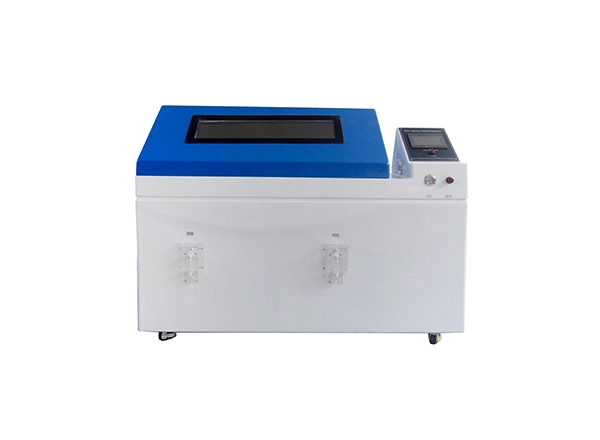

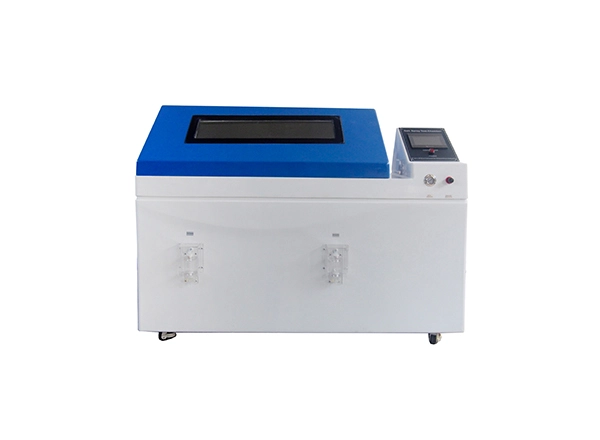

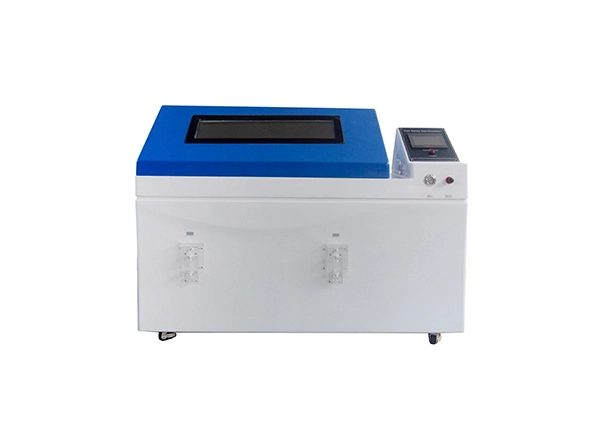

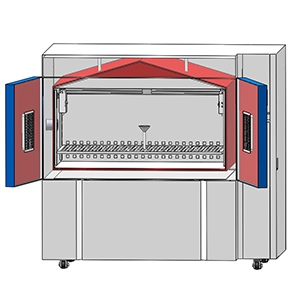

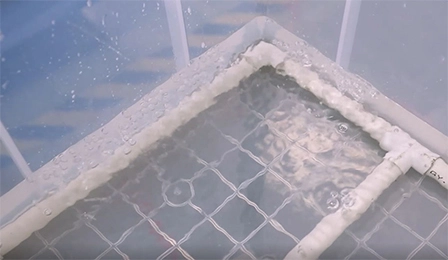

FRP material, strong corrosion resistance, high temperature resistance, one molding, reinforced design, long service life.

Salt spray chamber simulates the salt spray environment and test the salt spray corrosion resistance of various materials and products. Salt spray chamber can conduct NSS, AASS and CASS test complying with ASTM B117, ISO 9227 and other relevant standards. The chamber body is usually made of glass fiber reinforced plastics,which has strong corrosion resistance.

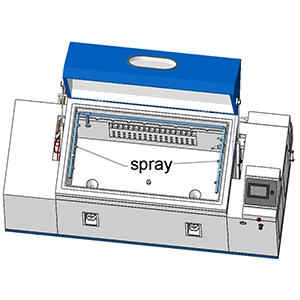

Salt spray chamber can accurately reproduce corrosion in marine or high-salinity environments with controlled salt spray deposition, and its salt spray unit can evenly spray salt spray to ensure that the surface of the sample is uniformly affected by corrosion. There are various types of salt fog cabinets, such as salt fog test equipment, offered at LIB Industry at competitive factory price! If you want to know more, just be free to contact us!

Salt spray test chamber, a type of environmental test chamber for sale at LIB Industry, is widely used, mainly involving materials including metal, coating, plastic and so on. The purpose is to improve the corrosion resistance of the product through salt spray test.

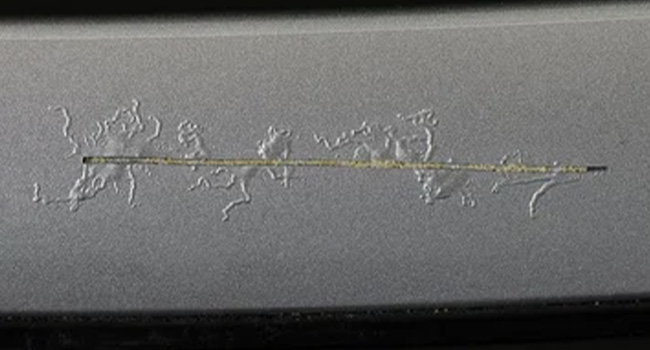

Many parts of the car may come into contact with rain, snow, salt on the road, such as areas where salt is used to remove snow. After painting, it is necessary to check the salt spray corrosion resistance.

Salt spray corrosion tests to simulate such as marine climate on electronic components to evaluate their corrosion resistance and reliability in harsh environments, such as circuit board lines and solder joints are susceptible to corrosion.

Daily hardware products such as door locks, handles, hinges, faucets, screws, etc., are susceptible to corrosion by salt spray. Decorative hardware needs to have good corrosion resistance.

Aluminum alloy doors and windows, curtain walls and other building materials, construction steel such as steel bars, steel beams, steel columns, etc., are prone to corrosion problems in marine climate or high salinity areas.

Ships travel in the marine environment, parts and coatings in long-term contact with seawater and salt spray need to have good salt spray corrosion resistance.

FRP material, strong corrosion resistance, high temperature resistance, one molding, reinforced design, long service life.

By controlling temperature and salt spray concentration, highly realistic simulation of salt spray corrosion environment such as the climate around the ocean.

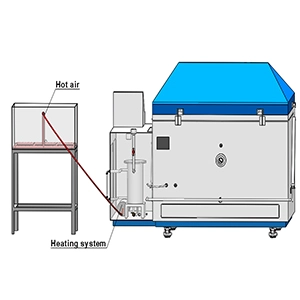

A brine mixing system is installed in the brine tank to ensure the uniformity of the salt solution, and the brine can also be heated to stabilize the PH value.

The air compressor, salt water tank and spray tower constitute the tower salt spray system, and coordinate the function to produce diffuse salt spray through the siphon principle.

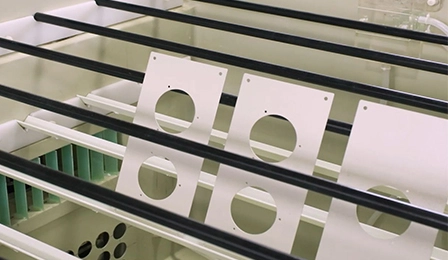

Standard sample holder and customized sample holder for special-shaped products to ensure uniform salt spray contact surface.

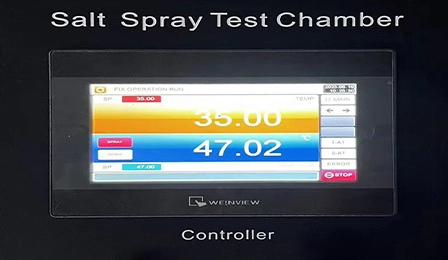

Advanced PID control system, 12 languages are available.LCD displays test conditions (including temperature, cycle number, salt fog disposition, etc.).

1. Test requirements: Determine the type of test and standards you need to perform, such as ASTM B117, ISO 9227 and etc.

2. Capacity and sample holder: LIB Industry salt fog cabinet has a variety of models, according to your test needs and sample size to choose the appropriate capacity of salt spray test chamber.

3. Control system: LIB Industry salt fog cabinet with PID controller, can accurately control the temperature, humidity, salt spray deposition to ensure the accuracy and reliability of test results.

4. Control system: LIB Industry salt fog cabinet with PID controller, can accurately control the temperature, humidity, salt spray deposition to ensure the accuracy and reliability of test results.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español