Lithium-ion batteries have become ubiquitous in consumer electronics, electric vehicles, energy storage systems, and industrial applications. As energy density increases and battery applications expand, temperature stability and environmental reliability are critical to ensure performance, longevity, and safety. LIB industry provides a full spectrum of temperature testing solutions, including dedicated Li-ion battery temperature test chambers, temperature test chambers and thermal shock chambers, designed to meet all your battery testing needs.

Lithium-ion batteries are highly sensitive to thermal conditions. Without rigorous testing, batteries may experience:

- Capacity decay and accelerated aging at high or low temperatures

- Lithium plating and reduced efficiency under low-temperature operation

- Electrolyte evaporation, swelling, and gas generation under high temperatures

- Structural deformation and safety risks due to rapid thermal changes

A professional temperature test chambers ensures repeatable, precise, and safe evaluation of battery performance under a variety of thermal conditions, preventing costly failures and ensuring compliance with industry standards.

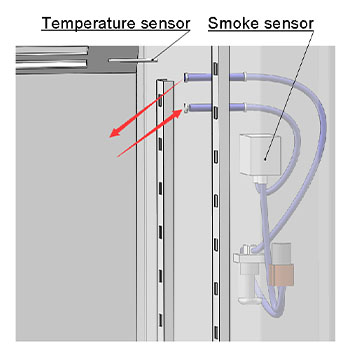

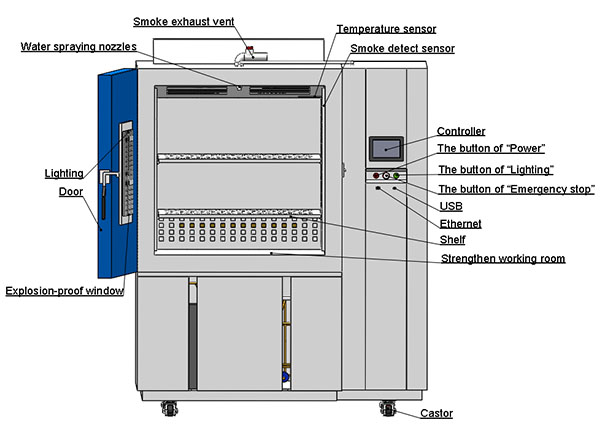

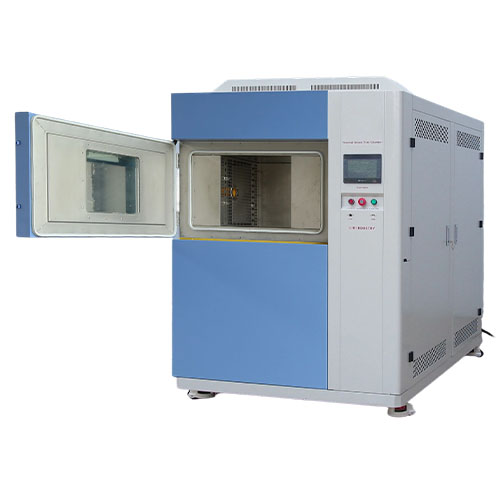

- Explosion-proof design with integrated fire-suppression system ensures safety during high-temperature testing

- Temperature range −70°C to +170°C, with customizable thermal profiles

- Precision control: ±0.5°C fluctuation / ±2.0°C deviation

- Fast heating/cooling: 10°C/min average for rapid thermal cycling

- Large-volume test space accommodates single cells, modules, or multiple batteries

- Real-time monitoring, automated data recording, and export for post-test analysis

|

|

|  |

These chambers offer stable temperature control for long-term storage and operational tests:

- Simulate extended low- or high-temperature storage conditions

- Assess capacity retention, charge/discharge efficiency, and internal resistance

- Provide large test volumes for batch testing of cells and modules

- Customizable temperature ranges and heating/cooling rates

- Supports continuous 24/7 operation for reliability testing

|  |

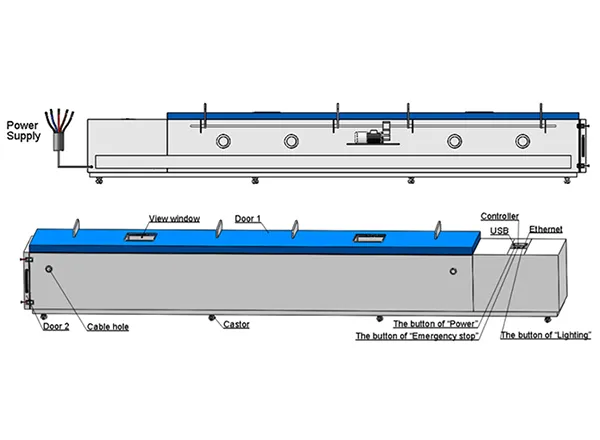

Rapid temperature transitions are critical to assess battery structural integrity and thermal resilience:

- Cycle batteries between extreme temperatures (e.g., −40°C to +80°C)

- Detect mechanical deformations, electrode or separator damage, and shell integrity issues

- Measure performance and capacity after each shock cycle

- Accelerated thermal shock testing supports safety and certification requirements

|  |

A low-temperature limit (e.g., −20°C) is set and the battery is stored for 4–8 hours. After returning to 25°C for 2 hours, capacity, charge/discharge efficiency, internal resistance, lithium plating and gas presence are evaluated.

At 55–65°C, batteries are exposed for 4–6 hours. Afterwards, low-temperature parameters are re-measured to observe electrolyte evaporation, capacity fade, electrode dissolution and internal resistance rise.

The chamber cycles through 0°C → 40°C → −20°C → −60°C, each stage held for 2–3 hours. The test is repeated for 5–10 cycles to assess material durability, structural stability, and performance fluctuation under temperature shocks.

Batteries are placed at −40°C for 2–3 hours, then quickly shifted to +80°C for 2 hours. This 3–5-time sequence evaluates mechanical integrity of electrodes, separators, and housing under rapid temperature transitions.

Many of the above test procedures align with established international battery safety and transport test standards — such as UN 38.3 (Thermal Test / Temperature Cycling) and IEC 62660-2 for performance and reliability testing.

Under UN 38.3 Thermal Test, for instance, cells or batteries must endure repeated high-low temperature cycles (e.g. +72°C ↔ –40°C), dwell times ≥6 hours, with conversion time between extremes ≤30 minutes, over 10 cycles — then rest 24h at ambient temperature. After test, samples must exhibit no leakage, venting, disassembly, rupture or fire, and their open circuit voltage (OCV) must remain within specified limits.

For battery performance and reliability testing (e.g. under IEC 62660-2), testing may include capacity discharge and endurance tests at varied temperatures, temperature cycling, and high-temperature endurance tests to evaluate long-term stability.

Thanks to its wide temperature range (−70°C to +170°C), fast and precise thermal control, and programmable cycling capabilities, LIB industry’s thermal chambers are fully capable of running both standard-compliant protocols and customized test sequences — making them suitable for certification labs, R&D departments, automotive battery labs, and quality control departments.

- One-Stop Temperature Testing Solutions:

From basic temperature tests to humidity cycling and rapid thermal shock, LIB provides all types of chambers to meet any battery testing requirement.

- Safety-First Engineering:

Explosion-proof structures and fire-suppression systems eliminate operational risks.

- Customizable Configurations:

Temperature ranges, humidity levels, heating/cooling rates, and chamber sizes can be tailored for specific battery formats and test protocols.

- Reliable Continuous Operation:

Designed for 24/7 use in R&D labs, production lines, and certification facilities.

- Proven Track Record:

Trusted by global battery manufacturers, automotive suppliers, and independent testing labs.

LIB industry offers full-spectrum temperature testing solutions for Li-ion batteries with expert engineering support, high-precision performance, and safety-focused design.

- Full range of chambers: temperature, temperature & humidity, thermal shock

- Custom test programs and chamber configurations

- Fast delivery and on-site technical support

- 3-year warranty & lifetime service for peace of mind

Take the next step in battery testing:

Send your testing requirements to inquiry@libtestchamber.com

Our engineers provide tailored solutions and quotations within 1~3 hours, helping you implement safe, accurate, and comprehensive battery testing.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia