Ultraviolet radiation is a major cause of material degradation in outdoor and semi-outdoor environments. Plastics, coatings, and polymer components can fade, crack, or lose mechanical integrity over time, making reliable durability assessment essential for product quality and market success.

Manufacturers and laboratories worldwide rely on LIB industry for ASTM G154 UV test chamber reliable testing solutions. For example, a customer in Serbia testing rubber components reported that our support and chamber performance allowed them to complete accelerated UV aging tests with confidence, ensuring consistent and repeatable results. Feedback like this underscores how our solutions help clients overcome the challenges of long-term material durability testing.

Traditional outdoor exposure testing is slow and unpredictable. To accelerate evaluation while maintaining reliability, standardized accelerated methods like ASTM G154 fluorescent UV weathering testing have become essential for laboratories and manufacturers seeking accurate, repeatable UV durability data.

ASTM G154 is designed to assess the resistance of non-metallic materials to UV radiation, elevated temperature, and moisture by using fluorescent ultraviolet lamps. Instead of attempting to replicate the full solar spectrum, the standard focuses on the short-wavelength UV region that is most responsible for polymer degradation.

A typical ASTM G154 test alternates between two core phases:

UV exposure, simulating the damaging effects of sunlight

Condensation exposure, simulating moisture stress caused by dew and nighttime humidity

This cyclic approach accelerates aging while maintaining a strong correlation with real-world performance. As a result, ASTM G154 is widely used for plastics, coatings, elastomers, and composite materials across multiple industries.

The standard defines different test cycles and lamp types to suit various evaluation objectives. UVA-340 lamps closely match the UV portion of natural sunlight and are commonly used for durability prediction, while UVB-313 lamps generate shorter wavelengths for more aggressive accelerated screening.

From a compliance perspective, ASTM G154 places strict demands on the testing equipment. Stable UV irradiance, precise temperature control, reliable condensation formation, and long-term repeatability are not optional—they are fundamental to obtaining meaningful and comparable results. This is where the performance of the UV chamber becomes decisive.

Environmental Chamber For Accelerated Aging Testing | |

uv accelerated weathering tester | |

This solution is designed for laboratories and manufacturers that require consistent, defensible UV aging data. It is not simply a light exposure box, but a fully integrated system that combines UV irradiation, thermal control, and condensation simulation into a single, coordinated testing environment.

Typical users include material testing laboratories, third-party certification bodies, and manufacturers performing internal durability validation before market release.

Stable UV Irradiance Control

The chamber uses fluorescent UV lamps compatible with ASTM G154 requirements, with programmable irradiance control to maintain stable output throughout long-term tests. Compensation mechanisms reduce the impact of lamp aging, ensuring that exposure conditions remain consistent from the first cycle to the last.

Independent Temperature Control for Each Phase

Temperature during UV exposure and condensation phases is independently controlled. This separation minimizes thermal interference between phases and allows accurate reproduction of ASTM-defined test conditions, improving the relevance of aging results.

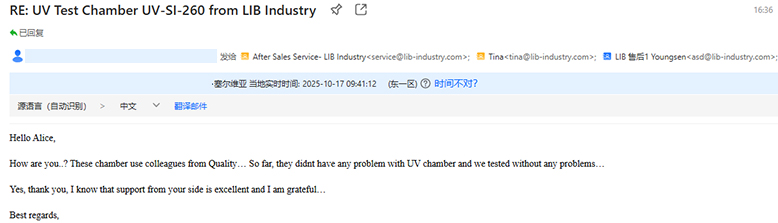

Condensation Simulation System

Instead of simple humidity control, the system creates stable surface condensation on test specimens. This approach more accurately reproduces moisture-driven degradation mechanisms such as hydrolysis, coating delamination, and surface discoloration.

Every core function of the chamber is designed to support the repeatability and comparability demanded by ASTM G154.

Uniform Exposure for Multi-Sample Testing

Optimized airflow design and sample arrangement ensure that all specimens receive consistent UV and thermal exposure. This is essential when testing multiple samples simultaneously or comparing material formulations.

High-Precision Sensors and Industrial Components

Temperature and irradiance are monitored by high-accuracy sensors, while industrial-grade components support long-duration operation. This design minimizes parameter drift during extended aging programs.

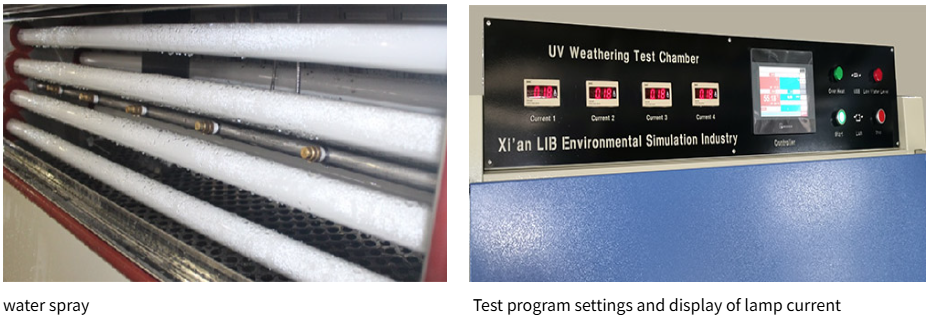

Programmable and User-Friendly Control System

The controller allows users to easily configure different ASTM G154 test cycles, including exposure duration, temperature setpoints, and condensation intervals. Automation reduces operator error and improves test efficiency.

|  |

Model | UV-SI-260 |

Internal Dimension (mm) | 450*1170*500 |

Overall Dimension (mm) | 680*1300*1500 |

Irradiation Source | Fluorescent UV lamps (8) - 40 W |

Temperature Range | Ambient ~ 90 ℃ ±2℃ |

Black Panel Temperature (BPT) | 35 ~ 80 ℃ |

Humidity Range | ≥95% RH |

Bandwidth | 290 ~ 400nm |

Irradiance Control | 0.3~20 W/㎡ |

Distance of Specimen and lamp | 50mm |

Heating Element | Nichrome heater |

Controller | Programmable color LCD touch screen controller |

Ethernet connection, PC Link, USB | |

Water Supply System | Automatic water supply, Water purification system |

Interior Material | SUS304 stainless steel |

These measurable parameters provide laboratories and engineers with the confidence needed for both internal evaluation and external compliance reporting.

Recognizing that testing requirements vary by material and application, LIB industry offers extensive customization options. Sample racks, chamber configurations, and control logic can be adapted to specific specimen sizes, testing volumes, or internal laboratory workflows. This flexibility allows users to implement ASTM G154 testing efficiently without compromising standard compliance.

The ASTM G154 UV Chamber solution by LIB industry allows laboratories and manufacturers to perform accelerated UV aging tests fully compliant with ASTM G154 standards. A typical workflow combines precise control, repeatable cycles, and standard-specified conditions:

Sample Mounting on Dedicated Racks

Test specimens are placed on specially designed racks to ensure uniform exposure to UV radiation and condensation.

ASTM G154 specifies that samples must be arranged so that each surface receives consistent irradiance and airflow, preventing uneven aging.

Selection of ASTM G154 Test Cycle

Using the programmable control system, the operator selects the appropriate cycle based on the material type and test objective.

Standard-compliant cycles define UV exposure duration, lamp type (UVA-340 or UVB-313), temperature setpoints, and condensation periods to simulate realistic weathering.

UV Exposure Phase

Specimens are irradiated under controlled intensity and temperature conditions.

ASTM G154 requires maintaining UV irradiance within ±10% of the target value to ensure repeatable and comparable results. The LIB industry chamber automatically compensates for lamp aging to maintain stability throughout long-term tests.

| Feature | UVA-340 | UVB-313 |

|---|---|---|

| Spectrum | Closest to natural sunlight (295–365 nm) | Short-wave, high-energy UV |

| Test Purpose | Realistic aging, color fastness, polymer degradation prediction | Rapid screening, high-resistance material selection, QC |

| Recommended Materials | Coatings, plastics, inks | Extreme weathering plastics, automotive parts |

| ||

Condensation Phase

Following UV exposure, samples undergo condensation cycles that simulate dew or high humidity conditions.

The standard specifies the condensation temperature and duration for each cycle. LIB industry chambers maintain precise thermal control to generate stable moisture on the sample surfaces without oversaturation.

Cycle Repetition

The UV exposure and condensation phases are repeated for the total number of cycles required by the test protocol.

Continuous monitoring ensures that environmental parameters do not drift over time, meeting ASTM G154’s demand for reproducibility over extended durations.

Post-Test Evaluation

After completing all cycles, samples are assessed for visual changes, mechanical property variation, or chemical degradation.

Because the chamber ensures uniform, controlled, and repeatable exposure, the results are directly comparable across samples and test runs, providing reliable data for product development or quality assurance.

Throughout the entire process, the LIB industry ASTM G154 UV Chamber maintains stable irradiance, temperature, and condensation conditions. This level of control ensures that accelerated UV weathering tests not only comply with the standard but also deliver meaningful, actionable insights for material durability and product performance.

Can multiple samples be tested simultaneously?

Yes. The chamber is designed to support multi-sample testing with consistent exposure conditions.

How is long-term irradiance stability ensured?

UV output is continuously controlled and adjusted to minimize the effects of lamp aging over time.

What is the lifespan of the UV lamps?

The UV lamps in our chambers now provide a long-lasting 5000 hours of reliable operation. This extended lifespan reduces maintenance and downtime, ensuring consistent performance for your accelerated UV weathering tes

What is the distance between lamps, and why does it matter?

The lamps are spaced optimally at approximately 5 cm, following ASTM G154 guidelines. This arrangement guarantees uniform UV distribution, ensuring that every surface of your samples is evenly exposed for highly reliable weathering results.

Does the UV chamber have a water system, and can water be reused?

Yes. The chamber includes a smart water supply and filtration system, maintaining clean water for high-humidity cycles. Excess water is automatically recycled, ensuring continuous operation, improved efficiency, and minimal water waste.

Ensure your materials and products withstand long-term UV exposure with the ASTM G154 UV Chamber solution by LIB industry.

LIB industry offers full support and customization for every UV Chamber:

Warranty & Service: 3-year warranty and lifetime technical support

Installation & Training: On-site setup and comprehensive user guidance

Custom Configurations: Sample racks, chamber volume, and control programs tailored to your testing needs

Contact LIB industry today at inquiry@libtestchamber.com for a personalized consultation and discover how our ASTM G154 UV Chamber solution can revolutionize your accelerated UV weathering tests.