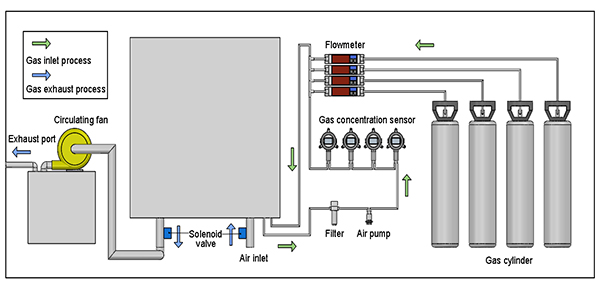

When engineers completed the corrosion resistance test of the cable joint in the SO2 noxious gas test chamber in LIB, the remaining was not directly discharged into the atmosphere, but underwent a purification journey.

The LIB SO₂ noxious gas test chamber uses a dynamic gas circulation system to accurately control SO₂ concentration (0-500ppm), temperature and humidity (-40℃~150℃, 10%~98%RH) and pressure parameters to simulate the material corrosion process in extreme industrial environments.

Model | SO-100 | SO-225 | SO-500 | SO-800 | SO-1000 |

Internal Dimensions (mm) | 400*500*500 | 500*600*750 | 700*800*900 | 800*1000*1000 | 1000*1000*1000 |

Overall Dimensions (mm) | 860*1050*1620 | 960*1150*1860 | 1180*1350*2010 | 1280*1550*2110 | 1500*1550*2110 |

Interior Volume (L) | 100 | 225 | 500 | 800 | 1000 |

Temperature Range | 15 ℃ ~ 80 ℃ | ||||

Temperature Fluctuation | ± 0.5 ℃ | ||||

Temperature Deviation | ± 2.0 ℃ | ||||

Humidity Range | 30% ~ 98% RH | ||||

Humidity Deviation | ±1% RH | ||||

SO2 Concentration | 25±5 ppm | ||||

Air Change Rate | 3~5 /h | ||||

| |||||

1. Gas leakage monitoring: high-precision sensor monitors the gas concentration inside chamber in real time, and automatically triggers the emergency exhaust system when exceeded;

2. Double sealing structure: fluorine rubber seal ring and lock design to ensure zero gas leakage;

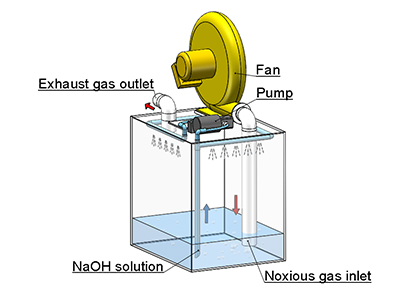

3. The SO2 noxious gas test chamber is equipped with an independent SO2 purification device to neutralize and react with residual SO₂ (SO₂ + 2NaOH → Na₂SO₃ + H₂O).

LIB not only provides a single SO₂ gas corrosion test chamber, but also introduced a mixed toxic gas test chamber, which can simulate the mixed gas environment such as SO₂, NO₂, H₂S and CL2 at the same time to meet the needs of material reliability verification under complex conditions.

For example, automotive electronic components need to withstand the coordinated erosion of sulfur-containing and industrial exhaust gases in high temperature and humidity environments, and the mixed gas test chamber can accelerate the exposure of potential defects in the product by precise proportions.

The full range of LIB environmental chambers enjoy a 3-year warranty, perfect after-sales service and 5 service centers around the world to ensure that your testing journey is trouble-free. Whether standard or custom SO2 toxic gas test chambers, LIB can be delivered quickly according to your needs. Leave your request and the LIB team will contact you as soon as possible.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia