Military and industrial-grade equipment must perform reliably in extreme environments. To ensure durability against rain, humidity, and water intrusion, the MIL-STD-810H Method 506.6 standard outlines how to test equipment under simulated rain conditions to evaluate water resistance, sealing, and operational integrity.

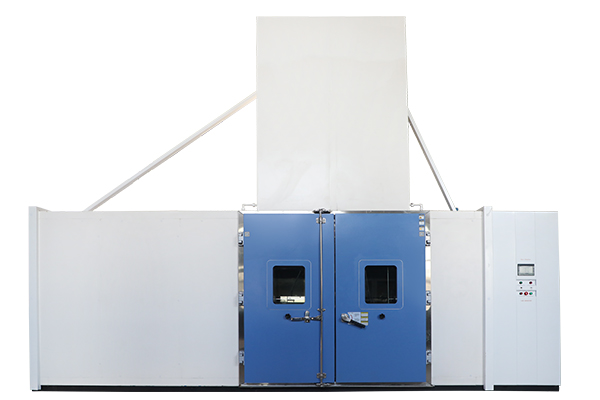

MIL-STD-810H's Rain Method comprises 3 procedures, each replicating a different environmental scenario.LIB MIL-STD-810H Rain Chamber can conduct three kinds of tests

Objective: Simulate rain driven by wind to evaluate the water-tightness of enclosures and the equipment's ability to operate during or after exposure.

Rainfall Rate: 1.7 mm/min (±0.5 mm/min)

Wind Speed: 18 m/s (±10%)

Water Temperature: 18°C to 27°C

Test Duration: Minimum 30 minutes per face (4 faces recommended)

Nozzle Distance: 1.5 m from test item

Applications: Outdoor electronics, sensors, vehicle-mounted gear.

This procedure assesses how well equipment can resist wind-driven rain intrusion, especially at connection points, seams, and vents.

Objective: Test the resistance of materials and devices to high-intensity rain in areas of high rainfall or tropical environments.

Key Parameters:

Rainfall Rate: 280 mm/h (±10%) – much heavier than Procedure I

No Wind Simulation

Test Duration: 30 minutes per orientation (usually 4 orientations)

Height of Drip Source: 1 meter above the device

Applications: Equipment installed in fixed positions where heavy downpours may occur (e.g., radars, base station gear).

This procedure focuses on water ingress due to gravity-driven rainfall and helps identify vertical leakage paths.

Objective: Simulate water dripping onto equipment due to condensation or minor leaks in enclosures (e.g., shelters, cargo holds).

Key Parameters:

Drip Rate: 140 L/m²/h

Drip Height: 1 m above the equipment

Duration: 15 minutes per face

Device Temperature: Above ambient to promote condensation behavior

Applications: Handheld devices, portable electronics, equipment used in covered but humid/wet environments.

This is the least aggressive method but crucial for portable and semi-indoor devices susceptible to minor water exposure.

LIB offers customizable rain test chambers designed to simulate all three MIL-STD-810H rain procedures within a single unit or tailored to specific steps. Whether you're testing wind-driven rain intrusion or vertical drip resistance, our chambers deliver:

Adjustable rainfall intensity and droplet size

Integrated wind simulation system up to 20 m/s

Precise nozzle placement and test duration control

Real-time monitoring and programmable test cycles

With LIB’s MIL-STD-810H compliant test chambers, manufacturers can confidently assess their product’s water ingress protection and ensure compliance with military and industrial standards.Contact LIB today to configure your MIL-STD-810H Rain Test Chamber.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia