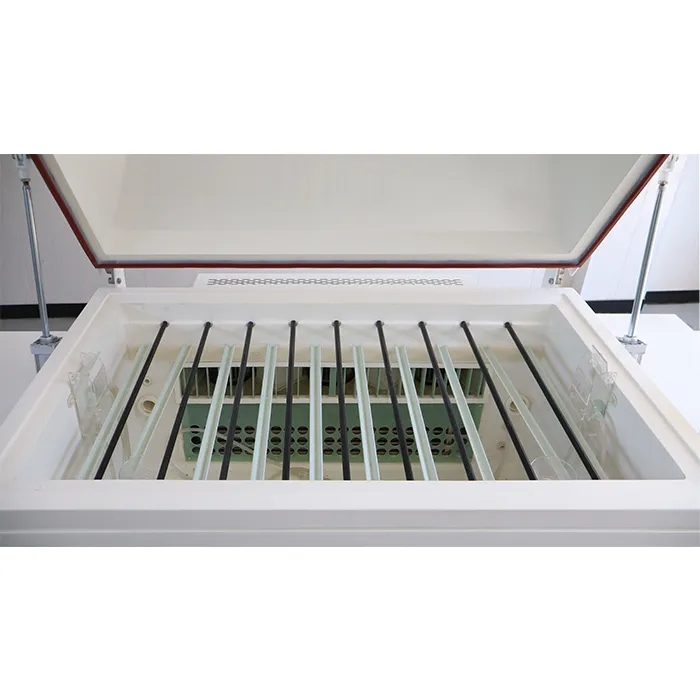

Standard Configuration | 8 round bars |

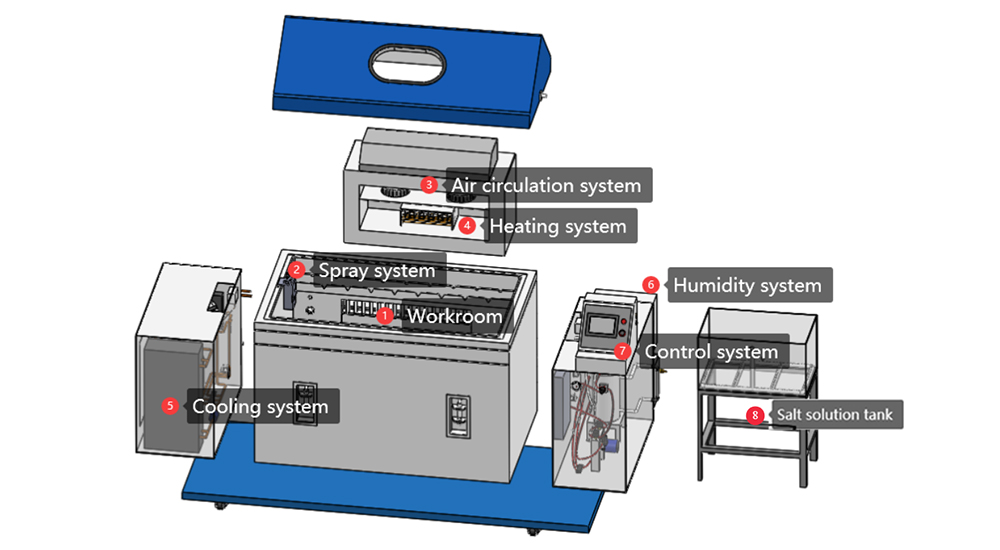

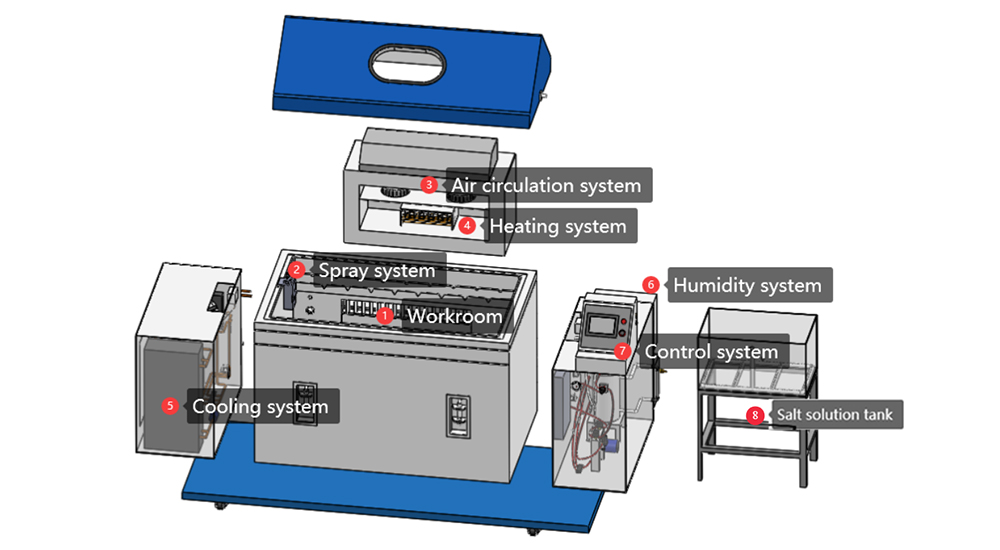

Configuration of Salt Spray Test Equipment

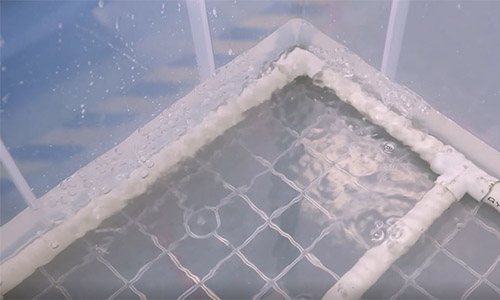

①Workroom | Upgraded FRP material, aging resistant, corrosion resistant, easy to clean, no leakage. Sample holder design of round rod and V-shaped groove, sample test Angle can be adjusted.

|

|

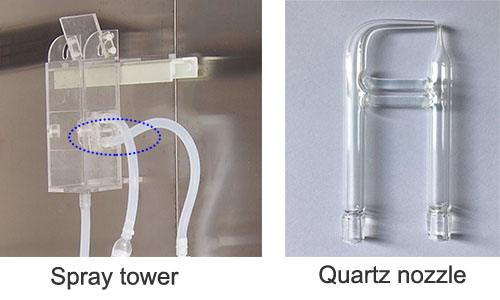

②Spray tower | Spray tower: The nozzle is installed inside and its spire height can be adjusted to guide the fog and spread the fog evenly. Nozzle: no deformation, no crystallization, stable spray volume, and spray fog particles are small.

|

|

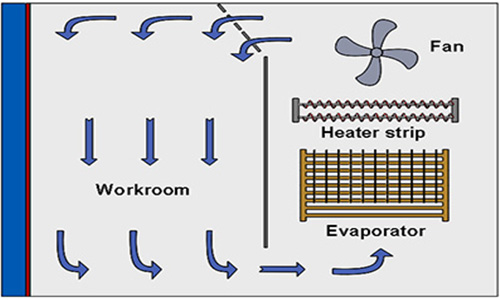

③Refrigerating system | The cooling system automatically opens or closes and adjusts the cooling capacity according to the feedback data from the temperature sensor. |

|

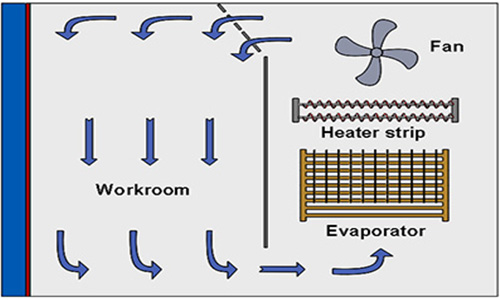

④Air circulation system | Forced air convection makes the temperature, humidity and salt spray in the equipment evenly distributed to ensure the stability and consistency of the test environment. |

|

⑤Heating system | Built-in nickel-chromium alloy heating core, salt resistance, corrosion resistance, fast heating, uniform temperature distribution, installed at the bottom of the equipment. |

|

⑥Humidity system | External isolation, stainless steel surface evaporation humidifier. |

|

⑦Control system | Programmable controller, automatic running test. To achieve the temperature, humidity, spray time, spray cycle and other parameters set and adjust, and store data. |

|

⑧Salt solution tank | Made of PVC plate for storing brine solution, with brine mixing design to stabilize PH. |

|

Why Choose LIB Industry Salt Spray Test Equipment

LIB industry delivers more than standard salt spray testing systems. We provide engineering-level corrosion test solutions tailored to your application and standards.

3-year warranty covering complete system reliability

Lifelong technical support from experienced engineers

1–3 hour rapid remote response to minimize test interruptions

Global spare parts availability for long-term operation security

Contact us today inquiry@libtestchamber.com to receive detailed specifications, pricing, and a professional corrosion testing solution tailored to your needs.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia