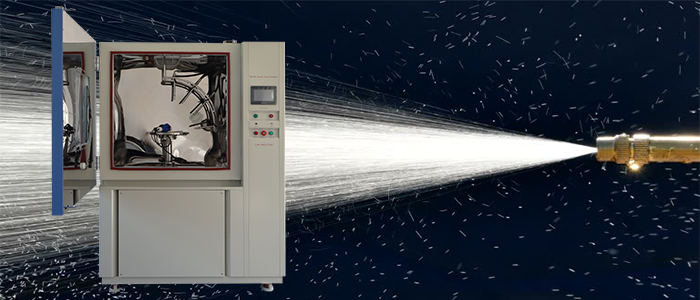

In an era where durability defines brand reputation, manufacturers face increasing pressure to ensure products can endure extreme environmental conditions. From heavy rainfall to high-pressure cleaning, water exposure remains a top concern across automotive, electronics, industrial, and defense sectors. The LIB IPX9K test machine provides a complete solution, combining precise engineering, advanced control, and robust safety features to guarantee reliable waterproof testing.

The LIB IPX9K test machine is engineered for high-pressure, high-temperature water spray testing, meeting ISO 20653, IEC 60529, and DIN 40050-9 standards. It is designed to simulate the harshest real-world conditions, offering repeatable and accurate results for diverse applications.

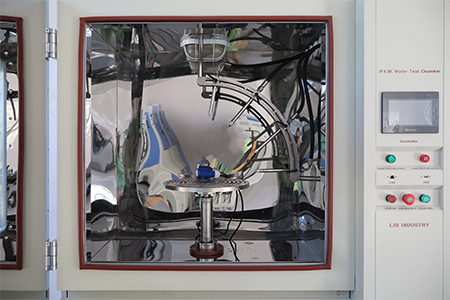

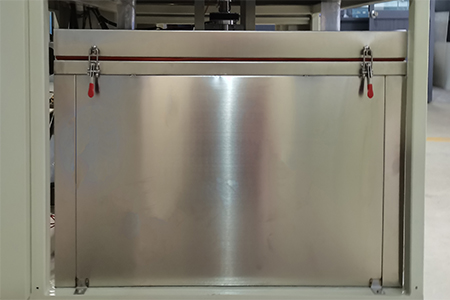

· Chamber Design – Workroom constructed from corrosion-resistant SUS304 stainless steel, the chamber accommodates small electronics to large automotive parts.

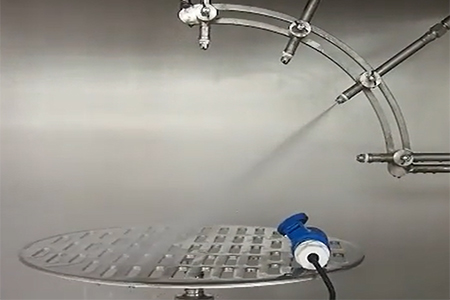

· Spray System – Four adjustable nozzles deliver water jets at 0°, 30°, 60°, and 90°, ensuring uniform coverage.

|  |

· Water Supply and Filtration – Equipped with a high-pressure pump and filtration system for consistent spray and reduced maintenance.

· Temperature Control – Integrated heaters maintain water temperature up to 80°C, simulating hot wash or rain conditions.

|

Model | R9K-1200,more models can be customized. |

Interior Volume (L) | 1200 |

Water Spray Angle | 0°, 30°, 60°, 90° |

Water Spray Temperature | Ambient ~ +88℃ (Adjustable) |

Spray Nozzle | Four, 30 Seconds each position |

Distance from Water Spraying to Specimens | 10~15cm |

Water Pressure | 8000-10000 Kpa (Adjustable) |

Water Flow Rate | 14L-16L/min |

Testing Platform Speed | 5±1 r.p.m |

Testing Platform Height | 200-400 nm (Adjustable) |

Testing Platform Diameters | 600mm |

Water supply system | Storage water tank; Booster pump; Automatic water supply; Water purification system; |

Safety Device | Over-temperature Protection; Over-current Protection; Water Shortage Protection; Earth Leakage Protection; Phase Sequence Protection |

· Programmable Touchscreen Controller – Allows setting spray duration, pressure, flow rate, and temperature for precise testing cycles.

· Automated Operation – Reduces human error and ensures consistency across repeated tests.

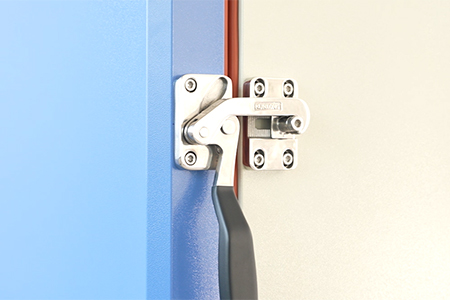

· Safety Locks and Anti-Slip Flooring – Protect operators during high-pressure testing.

· Overload Protection – Prevents mechanical or electrical failure during operation.

|  |

Automotive components are increasingly complex, integrating sensors, cameras, lighting modules, and electronic control units (ECUs) that must operate flawlessly under all weather conditions.

Manufacturers face challenges such as:

- High-pressure car washes causing water ingress

- Road spray during heavy rain or off-road driving

- Exposure to hot water during industrial cleaning processes

Consumer and industrial electronics are no longer confined indoors. Outdoor displays, smartphones, IoT devices, and 5G base stations must endure harsh environmental conditions.

Common pain points include:

- Waterproofing failures during exposure to rain or splashing

- Limited lab capabilities to replicate extreme water conditions

- Long testing cycles delaying product launches

Industrial machinery, control cabinets, and heavy-duty enclosures often operate in wet or corrosive environments.

Water ingress can lead to:

- Equipment downtime

- Safety hazards for operators

- Expensive repairs or replacements

Mission-critical defense and aerospace systems must remain fully operational under extreme weather, including high-pressure water exposure. Traditional testing methods often fall short of real-world conditions, risking mission failure.

The LIB IPX9K test machine provides:

- Precise multi-angle water jet testing aligned with military standards

- Controlled high-temperature water exposure for comprehensive evaluation

- Reliable and repeatable results for component certification

By leveraging LIB’s advanced IPX9K test solutions, defense and aerospace engineers can ensure equipment survives the harshest operational environments.

· Global Standards Compliance – Aligns with ISO, IEC, and DIN certifications.

· Customizable Solutions – Chamber dimensions and test parameters tailored to industry needs.

· Robust Durability – Stainless steel construction minimizes maintenance and maximizes lifespan.

· Smart, Safe Operation – Intelligent control, automated testing, and safety mechanisms protect operators.

· Expert Support – Installation, training, and after-sales service provide end-to-end assistance.

Ensure your products are built to withstand the toughest water exposure. With the LIB IPX9K test machine, manufacturers across automotive, electronics, industrial, and defense sectors can achieve certified waterproof performance and enhance product reliability.

Contact LIB today inquiry@libtestchamber.com to request a consultation or quote, and discover how our IPX9K test machine can safeguard your products and strengthen your brand reputation.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia