Outdoor products face constant exposure to sunlight, heat, humidity, and rainfall, which gradually cause fading, cracking, and surface degradation. Ensuring long-term color and material stability has become a critical challenge for manufacturers of coatings, plastics, textiles, and automotive components. Accelerated weathering tests provide insight into how products will perform over time, helping businesses reduce material failures, warranty claims, and customer dissatisfaction.

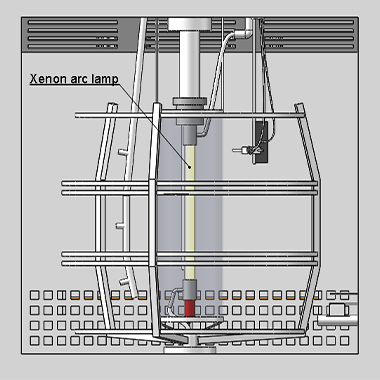

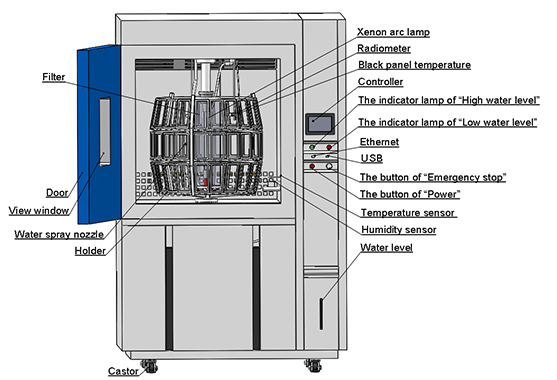

To simulate these real-world aging effects under controlled laboratory conditions, the Xenon Weather Resistance Test Chamber from LIB industry provides the most accurate sunlight reproduction system available. By using high-intensity xenon arc lamps, the xenon test chamber delivers a full-spectrum light source that replicates UV, visible, and infrared radiation, enabling precise and repeatable durability testing while mimicking actual environmental conditions.

|

|

A xenon arc chamber reproduces the spectral distribution of natural sunlight, covering wavelengths from 290 to 800 nm. The system exposes materials to cycles of light, temperature, humidity, and water spray or condensation to accelerate weathering effects. Its programmable controller automatically regulates these parameters with exceptional precision, enabling long-term reliability studies, comparative material evaluations, and accelerated aging simulations.

|

|

Name | Xenon Weather Resistance Test Chamber |

Model | XL-S-750 |

Specimen Holder Size(mm) | 95*200 |

Specimen Capacity | 42pcs |

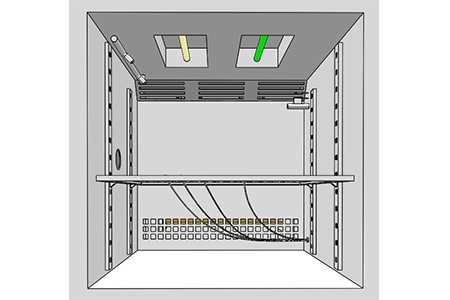

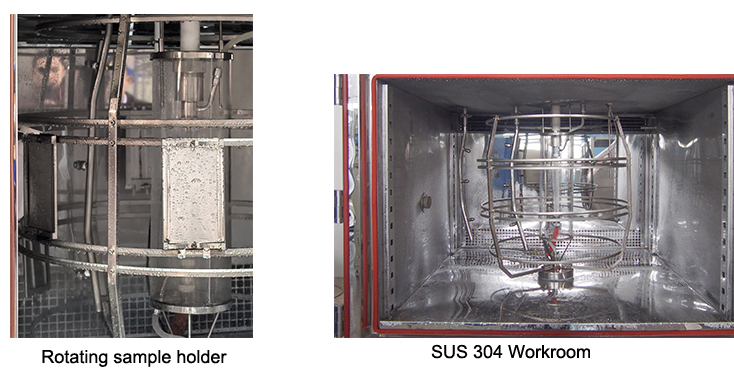

Chamber Type | Rotating Holder |

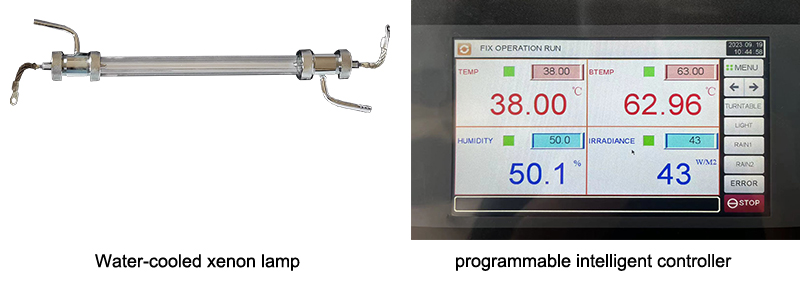

Irradiation Source | 1 piece of 4500w water-cooled xenon arc lamp |

Irradiance Range | 35~150 W/㎡ |

Bandwidth Measurement | 300nm~400nm (340nm or 420nm) |

Chamber Temperature Range | Ambient ~ 100 ℃ ±2℃ |

Black Panel Temperature | BPT 35 ~ 85 ℃ ±2℃ |

Humidity Range | 50% ~ 98% RH |

Water Spray Cycle | 1~9999H59M (Adjustable) |

Controller | Programmable color LCD touch screen controller |

Water supply system | Automatic water supply, Water purification system |

Radiometer | UV Radiometer, Tolerance: ±5% |

Cooling System | Mechanical compression refrigeration system |

Xenon Light Fastness Test Chamber Accelerated Weather Tester(Xenon) You May Interested In: | |

High-intensity xenon lamps reproduce full-spectrum light energy distribution, ensuring accurate evaluation of color retention, gloss, and surface integrity.

The advanced touchscreen interface allows users to create customized test profiles, monitor data in real-time, and implement automatic safety shutdowns. Parameters such as irradiance, temperature, and humidity are precisely regulated via PID control loops.

The xenon weather resistance chamber’s air circulation and refrigeration systems maintain stable temperature and humidity, while uniform light distribution ensures all test samples experience consistent exposure.

The SUS304 stainless steel workroom is corrosion-resistant, insulated, and designed for long-term durability. Multi-layer safety systems include over-temperature protection, low water level alarms, and electrical leakage prevention.

LIB industry provides tailored chamber sizes, lamp configurations, test profiles, and optional water or condensation systems, allowing customers to meet specialized testing requirements and industry standards.

| Walk in xenon test chamber |

| Combination of xenon lamps and halogen lamps |

| Custom sample holder |

Standards Compliance: Fully conforms to ISO 4892-2, ASTM G155, SAE J2527 and JIS B7753, ensuring global applicability and acceptance in professional laboratories.

Automotive Components and Coatings

Test exterior panels, headlights, trims, and coatings for UV exposure, color fading, gloss retention, and cracking. This ensures vehicles maintain aesthetic and functional quality over time.

Applicable Standards: ISO 105-B02, SAE J2527, ASTM D750, ASTM G155.

Plastics and Polymers

Assess material color retention, mechanical strength, and surface stability under accelerated light, heat, and humidity exposure.

Applicable Standards: ISO 4892-2, ASTM D2565, ISO 179, ASTM D4459.

Paints and Coatings

Evaluate chalking, gloss retention, adhesion, and photochemical degradation for industrial coatings.

Applicable Standards: ISO 2810, ISO 11341, ASTM D6577, ASTM D4587.

Textiles and Fabrics

Test colorfastness and fading resistance under simulated sunlight and moisture cycles, critical for fashion and technical fabrics.

Applicable Standards: ISO 105-B02, AATCC TM16, JIS L0843.

Electronics and Packaging

Ensure coatings, labels, housings, and packaging materials remain stable and maintain functionality under UV and temperature cycles.

Applicable Standards: IEC 60068-2-5, ISO 4892.

(Each application may also utilize the system as a xenon light fastness test chamber to ensure consistent optical stability across materials.)

Q1: How does LIB industry ensure accurate UV exposure in testing?

A1: The chamber uses calibrated radiometers and automatic irradiance adjustment to maintain precise energy output, ensuring reproducible results.

Q2: Can the chamber simulate different environmental conditions?

A2: Yes, selectable optical filters allow simulation of outdoor, indoor, or behind-glass conditions, combined with programmable temperature and humidity cycles.

Q3: How is long-term data reliability maintained?

A3: Integrated sensors continuously record temperature, humidity, and irradiance trends. Regular lamp replacement, calibration, and maintenance ensure consistent exposure across extended testing cycles.

LIB industry combines decades of experience with advanced engineering to deliver xenon weather resistance test chambers that set industry standards. Every system is fully customizable, energy-efficient, and built to meet global testing requirements. By partnering with LIB industry, manufacturers gain access to cutting-edge technology, professional guidance, and tailored solutions that accelerate product development, improve durability, and reduce material failures.

3-year warranty and lifetime technical support

Fast delivery: 7–15 days from order to shipment

Global service points ensuring rapid on-site assistance

1 to 3-hour rapid response

Contact LIB industry today inquiry@libtestchamber.com to learn more about advanced xenon weathering technology and obtain more details and and take your product durability testing to the next level.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia