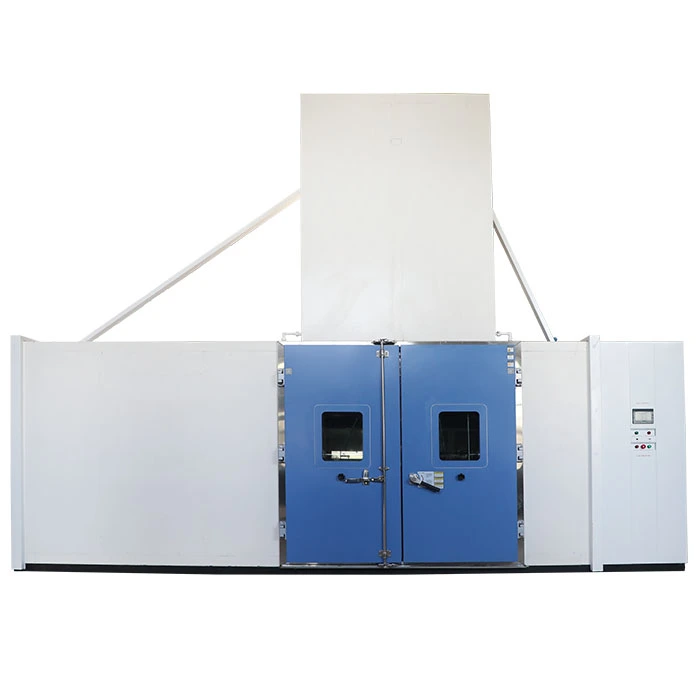

Walk-in Salt Spray Chamber Features and Benefits

1. Applicable to complete vehicles, home appliances, large metal components, etc., and meets the requirements of batch or whole piece testing.

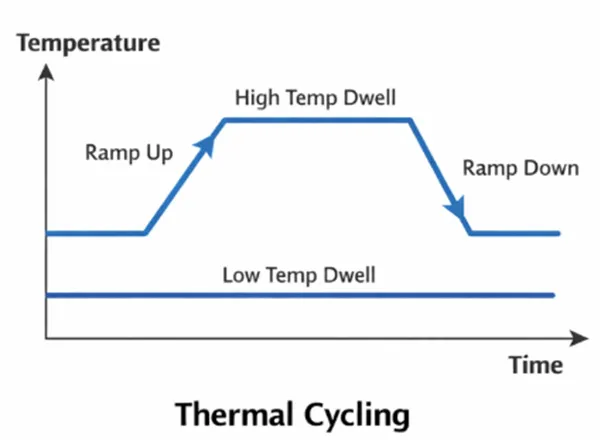

2. Precisely control temperature, humidity, spray time and intermittent cycle to achieve standardized and automated operation.

3. In addition to the traditional NSS test, it can also be expanded to conduct composite salt spray tests such as AASS and CASS, meeting standards such as ASTM B117, ISO 9227 and etc.

4. The wide temperature and humidity range (10℃ to 90℃, 30% to 98%RH) greatly expands the possibilities of the environment for salt spray corrosion simulation.

Specifications of Walk-in Salt Spray Chamber

Name | Walk-in Salt Spray Chamber |

Temperature Range | +10 ℃ ~ +90 ℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Humidity Range | 30% ~ 98% RH |

Humidity Deviation | + 2%, - 3% |

Salt Fog Deposition | 1~2ml / 80cm2 · h |

Cooling system | Mechanical compression refrigeration system |

Water supply system | Water purification system |

Air Preheating | Saturated air barrel |

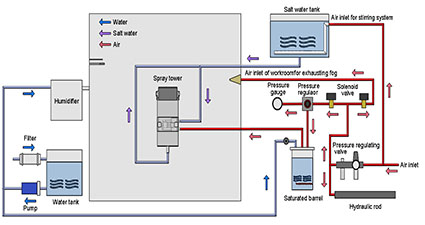

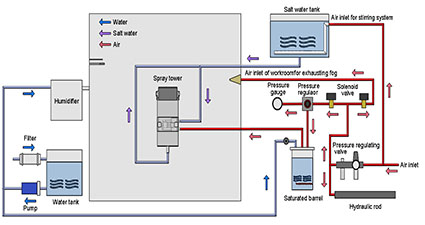

Spraying System | Atomizer tower and Spray nozzles |

Salt Fog Collected | Fog collector and fog measure cylinder |

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Air Circulation | Centrifugal wind fan |

Safety Device | Humidifier Dry-combustion Protection; Over-temperature Protection; Over-current Protection; Water Shortage Protection; Earth leakage Protection |

Material | SUS 304 stainless steel |

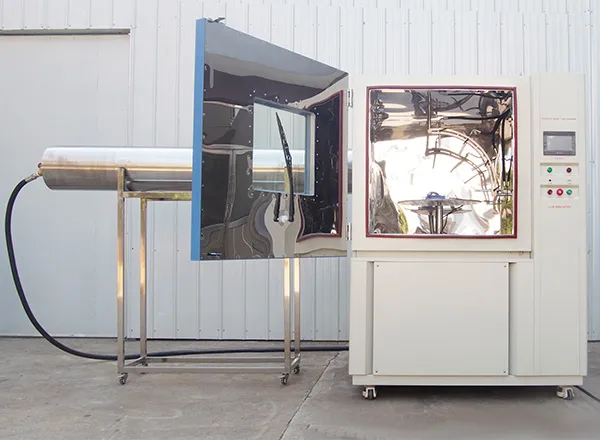

Details of Walk-in Salt Spray Chamber

|

Workroom | Salt Spray Tower |

SUS304 material, smooth and easy to clean, preventing the accumulation of corrosion residues. Resistant to high and low temperatures, high humidity and high salt spray corrosion. Sample racks, hangers or customized track systems can be installed. | Tower vertical structure, with built-in quartz nozzles to atomize the salt water and evenly distribute it. The quantity is determined according to the size of the working chamber. Continuous or intermittent spray control is possible. |

|  |

Salt Fog Collector | Air Circulation System |

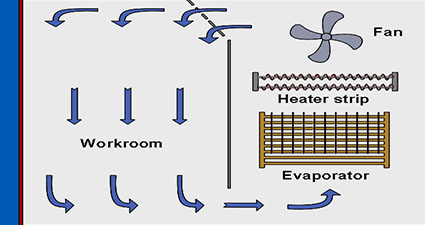

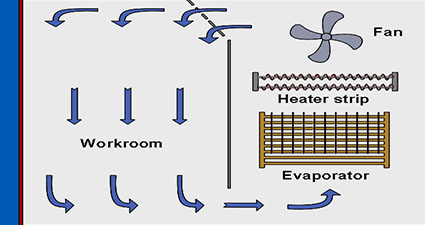

Monitor the sedimentation amount of salt spray during the test process. Use highly corrosion-resistant plastic, multiple placement positions, and the quantity is determined based on the capacity of the working chamber. | The air circulation system ensures the uniform distribution of environmental parameters such as salt spray, temperature and humidity in large-sized workrooms. |

|  |

PID Controller | Water circulation system |

The PID intelligent temperature control system enables users to set parameters such as temperature, spray time, and intermittent period through the touch screen. Supports multi-group program memory and automatic operation functions. | Fully automatic control, with liquid level sensors monitoring the water level in the water tank to ensure continuous spraying process. The water pump conveys the brine to the spray tower and is equipped with a filtering device to prevent the nozzles from clogging. |

|  |

LIB also offers walk-in customization for the S and SSC series. All products come with a 3-year warranty and lifetime service. Based on your test requirements, the size of the test site and other information, LIB provides you with tailor-made and timely test equipment solutions. Welcome to leave your test requirements!

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia