Material durability and reliability are critical in industries ranging from automotive and electronics to marine engineering. Selecting the wrong corrosion test can lead to unexpected material failures, costly recalls, or wasted R&D efforts. Understanding the differences between ASTM B117, electrochemical corrosion testing, and humid heat testing is essential for making informed decisions.

ASTM B117 uses a 5% NaCl solution atomized into a salt spray to expose the sample. Chloride ions attack the metal surface, destroying passivation films and triggering corrosion reactions.

Conducted in a salt spray chamber at 35°C, with a sedimentation rate of 1–2 ml/80 cm²·h, test durations range from a few hours to thousands of hours depending on material resistance.

|  |

Applications: Ideal for steel, aluminum, zinc, and coated metals. Widely used in automotive, marine, and electronics industries to simulate salt-laden atmospheres.

- High standardization enables strong comparability across labs.

- Equipment is simple and low-cost, supporting large-scale material screening.

- Limited simulation of real-world conditions like variable humidity or pollutants.

- Long test cycles, especially for highly resistant materials.

- Focuses on macroscopic corrosion observation rather than detailed mechanisms.

Tip: ASTM B117 is best for preliminary screening of metallic coatings in chloride-rich environments.

The sample serves as a working electrode in an electrochemical cell, with a reference electrode (e.g., saturated calomel) and auxiliary electrode (e.g., platinum). Measuring the polarization curve allows calculation of corrosion current density, passivation potential, and other parameters.

Requires an electrochemical workstation, electrodes, and controlled electrolytes like 3.5% NaCl. Temperature and stirring can be adjusted to simulate specific environments.

Applications: Ideal for detailed corrosion mechanism studies, evaluating coatings, and optimizing surface treatments in metals. Common in R&D, failure analysis, and protective coating design.

- Rapid and precise evaluation of corrosion rates.

- Provides microscopic insight into passivation and corrosion dynamics.

- Flexible parameters allow simulation of diverse working conditions.

- Sensitive to sample surface quality and preparation.

- Accuracy depends on electrolyte composition, temperature, and instrument calibration.

- Limited for complex or multiphase materials.

Tip: Electrochemical testing is essential when precise corrosion kinetics and mechanism insights are needed.

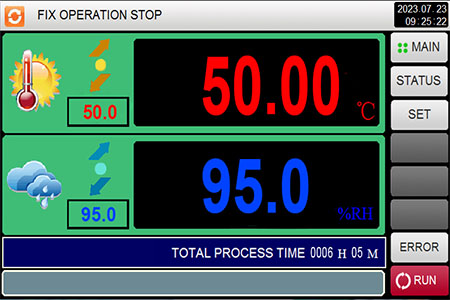

Samples are exposed to high temperature and humidity (generally 40–60°C and >90% RH) in temperature humidity environmental chamber to form a water film on the surface, accelerating chemical reactions and material aging.

|

|

Applications: Suited for electronic components, organic materials, and certain metals. Widely used to ensure reliability of circuit boards and sensitive electronics in hot, humid environments.

- Simulates actual humid environments better than dry tests.

- Easy operation and low cost.

- Allows simultaneous observation of corrosion, aging, and property degradation.

- Single-environment simulation; cannot reproduce salt spray or industrial pollutants.

- Limited electrochemical insight, focusing mainly on macroscopic property changes.

Tip: Use humid heat testing to validate durability of moisture-sensitive products under tropical or high-humidity conditions.

Test Method | Duration | Accuracy | Applications | Pros | Cons |

ASTM B117 | Hours → Thousands of hours | Macro | Metals, coatings | Standardized, low-cost | Long cycles, limited mechanism insight |

Electrochemical | Hours → Days | Micro + Macro | Metals, coatings | Fast, mechanistic insight | Sensitive to prep, limited for complex systems |

Humid Heat | Days → Months | Macro | Electronics, organics | Realistic humid conditions, low-cost | Single environment, limited electrochemistry |

Selecting a corrosion test depends on material type, intended environment, and research purpose:

- Metals & coatings exposed to marine or salt environments: ASTM B117 for preliminary screening.

- Precise corrosion rates and mechanism studies: Electrochemical testing is ideal.

- Electronics and moisture-sensitive products: Humid heat testing ensures reliable performance.

Case in Point:

- Automotive OEMs use ASTM B117 to pre-screen coatings, reducing corrosion failures by 30%.

- Electronics manufacturers rely on humid heat testing to ensure circuit boards withstand tropical climates.

Ensure your components, coatings, and electronics withstand real-world corrosion stress. LIB industry provides ASTM B117, electrochemical, and humid heat testing with fast turnaround, expert guidance, and customizable solutions.

Contact us at inquiry@libtestchamber.com for a free consultation and tailored test plan today.

Fast delivery | Custom configurations | 3-Year Warranty | Lifetime Support

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia