A leading battery manufacturer contacted LIB industry seeking high-precision temperature and humidity chambers for Li-ion battery cells. The requirements were ambitious: humidity range of 10%–98% RH, workroom capacity of 50–60 L, and temperature from +30 ℃ to +150 ℃. Given the volatility of batteries at high temperatures, safety and reliability were top priorities.

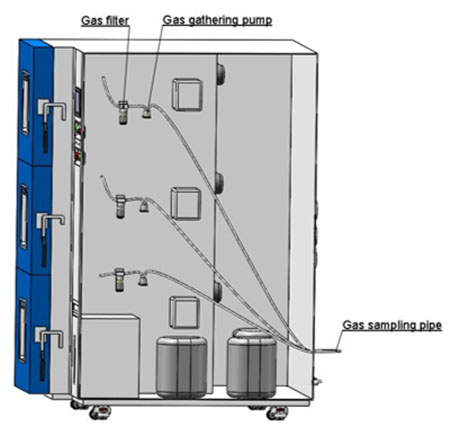

By December 2023, LIB successfully delivered three vertically stacked TH-100B3 chambers, each independently controllable and fully equipped with explosion-proof features, marking a significant milestone in battery R&D testing.

Unlike conventional single-unit chambers, the TH-100B3’s vertical stack configuration maximizes lab space while maintaining full functionality:

· Three Independent Workrooms: Each layer can operate at different temperatures and humidity settings.

· Compact Footprint: Saves floor space while supporting multiple tests simultaneously.

· Test Ports: Each workroom includes a 50 mm diameter port for probes or sensors without affecting environmental conditions.

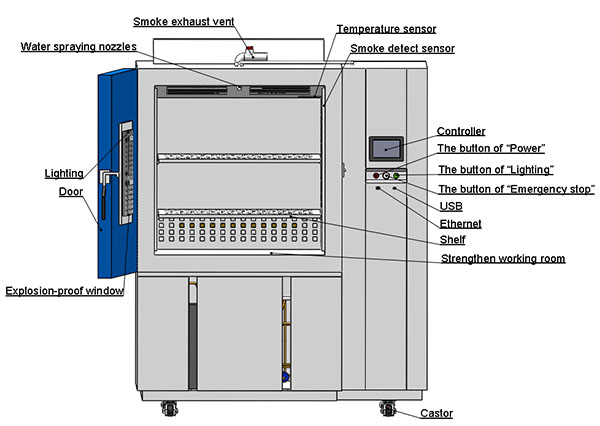

The TH-100B3 is built on the core architecture of a standard temperature and humidity test chamber, featuring stable temperature control, precise humidity regulation, uniform airflow, and durable SUS304 stainless-steel construction. This ensures long-term reliability, accurate test repeatability, and consistent environmental performance.

For battery testing applications, LIB industry enhances this standard chamber platform with additional explosion-proof reinforcements, fire suppression systems, and multi-layer safety mechanisms, transforming it into a secure solution suitable for Li-ion battery cell evaluation.

Feature | Specification | Benefit |

Temperature Range | +30 ℃ to +150 ℃ | Accurate, repeatable thermal stress testing |

Humidity Range | 10%–98% RH | Supports various battery test protocols |

Workroom Capacity | 50–60 L per chamber | Accommodates multiple cells per unit |

Explosion-Proof Design | Yes | Reinforced workrooms, doors, observation windows, and locks |

Fire Safety Systems | Smoke alarm, exhaust, fire extinguisher | Enhanced safety during high-temperature operation |

Independent Workroom Control | 3 workrooms | Fully customizable temperature and humidity for each layer |

Test Ports | 3 × 50 mm diameter | Safe probe insertion without disrupting tests |

|  | |

Each stacked TH-100B3 integrates explosion-proof workrooms, reinforced observation windows, secure locks, smoke alarms, exhaust systems, and fire extinguishers, ensuring operator safety and reliable battery testing under extreme conditions.In addition to the custom temperature and humidity test chambers for testing batteries, LIB industry also offers standard models of battery test chambers.

|  |

The vertical stack design not only saves lab space but also enables simultaneous multi-condition testing. Researchers can now conduct faster, more efficient experiments while maintaining complete environmental control for each test unit.

LIB industry provides more than chambers—we offer a full-service ecosystem:

· Custom Sample Holders: Tailored fixtures for batteries of varying sizes.

· Rapid Spare Parts Delivery: Critical components shipped globally within 7–15 days.

· Comprehensive After-Sales: 36-month warranty, lifetime technical support, 24/7 English service, remote troubleshooting within 12 hours, on-site engineer support when needed.

· Export-Standard Packaging & Logistics: Durable crates and optimized routes ensure safe, on-time delivery worldwide.

For customized, high-precision temperature and humidity chambers for Li-ion batteries or other advanced materials, LIB industry provides:

· Compact, vertically stacked chambers with independent control

· Robust safety systems and flexible testing workflow

· Comprehensive global support and rapid spare parts

Contact LIB industry today inquiry@libtestchamber.com to discover how TH-100B3 can transform your R&D and quality assurance processes.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia