With automotive technology evolving rapidly—spanning electrification, lightweight materials, advanced driver-assistance systems (ADAS), and smart electronic modules—the need for rigorous testing has never been greater. Environmental testing ensures that components, assemblies, and systems perform reliably under extreme, real-world conditions.

LIB Industry, with over 16 years of experience in environmental test chambers, delivers cutting-edge solutions for automotive research, production validation, and global compliance. By combining advanced equipment, precise control, and customized chamber designs, LIB Industry ensures automotive components meet the highest standards of reliability and performance.

Automotive parts such as body panels, chassis components, fasteners, and electronic enclosures are exposed to harsh environmental conditions, including rain, salt, and pollutants. Corrosion testing replicates these conditions to assess protective coatings, metal durability, and overall product longevity.

Unlike traditional constant-exposure salt spray tests, modern cyclic corrosion testing simulates real-world wet-dry cycles, making laboratory results more predictive of actual field performance.

· ASTM B117 – Neutral Salt Spray: The most widely recognized method for evaluating corrosion resistance of coatings and metals under a continuous salt fog.

· ISO 9227 – NSS, AASS, CASS: Internationally recognized methods that include neutral, acidic, and copper-accelerated salt spray, suitable for automotive coatings and fasteners.

· VDA 233-102 – Cyclic Corrosion Test: Specifically designed for the automotive industry, simulates realistic wet-dry cycles combined with temperature variations to mimic road and climatic conditions.

· GM 9540P & Ford CETP 00.00-L-467: OEM-specific corrosion protocols ensuring compliance with manufacturer-specific durability requirements.

Features: - Temperature: Ambient ~ +60℃ - Spray rate: 1–2 mL/80cm²/h - Test volume: 110–1600 L - Construction: corrosion-resistant FRP - Applications: parts, electronics, protective metal coatings |  |

- High corrosion resistance ensures long service life

- Uniform spray and temperature distribution provide reliable test results

- Easy maintenance and intuitive control panel for convenient operation

- Energy-efficient design reduces operational costs

- SO₂ Test Chamber (ISO 6988) – for simulating industrial sulfur pollution and vehicle exhaust effects on metals

- Ozone Chamber (ASTM D1149) – evaluates degradation of coatings, rubber, and polymers exposed to atmospheric ozone

- Noxious Gas Chamber – allows controlled exposure to gases like NOx or SOx for accelerated corrosion assessment

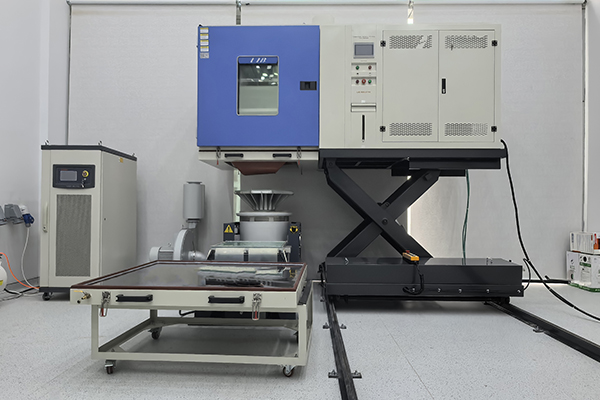

LIB vibration and climatic chambers test components under simulated real-world conditions—including operational vibrations, transportation shocks, temperature fluctuations, and humidity cycles. Typical applications include: - Electronic control units (ECUs) - Battery packs and charging modules - Sensors and actuators - Interior electronics

· IEC 60068-2-64 / 2-6 – Define methods for sinusoidal and random vibration tests to ensure automotive electronics can withstand road and operational vibrations.

· ISO 16750-3 – Automotive-specific vibration and mechanical stress standard for electrical and electronic components, widely used by OEMs for product validation.

· MIL-STD-810H – Military standard adapted for high-stress vibration and shock testing, often referenced in automotive applications for high-reliability components.

Parameters · Temperature range: –70°C to +150°C · Humidity range: 20–98% RH · Vibration frequency: 5–3000 Hz, acceleration: 3–80 g · Programmable profiles: up to 200 patterns · Load capacity: customizable per chamber size |  |

- Simulates real-world conditions accurately to predict component reliability

- Multi-functional design supports vibration, temperature, and humidity testing in a single unit

- Programmable cycles for automated, repeatable tests

- Sturdy construction for long-term operation and high load capacity

Thermal shock testing evaluates the ability of electronic components, LEDs, and automotive assemblies to withstand sudden temperature transitions, ensuring environmental reliability under rapid hot-cold cycles.

· IEC 60068-2-14 – Temperature Shock: International standard for assessing product resistance to rapid temperature changes, simulating harsh climatic conditions.

· JASO D 014 – Automotive Thermal Performance: Japanese Automotive Standard for temperature shock in automotive electronics and connectors.

· ISO 16750-4 – Electrical and Electronic Components: Specifies environmental testing requirements for electrical components, including thermal cycling and shock.

Parameters · Hot zone: +220°C · Cold zone: –75°C · Transfer time: ≤10 seconds · Basket capacity: 5–50 kg · Applications: automotive electronics, connectors, sensors, lighting |  |

- Rapid temperature transition for realistic thermal stress testing

- High uniformity ensures accurate results across multiple samples

- Compact design with high basket capacity supports diverse component sizes

- User-friendly interface for easy programming and monitoring

· Headlights, camera modules, connectors, charging ports, ECUs

· Assessing dustproof, waterproof performance, and service life

· IEC 60529 – IP5X/IP6X: Defines protection levels against solid particle ingress. IP5X indicates protection against dust limited ingress; IP6X indicates complete dust-tightness.

· ISO 20653 – Automotive Dust Protection: Specifically targets vehicle components and validates ingress protection under real automotive conditions.

· MIL-STD-810H – Sand/Dust Testing: Military-derived standard often used for high-reliability automotive components exposed to desert or dusty environments.

Features: - Dust type: Arizona sand, talc - Concentration: 2–10 g/m³ - Airflow: 1–20 m/s - Programmable cycles for realistic simulation |  |

· IPX3/IPX4 – Low-pressure water spray

· IPX5/IPX6 – High-pressure water jets, simulating car wash and rain

· IPX7/IPX8 – Immersion tests

· IPX9K – High-pressure, high-temperature wash (truck and bus applications)

· JIS D0203 – Rain Test: Japanese standard for evaluating water resistance of vehicle parts

Sunlight, UV exposure, and environmental radiation cause color fading, cracking, and material degradation. Accelerated weathering testing predicts long-term durability of:

- Plastics and polymer components

- Coatings and paints

- Interior and exterior trim

- Headlights and light diffusers

Xenon Testing:

- ASTM G155 – Simulates full-spectrum sunlight to evaluate outdoor durability of coatings, plastics, and composites.

- ISO 105-B02 – Provides guidance on light fastness testing for colored materials. - SAE J2527 – Automotive-specific standard for headlamps and exterior lighting exposure to UV radiation.

UV Testing:

- ASTM G154 – UV fluorescent lamp testing for accelerated polymer degradation. - ISO 4892-3 – International UV exposure standard for plastics, detailing lamp type, irradiance, and cycle settings.

- Irradiance: 35~150 W/㎡ - Temperature: Ambient ~ 100 ℃ ±2℃ - Humidity: 50% ~ 98% RH - Rotating sample rack for uniform exposure |  |

- Lamp type: UVA-340 / UVB-313 - Rated power: 40W × 8 - Temperature: Ambient ~ 90 ℃ ±2℃ |  |

· 16+ years of industry experience with 1000+ automotive testing projects

· Chambers meet ASTM, ISO, IEC, MIL, SAE, JIS global standards

· Customizable size, load, and environmental performance

· 3-year extended warranty and lifetime service

· Integrated features: PLC control, touchscreen interface, remote monitoring, data logging

· Comprehensive support for R&D, production validation, and regulatory compliance

LIB Industry delivers trusted, precision environmental test chambers for automotive components. From corrosion to thermal shock, IP ingress to accelerated weathering, LIB Industry ensures components perform reliably in all operating conditions, supporting global automotive standards and long-term durability.

Contact LIB Industry today inquiry@libtestchamber.com to design your custom environmental testing chamber and ensure your automotive components meet the highest standards for quality, reliability, and regulatory compliance.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia