Riding the Industry Wave

With the rapid growth of new energy vehicles and autonomous driving technologies, critical components such as sensors, battery packs, and connectors face unprecedented exposure to harsh road environments. Water intrusion, high-pressure sprays, and temperature fluctuations can compromise reliability, posing real-world risks that extend beyond regulatory compliance.

Standard Spotlight

ISO 20653, the international standard for road vehicle protection levels, raises the bar far beyond the familiar IEC 60529. Among its levels, IPX9K represents the ultimate stress test: high-pressure, high-temperature, multi-angle spray—conditions that can expose even minor design flaws in seals and housings.

The Real Value of Testing

The goal of rigorous IPX9K testing is not merely to obtain a certificate—it is to mitigate failure risks before they reach the road. In other words, a test that simulates real-world extremes ensures safety, durability, and product confidence for automotive-grade components.

| Parameter | IPX9K Requirement |

|---|---|

| Pressure | 8,000 – 10,000 kPa (≈80–100× atmospheric pressure) |

| Flow Rate | 14 – 16 L/min |

| Water Temperature | 80 ± 5°C (instant thermal shock) |

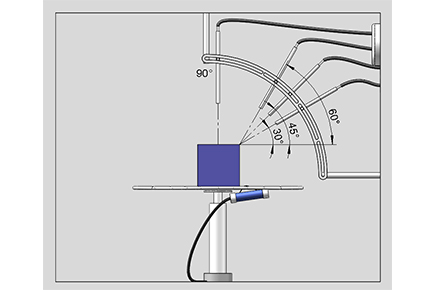

| Spray Angles | 0°, 30°, 60°, 90° (cycled) |

Technical Pain Points

Why can’t ordinary test chambers achieve IPX9K compliance?

Pressure instability leads to inconsistent spray force, failing to stress test seals effectively.

Temperature inaccuracies accelerate or underrepresent aging of elastomers, providing false confidence.

Angle cycling precision is critical to ensure uniform exposure across complex geometries.

|  |

LIB Industry’s IPX9K test chamber solves these problems with robust engineering and high-precision control.

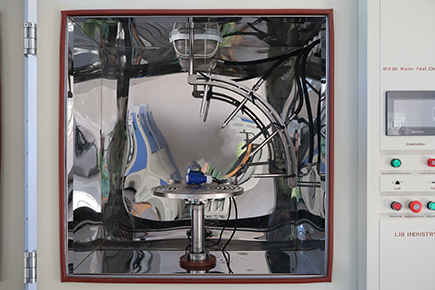

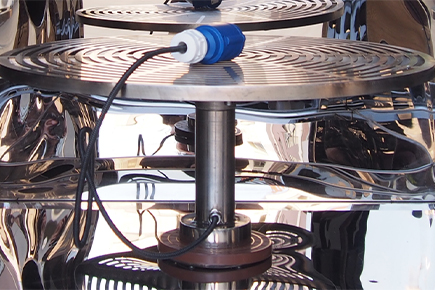

Step 1: Test Specimen Installation & Spatial Adaptation

Practical Detail: Engineers mount components like motors or battery packs onto a rotary platform.

IPX9K Test Equipment Advantage: LIB offers customizable platform sizes and load-bearing solutions. Adjustable spray stands ensure the nozzle-to-specimen distance stays within the ISO-mandated 100–150mm range, even for irregularly shaped components.

|  |

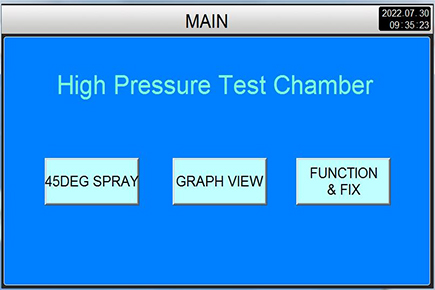

Step 2: One-Click Parameter Preset (Compliance Assurance)

Practical Detail: Selecting “IPX9K mode” on the control panel automatically sets water temperature to 80°C, pressure to 8–10 MPa, and flow rate to 14–16 L/min.

IPX9K Test Equipment Advantage: Built-in ISO 20653 instructions eliminate manual conversion errors, ensuring standardized, repeatable testing.

|  |

Step 3: Stable High-Temperature, High-Pressure Output (The Test Core)

Practical Detail: Four spray nozzles cycle through 0°, 30°, 60°, and 90° angles, each position lasting 30 seconds.

IPX9K Test Equipment Advantage:

Temperature Stability: Independent heat-exchange system keeps water within ±5°C.

Pressure Consistency: Variable-frequency high-pressure pumps prevent pressure drops during nozzle switching.

Observation Convenience: Heated anti-fog glass and integrated wipers allow real-time monitoring of specimen surface for damage.

|  |

Step 4: Data Closure & Report Generation

Practical Detail: After spraying, the system drains and cools automatically.

IPX9K Test Equipment Advantage: Temperature, pressure, and timing curves are stored in the controller and can be exported via USB or network. Data is tamper-proof, meeting laboratory quality management standards.

Practical Scenarios:

New Energy Battery Packs: Customized platforms support large-scale specimens.

Autonomous Driving Cameras: Verify optical sealing under high-temperature, high-pressure conditions.

EV Chargers & Guns: Ensure safe outdoor operation under all weather conditions.

Customer Value:

Reduced rework and lower recall risk

Accelerated product launch timelines

Assurance of road-ready durability

Q1: Will small specimens move during turntable rotation or under water pressure?

IPX9K test chambers use specialized clamps to secure small specimens, preventing displacement and ensuring stable, repeatable testing.

Q2: How long can one full water tank support testing?

The IPX9K test equipment uses a closed-loop water circulation system. One full tank supports long continuous tests while maintaining stable flow and pressure.

Q3: Can customers drill holes in the Rain Test Chamber?

Self-drilling is not recommended due to internal components. If a custom hole is needed, contact us for a safe, non-standard solution.

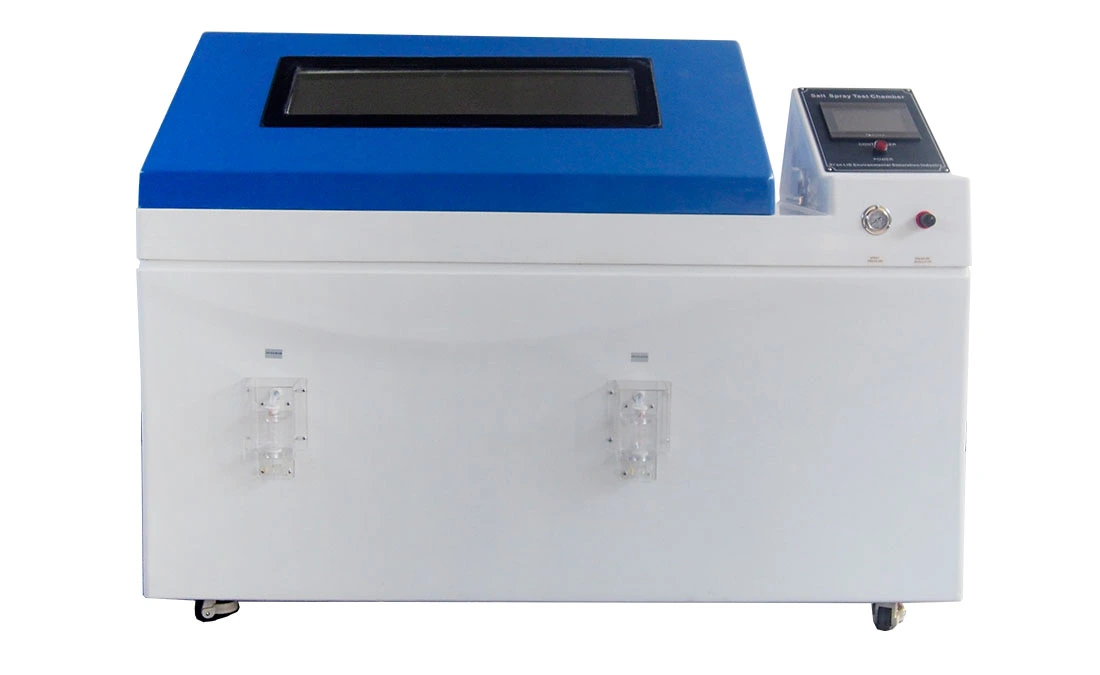

Q4: Does LIB provide a full range of rain and dust testing equipment?

Yes. LIB Industry offers a complete lineup of IP testing solutions, covering IPX1 to IPX9K for water ingress and IP5X/IP6X for sand and dust tests. We can customize test chambers—including shell-less designs—to meet your specific component or system requirements, creating your own dedicated IP test solution.

LIB Industry has served leading international automotive OEMs and laboratories, providing trusted IPX9K testing solutions worldwide.

Service Commitment:

3-year warranty

24-hour response time

Free technical training

“Pitfall Comparison” Box: Compare LIB equipment with low-cost alternatives, highlighting nozzle durability and pressure stability.

Iconography: Convert ISO standard parameters into intuitive visual symbols.

Expert Quote: “Reliability testing isn’t a blind gamble—LIB’s repeatable precision is the core asset of any lab.”

If you are building an ISO 20653-compliant lab, click inquiry@libtestchamber.com to contact us today.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia