Why Industries Trust the Xenon Light Fastness Aging Test Device from LIB Industry

1. Full-Spectrum High-Intensity Solar Simulation

With UV–VIS–IR full-spectrum simulation, a 4500W high-stability water-cooled xenon lamp, and a broad adjustable irradiance range of 35–150 W/m², this xenon light fastness aging test device faithfully replicates natural sunlight from normal outdoor exposure to high UV environments.

2.Comprehensive Climate Cycle Simulation

Combining a programmable water spray cycle (1–9999h59m) with day–night condensation cycles, this xenon light fastness aging test device reproduces rainfall, surface washout, dew condensation, and humidity alternation in laboratory conditions.

3. Stable Design for Consistent and Reliable Operation

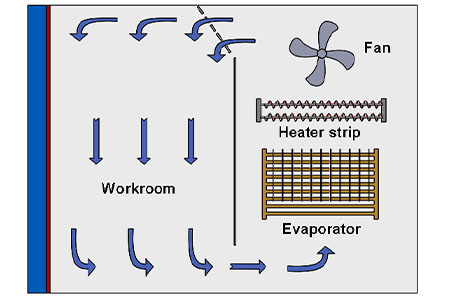

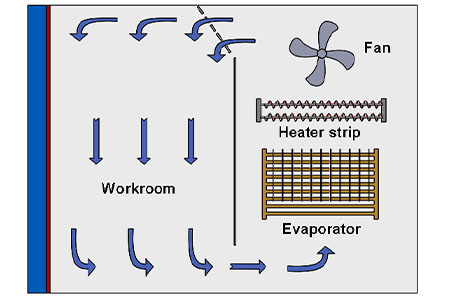

Equipped with water-cooled lamp control, a mechanical refrigeration chamber, and lamp overload protection, the device maintains spectral stability under high energy, prevents chamber temperature fluctuations, and avoids thermal shock to the lamp.

4. Multi-Industry Versatility

Ideal for automotive components, plastics, photovoltaics, textiles, building materials, coatings, packaging, and rubber. Supports testing of color fastness, gloss retention, structural durability, and surface degradation.

5. Uniform Xenon Test Device Design Ensures High Repeatability

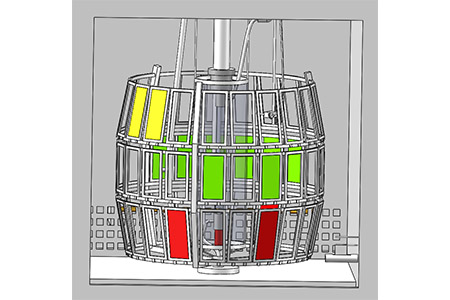

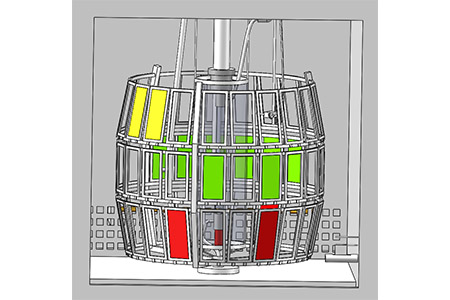

With an independent air circulation system and a 360° rotating sample holder, the device ensures uniform airflow without disturbing light distribution, providing consistent irradiance, humidity, and temperature for all samples.

Core Technical Parameters — Xenon Light Fastness Aging Test Device

Model | XL-S-750 |

Internal Dimension (mm) | 950*950*850 mm |

Overall Dimension (mm) | 1400*1400*1950 mm |

Specimen Holder Size(mm) | 95*200 |

Specimen Capacity | 42pcs |

Chamber Type | Rotating Holder |

Irradiation Source | 1 piece of 4500w water-cooled xenon arc lamp |

Irradiance Range | 35~150 W/㎡ |

Bandwidth Measurement | 300nm~400nm (340nm or 420nm) |

Chamber Temperature Range | Ambient ~ 100 ℃ ±2℃ |

Black Panel Temperature | BPT 35 ~ 85 ℃ ±2℃ |

Humidity Range | 50% ~ 98% RH |

Humidity Deviation | ± 5% RH |

Water Spray Cycle | 1~9999H59M (Adjustable) |

Controller | Programmable color LCD touch screen controller |

Water supply system | Automatic water supply, Water purification system |

Radiometer | UV Radiometer, Tolerance: ±5% |

Cooling System | Mechanical compression refrigeration system |

Engineering Highlights – Xenon Light Fastness Aging Test Device

Xenon Lamp System | Power & Type: 4500W water-cooled xenon arc lamp(Water-cooled circulation system) Full-Spectrum Output: UV + Visible + IR Lamp Life: ≥1600 hours of stable operation Spectral Monitoring: 300–400 nm, optional 340 nm / 420 nm Filters Available: Daylight, Window Glass, Extended UV

|

|

Sample Holder | Type: Three-layer rotating holder,360° uniform exposure Capacity: 42 samples (standard 95 × 200 mm each) Customization: Supports irregular or large-size samples Uniformity: Ensures consistent light, temperature, and humidity for all samples

|  |

Temperature & Humidity Control | Chamber Temperature Range: Ambient – 100°C ±2°C Humidity Range: 50–98% RH ±5% Cooling System: Mechanical compression refrigeration Air Circulation: Independent airflow system, constant volume, no spectral disturbance Environmental Cycles: Programmable light, heat, humidity, condensation, and day–night cycles

|  |

Water Spray System | Cycle Range: 1–9999H59M, fully programmable Water Supply: Automatic, purified, anti-blocking Function: Simulates rainfall, surface erosion, wet–dry fatigue Independent Circuit: Separate water channels for lamp cooling and spray system

|  |

Controller | Interface: Industrial-grade color touchscreen Functions: Real-time monitoring of irradiance, BPT, chamber temperature, humidity, and spray cycles Preloaded ASTM G151/G155, ISO 4892-2, AATCC TM16, ISO 105 programs Data recording and export via USB/Ethernet Remote monitoring and alarm notifications

|  |

Essential Questions About the Xenon Light Fastness Aging Test Device

Q1: How often should the filters and lamps be maintained?

Filters should be inspected and cleaned every 3–6 months depending on usage. Xenon lamps typically require replacement after ~1600 hours of operation to ensure consistent spectral output.

Q2: Does the control interface support multiple languages?

Yes. The industrial touchscreen controller supports multiple languages, allowing global teams to operate and monitor tests with ease.

Q3: Can LIB industry customize the wavelength configuration or sample capacity?

Absolutely. LIB industry provides custom racks, irradiance windows, enhanced UV filters, and chamber volumes tailored to specific test requirements.

Accelerate Material Reliability with the Xenon Light Fastness Aging Test Device

Partner with LIB industry inquiry@libtestchamber.com to configure your xenon light fastness aging test device—designed for global test compliance, enhanced operational efficiency, and long-term material reliability assurance.

Fast Production | Multi-Standard Compatibility | Custom Engineering | 3-Year Warranty and Lifetime Technical Support

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia