LIB announced today that following the successful customization of the T-1000B, T-1000B and TR3-500B (split type) series equipment for Nidec, the two sides have deepened cooperation once again and delivered the TH-0098 giant temperature and humidity test chamber with a volume of up to 98 m³, significantly enhancing the batch quality inspection efficiency of the customer's motor products.

The TH-0098 temperature humidity test chamber is specially designed to meet the strict quality inspection requirements of a large number of motor products at Nidec's Vietnam factory. Faced with an unprecedented scale of space (0°C to 90°C, 20% to 98% RH, thermal load 6KW) and the complexity of coordinating with the customer's site, the LIB project team demonstrated outstanding engineering adaptability.

Before finalizing the solution, the LIB team visited the customer's laboratory in Vietnam twice for on-site surveys and carefully optimized the design plan to ensure that the equipment perfectly fits the actual application scenario.

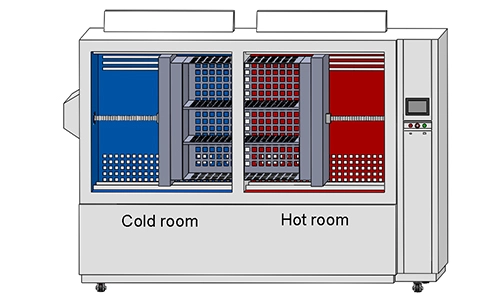

This large-scale test chamber is custom-made with 24 test cables. Its internal working space can easily accommodate over ten carts fully loaded with motors, enabling the simultaneous operation and testing of thousands of motors, and supporting multiple batches of parallel experiments. As a key part of the factory's quality inspection process, each batch of motors needs to undergo continuous testing for up to 72 hours. The successful commissioning of the TH-0098 has replaced the customer's previously scattered multiple small test chambers, raising the quality inspection efficiency to a new level.

Due to the large size of the equipment, LIB adopted a modular split design:

Precise disassembly for transportation: Based on the customer's site conditions (such as elevator size, laboratory entrance size, etc.), the test chamber is scientifically decomposed into transportable modules and numbered. The refrigeration unit is divided into two independent modules as a whole.

On-site "building blocks" reassembly: At the customer's site, the technical team strictly assembles the high-strength A3 steel plate shell and SUS 304 stainless steel inner wall layer by layer according to the module numbers, starting from the load-bearing base plate.

Strict sealing and cleaning: Professional sealing and welding techniques are used for the split seams to ensure the ultimate sealing of the working chamber. Rust generated during installation is thoroughly removed with a special weak acid cleaner to ensure internal cleanliness and aesthetics.

Double humidification guarantee: To meet the wide range of humidity requirements (20% to 98% RH) in the large space, in addition to the standard electric humidification system, a microwave humidification system is specially added to ensure precise and stable humidity control. The entire installation process strictly follows safety regulations.

After the equipment installation is completed, LIB engineers provide on-site system training to the Nidec operation team and complete the connection of water and electricity. After strict testing, the temperature and humidity control parameters are precise, and all indicators meet the design expectations. The project is successfully delivered.

The TH-0098 project once again validates LIB's core capabilities - starting from the client's initial vague concept, and relying on its profound experience in the design, manufacture, transportation and installation of large-scale equipment, it ultimately delivers a fully functional, efficient and reliable "turnkey" laboratory solution. LIB is committed to being the most trusted partner for customers in the field of complex environment testing.

The successful implementation of TH-0098 not only solidifies the strategic partnership between LIB and Nidec, but also highlights LIB's leading position and professional expertise in designing and delivering highly customized environmental testing equipment of extreme scale.

LIB is a leading provider of environmental testing equipment and solutions, specializing in designing, manufacturing and delivering high-performance and highly reliable temperature and humidity test chambers, rapid temperature change test chambers and other customized environmental simulation chambers climate simulation equipment for high-end manufacturing customers worldwide.

From concept to commissioning, LIB delivers performance you can trust. Let’s build your next testing solution—together. Contact us at inquiry@libtestchamber.com,tell you about your requirements.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia