In the field of controlled environmental testing, environmental chambers are essential for ensuring product reliability, safety, and performance. From temperature and humidity chamber testing to thermal shock, salt spray, and climatic simulation, these systems are widely used across electronics, automotive, aerospace, energy, and pharmaceutical industries.

Among the most common configurations, benchtop environmental chambers and walk-in environmental chambers serve different testing purposes. This guide provides a structured comparison based on size, capacity, cost, performance, and application scenarios, helping engineers and procurement teams select the right environmental chamber solution for their testing requirements.

| Testing Requirement | Recommended Chamber |

| Small samples, high precision | Benchtop Environmental Chamber |

| Limited lab space | Benchtop Environmental Chamber |

| Large products or batch testing | Walk-In Environmental Chamber |

| Long-duration environmental testing | Walk-In Environmental Chamber |

| Automotive or aerospace system testing | Walk-In Environmental Chamber |

This quick guide helps you identify the optimal environmental chamber for your lab or industrial testing scenario.

Benchtop environmental chambers are designed for laboratories and R&D centers where space efficiency and high precision are priorities. Their compact footprint allows them to be placed on lab benches, enabling flexible layout and relocation.

Despite their size, these chambers support a wide range of environmental tests, including:

· Temperature cycling and thermal shock

· Humidity control

· Ozone exposure and material aging

Benchtop chambers are commonly applied to:

· Battery cells and small battery modules·

· Electronic components such as PCBs, connectors, and sensors·

· Material samples and coatings·

· Early-stage product validation and feasibility studies·

| Aspect | Benchtop Chamber |

| Size | Compact, fits on laboratory benches |

| Mobility | Portable and easy to reposition |

| Test Volume | Small, precise control over samples |

| Control Accuracy | High precision in temperature, humidity, and sometimes pressure |

| Ideal Users | R&D labs, universities, research institutes |

These chambers excel where tight environmental control over small volumes is critical, allowing faster stabilization and efficient test execution.

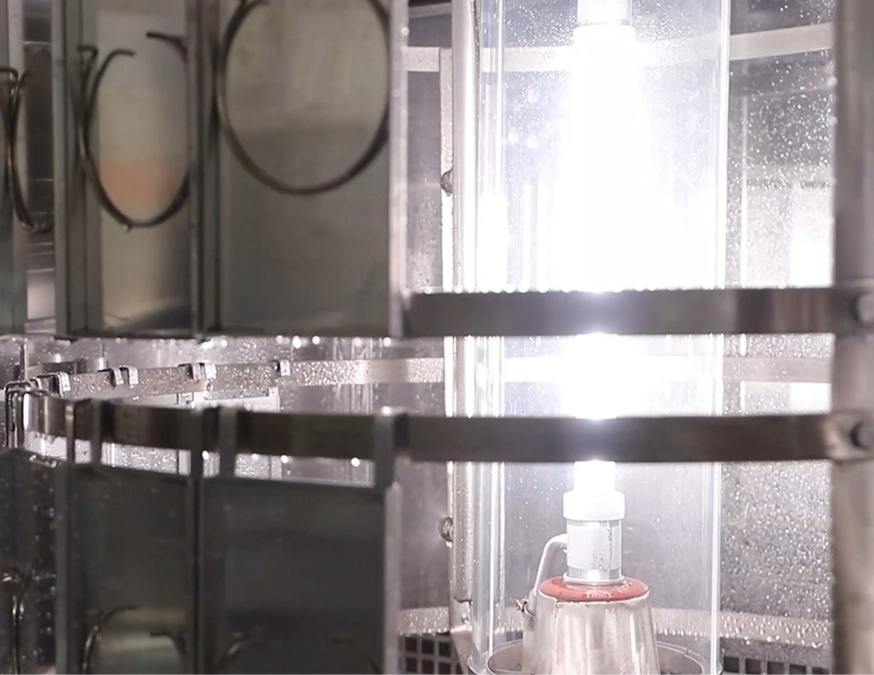

Walk-in environmental chambers are engineered for large-volume and system-level testing. Operators can access the interior to test entire products or assemblies. Walk-in chambers are ideal for:

· Extended temperature and humidity chamber testing·

· Long-term thermal cycling·

· Salt fog and corrosion testing·

· Powered-on reliability assessments·

Walk-in chambers are widely used in:

· Automotive industry: EV battery packs, infotainment systems, wiring harnesses·

· Aerospace and defense: avionics, sensors, structural assemblies·

· Energy and power electronics: inverters, cabinets, control systems·

· Large mechanical or electronic assemblies for industrial QA·

| Aspect | Walk-In Chamber |

| Size | Large, walk-in access for operators |

| Test Capacity | High-volume testing of components or products |

| Load Capability | Heavy or oversized items supported |

| Test Duration | Long-term stability and endurance |

| Ideal Users | Industrial testing centers, production QA labs |

Walk-in chambers maintain uniform environmental conditions across large internal spaces, making them indispensable for system-level qualification testing.

· Lower initial investment·

· Lower installation and operational cost·

· Ideal for small labs requiring precise temperature and humidity testing·

· Higher upfront investment due to size and customization·

· Scalable long-term value for frequent or large-batch testing·

· Reduced per-sample cost for high-throughput operations·

| Cost Factor | Benchtop | Walk-In |

| Initial Investment | Lower | Higher |

| Operating Cost | Moderate | Usage-dependent |

| Maintenance | Simple | Comprehensive |

| Scalability | Limited | High |

Proper evaluation of budget relative to testing requirements ensures an optimal return on investment.

Benchtop chambers offer:

Fast temperature ramp rates

Tight control over humidity

Stable conditions for small-volume tests

Ideal for component-level validation and accelerated aging studies

Walk-in chambers provide:

Consistent temperature and humidity across large volumes

Long-duration environmental simulations

Support for powered-on and full-system tests

Essential for industrial and automotive QA programs

Small component or sample testing

Limited laboratory space

High-precision environmental control required

Short-duration or R&D-focused tests

Large products, batch testing, or system-level testing

Long-duration or powered-on environmental simulations

Automotive, aerospace, or industrial-standard testing

Future scalability and high throughput are priorities

Selecting the right environmental chamber is not just a matter of size; it requires aligning test objectives, product dimensions, duration, and operational needs. Both benchtop and walk-in chambers are critical tools for engineers and lab managers, enabling accurate environmental simulations and reliable test results.

LIB industry offers both custom benchtop and walk-in environmental chambers, tailored to your testing requirements, including:

Flexible temperature and humidity ranges

Application-specific design and configuration

Support for thermal shock, salt fog, and climatic simulationsContact LIB industry

inquiry@libtestchamber.com to discuss your environmental testing requirements and receive a custom solution tailored to your lab or production needs.

3-Year Warranty | Engineered-to-Order | Lifetime Technical Support

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia