In product development, water ingress protection (IP) testing failures often result in delayed certification, repeated redesigns, and increased compliance costs. For manufacturers of electronics, automotive components, outdoor equipment, and industrial enclosures, ensuring waterproof performance before market release is not optional—it is a decisive factor for reliability, safety, and brand credibility.

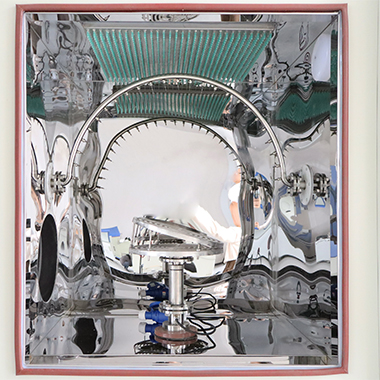

A Water Spray Test Chamber , also known as a Rain Test Chamber, enables manufacturers to simulate controlled water exposure conditions in accordance with international IP standards. Rather than discovering weaknesses during field use or third-party audits, engineers can identify sealing defects, enclosure vulnerabilities, and coating limitations early in the laboratory.

|

|

LIB industry designs water spray test chambers not merely as testing equipment, but as IP compliance tools—supporting accurate, repeatable, and standard-aligned testing that helps products pass certification on the first attempt.

A Water Spray Test Chamber is engineered to reproduce rainfall, splashing water, and high-pressure water jets under precisely controlled conditions. Adjustable spray nozzles, oscillating tubes, and programmable test cycles allow manufacturers to evaluate how products respond to water exposure from different directions, intensities, and durations.

The system verifies waterproof performance against IPX1, IPX2, IPX3, IPX4, IPX5, and IPX6 protection levels, assessing:

· Sealing integrity of enclosures and joints

· Resistance to water penetration

· Durability of surface coatings and protective layers

· Reliability of electrical components under wet conditions

By simulating real-world environmental stress in a controlled laboratory environment, engineers can make data-driven design improvements before products enter mass production.

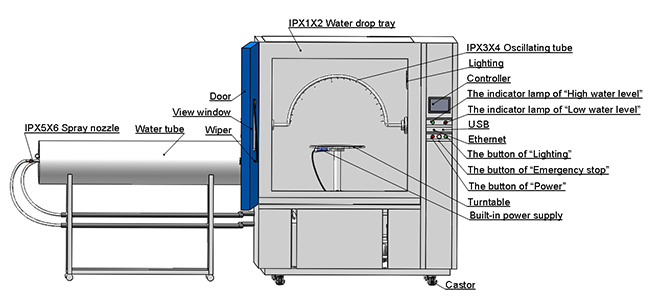

Unlike single-function rain testing devices, LIB industry water spray test chambers integrate multiple IPX test methods into one configurable platform. A single system can complete:

· IPX1–IPX2: Vertical dripping water tests

· IPX3–IPX4: Oscillating tube and spray tests

· IPX5: Water jet testing using 6.3 mm nozzles

· IPX6: Powerful water jet testing using 12.5 mm nozzles

Model | RD-800C | RD-1200C |

Useful Volume (L) | 810 | 2400 |

Drip Tray Size | 600*600 | 1000*1000 |

Oscillating Tube Radius | 400mm | 600mm |

Water Jetting Tube | 2400mm | 2300mm |

Spraying Hole Diameter | φ0.4mm | |

Hole Spacing | 50 mm | |

oscillating angle of Oscillating Tube | 0 ~ ±180° (Adjustable) | |

Jet nozzles | IPX5: Dia6.3mm, IPX6: Dia12.5mm | |

Jet distance | 2.5~3meter | |

Turntable Rotation Speed | 1r/min (Adjustable speed) | |

Controller | Programmable color LCD touch screen controller, Ethernet connection, USB port | |

Water supply system | Water tank, booster pump, Automatic water supply, Water purification system | |

Interior Material | SUS304 stainless steel | |

Observation Window | Double layer insulating glass with wiper | |

| ||

This integrated design allows manufacturers to:

· Avoid investing in multiple standalone systems

· Perform progressive IP testing throughout product development

· Prepare for future product upgrades without equipment replacement

To support complete ingress protection evaluation, LIB industry also provides IPX7 and IPX8 immersion test equipment as well as IPX9K high-pressure water jet systems, enabling customers to build a fully compliant IP testing laboratory tailored to their certification roadmap.

|  |

High test accuracy depends on mechanical precision and intelligent control. LIB industry water spray test chambers are engineered with this principle at the core.

· Uniformly machined spray holes (φ0.4 mm) ensure consistent droplet formation

· Controlled hole spacing (50 mm) prevents uneven exposure

· Precision jet nozzles strictly match IPX5 and IPX6 requirements

The programmable color LCD touch screen controller allows users to define:

· Spray pressure and water flow rate

· Oscillation angle (0 ~ ±180° adjustable)

· Turntable rotation speed

· Test duration and sequence

All test parameters are monitored and recorded, supporting traceable, repeatable, and auditable test results for quality assurance and certification review.

The SUS304 stainless steel interior resists corrosion and prevents contamination, ensuring long-term testing stability. The double-layer insulated observation window with wiper allows clear monitoring without interrupting the test process.

Water spray test chambers are widely used across industries that require verified waterproof performance:

· Electronics: Sensors, control panels, handheld devices, and enclosures

· Automotive: Headlamps, rear-view cameras, connectors, and sealing systems

· Construction Materials: Exterior coatings, sealants, facade materials

· Aerospace and Defense: Environmental endurance validation of mission-critical components

· Consumer Products: Outdoor lighting, power tools, and weather-resistant enclosures

Each application demands reliable, standard-aligned testing—making equipment stability and accuracy essential.

Whether you are validating a new product design or upgrading your laboratory’s testing capability, LIB industry provides scalable water spray testing solutions aligned with your standards and application requirements.

Receive a quotation and preliminary test plan within 1–3 hours.

3-Year Warranty | Custom Configurations | Lifetime Technical Support

Contact LIB industry today inquiry@libtestchamber.com to design a Water Spray Test Chamber solution that helps your products pass IP testing with confidence.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia