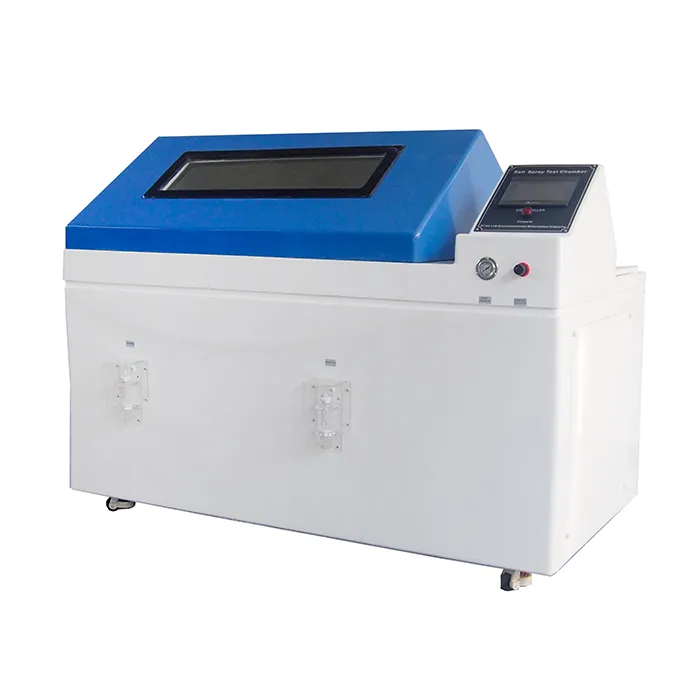

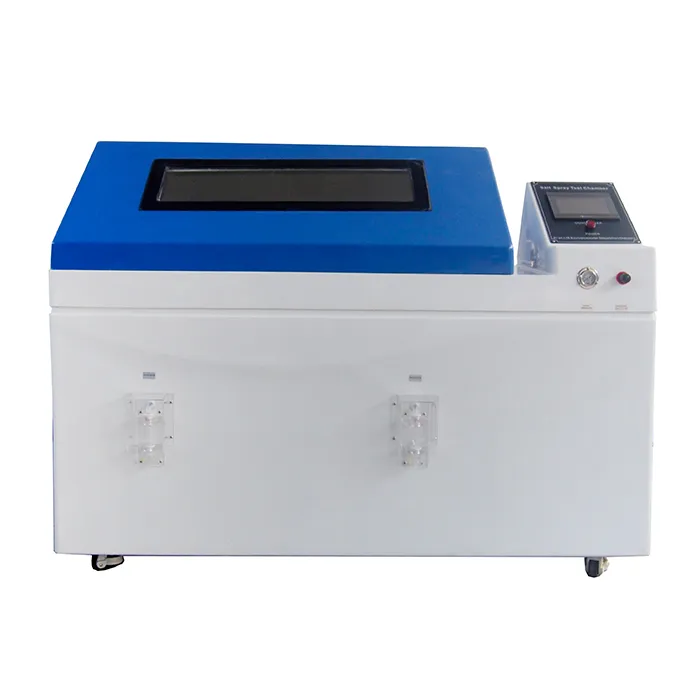

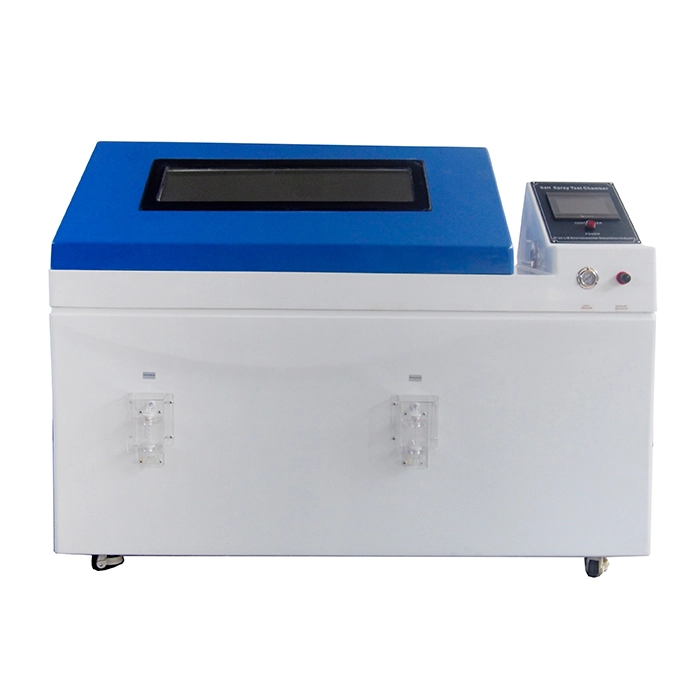

Salt Fog Corrosion Tester Machine Features and Benefits

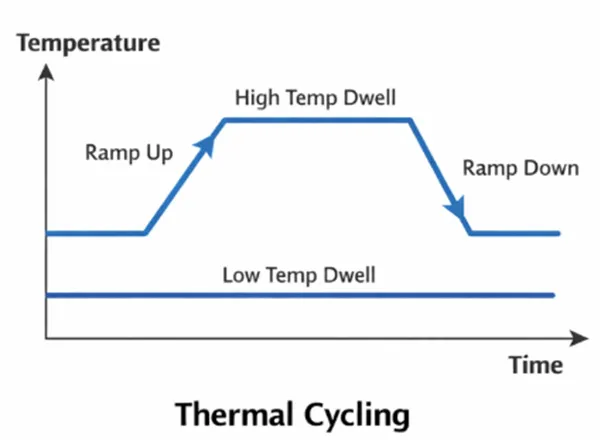

1. Multi-test mode integration

One device can complete various salt spray tests such as NSS, ASS, and CASS, covering from neutral to acidic and copper accelerated tests, meeting the requirements of different materials, coatings, and standards.

2. Precise and stable spray system

5% salt solution is atomized into uniform and fine salt spray particles, ensuring the consistency of the spray surface for the sample, stable spray volume and settling rate, suitable for long-term corrosion resistance evaluation.

3. Corrosion-resistant structural design

Made of glass fiber reinforced plastic (FRP), it has excellent corrosion resistance and durability, capable of working in a high-humidity salt spray environment for a long time without being corroded. Suitable for long-term testing and frequent use.

4. Wide operating range and optional functions

Temperature range from normal temperature to +60℃, humidity up to ≥95%RH, can meet most salt spray test standards.

Optional configurations include adjustable humidity function and SO₂ gas corrosion test function, suitable for multiple industries such as automotive components, electronic devices, and metal coatings.

Technical Specifications of Salt Fog Corrosion Tester Machine

Model | S-150 | S-250 | S-750 | S-010 |

Internal dimensions (mm) | 590*470*400 | 1000*640*500 | 1100*750*500 | 1000*1300*600 |

Overall dimensions (mm) | 1460*760*1140 | 1850*960*1350 | 1950*1030*1350 | 2000×1300×1600 |

Interior Volume (L) | 110 | 320 | 410 | 780 |

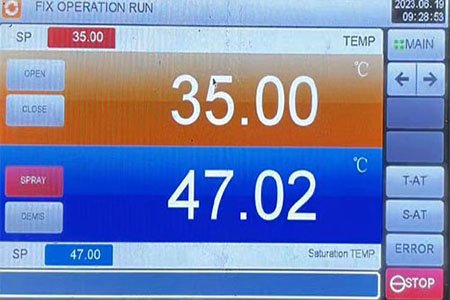

Temperature Range | Ambient ~ +60 ℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Humidity Range | 95% ~ 98% RH |

Salt Fog Deposition | 1~2ml / 80cm2 · h |

Spray Type | Continuous / Periodic |

Salt Fog Collected | Fog collector and fog measure cylinder |

Air Preheating | Saturated air barrel |

Spraying System | Atomizer tower and Spray nozzles |

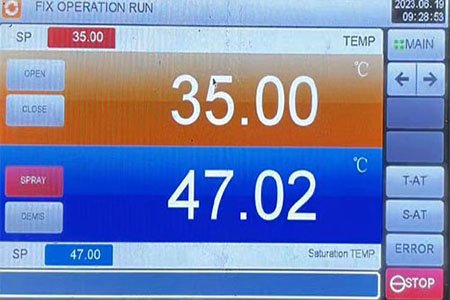

Controller | PID controller |

Safety Device | Humidifier Dry-combustion Protection; Over-temperature Protection; Over-current Protection; Water Shortage Protection; Earth leakage Protection |

Material | Glass fiber reinforced plastics |

Standard Configuration | 6 round bars and 5 V-shaped grooves |

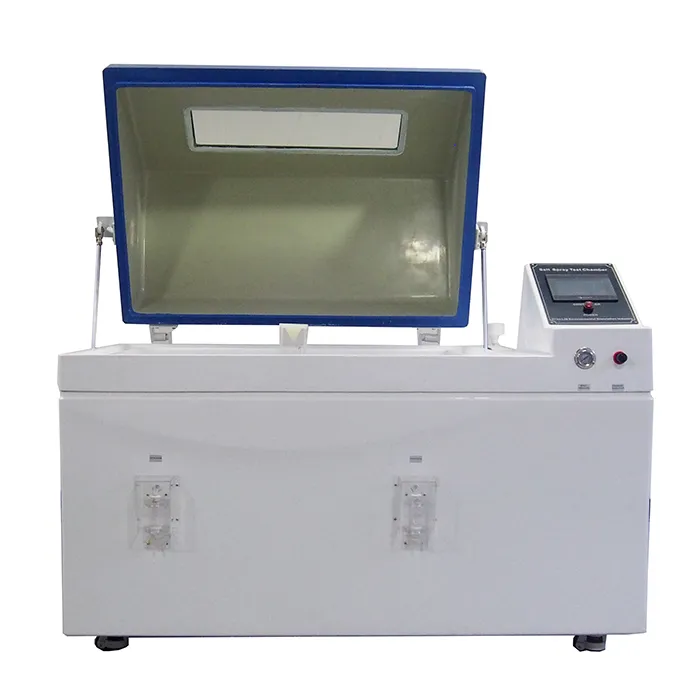

Details of Salt Fog Corrosion Tester Machine

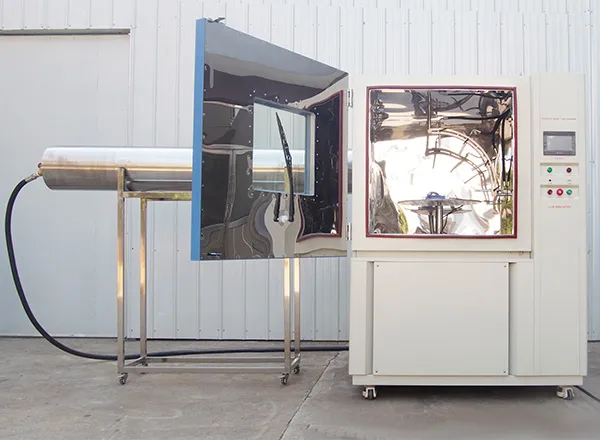

Spray System | Spraying method: Tower-type spraying is adopted to ensure that the spray particles are fine and uniform, without blocking the nozzles, and the quartz nozzles are easy to clean. Salt solution concentration: Supports standard 5% NaCl solution, and the concentration can be adjusted to meet different standards. Particle size of spray: Average 1-5 μm, settling rate 1.0-2.0 mL/80 cm²/h.

|

|

Sample Holder | Round rod + V-shaped groove design material, corrosion-resistant, adjustable angle, salt spray does not easily deposit on the test piece. Custom sample holders: insert type, 3D type... meet the needs of different test pieces.

|  |

Control System | Intelligent Control: Touch-screen PLC controller, with an intuitive interface and precise adjustment of multiple parameters. Real-time Monitoring and Protection: Equipped with multi-point monitoring and alarm functions for temperature, humidity, liquid level, etc., ensuring the safe and stable operation of the test. Data Function: Capable of data recording, USB export, and remote monitoring.

|  |

Salt Solution Agitation System | Function: Continuously ejecting bubbles from the pipeline maintain the uniformity of the salt solution concentration, preventing salting out and deposition. Material: Made of corrosion-resistant materials, suitable for long-term salt spray environment.

|  |

Ready to enhance your corrosion testing? Contact LIB today to get detailed technical info of salt fog corrosion tester machine, confirm quick delivery schedules, and enjoy our 3-year warranty with lifetime service support.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia