In the world of modern engineering, materials are expected to perform under extreme and varied conditions. Whether it's high temperatures, corrosive atmospheres, or UV radiation, understanding how materials behave in these environments is critical for safety, quality assurance, and product longevity. This is where environmental test chambers come into play.

LIB Industry, with over a decade of experience in environmental simulation technology, offers a comprehensive range of environmental chambers tailored specifically for materials testing. These systems are designed to simulate a wide array of environmental conditions, allowing manufacturers and researchers to evaluate the physical, chemical, and mechanical behavior of materials before they are used in real-world applications.

Materials often expand and contract with temperature changes, which can lead to fatigue, cracking, or failure over time. LIB’s thermal cycling chambers are engineered to repeatedly expose materials to a wide range of temperatures—either gradually or rapidly—helping evaluate dimensional stability, elasticity, tensile strength, and other key performance metrics.

Temperature range: -20/-40/-70°C to +150°C

Rapid temperature ramp rates: 5℃/min or higher(customized)

Precise temperature control (±0.5°C)

Optional humidity control (typically 20%~98%RH)

Application Example: Polymer composites used in aerospace components undergo repeated thermal cycling to ensure they maintain structural integrity from high-altitude cold to engine heat proximity.

Similar to thermal cycling, temperature cycling tests simulate exposure to alternating high and low temperatures over extended cycles to determine thermal durability. LIB Temperature Cycling Chambers offer flexible programming capabilities to meet industry-specific test profiles.

Key Industries:

Automotive: Testing under-hood plastics

Electronics: PCB solder joint integrity

Construction: Outdoor sealants and insulation performance

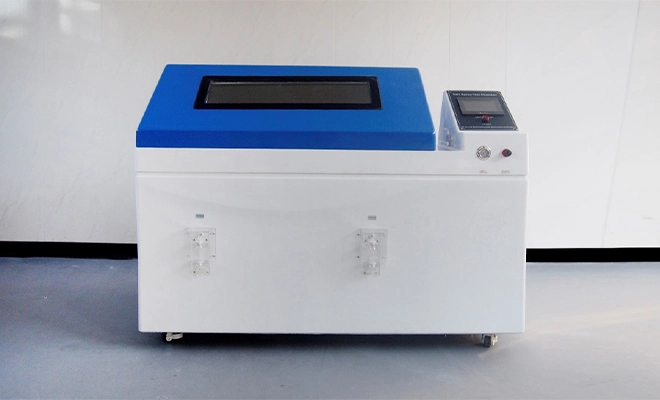

Corrosion can drastically reduce the lifespan of metals, coatings, and polymers. LIB corrosion test chambers replicate real-world corrosive atmospheres such as salt fog, sulfur dioxide (SO₂), and mixed gas environments to accelerate the corrosion process and evaluate the protection performance of materials.

LIB Corrosion Chambers Include:

Salt Spray Chambers / Salt Mist Test Chambers

Cyclic Corrosion Test Machines

All systems comply with international standards such as ASTM B117, ISO 9227, and DIN 50021.

Example Application: Automotive manufacturers use LIB’s salt fog chambers to test the rust resistance of body panels, fasteners, and coatings before market release.

To understand how materials age, LIB accelerated aging chambers expose samples to high temperature, humidity, UV light, and chemical exposure in a condensed timeframe. This allows researchers to simulate months or even years of environmental exposure in just weeks.

Popular Solutions from LIB:

UV Light Fastness Test Chambers (ASTM G154, ISO 4892-3)

Xenon Arc Weathering Chambers (ASTM G155)

Custom-built accelerated aging systems

These systems are widely used for testing plastics, textiles, coatings, and packaging materials.

Real-World Use Case: Paint manufacturers utilize LIB’s xenon test chambers to assess color stability and surface degradation under full-spectrum sunlight simulation.

For over 10 years, LIB Industry has been supporting R&D labs, quality departments, and manufacturing firms worldwide with customized environmental chamber solutions. From standard models to fully tailored systems with multi-axis fixtures, advanced data logging, and remote monitoring, LIB offers unmatched flexibility and reliability.

Comprehensive testing range: thermal, humidity, UV, corrosive gas

Compliance with international testing standards

Proven performance in aerospace, automotive, electronics, and polymer industries

Customization available to suit unique sample sizes and test protocols

Materials are the foundation of every engineered product—and understanding how they behave under various environmental conditions is essential to ensuring durability and functionality. LIB Environmental Chambers offer a robust, accurate, and industry-standard solution for simulating these environments and enhancing the quality of material-based products.

Whether you're testing polymers, metals, coatings, textiles, or composites, LIB provides a trusted platform to carry out your evaluations with precision and confidence.

Learn more about our materials testing chambers or contact LIB to customize a solution for your laboratory or production line.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia